2025 Industry Tech Trends: How Best High Pressure Hoses Are Revolutionizing Efficiency and Safety

In recent years, the demand for High Pressure Hoses has surged, driven by advancements in industrial applications and the growing need for enhanced efficiency and safety. According to a report by MarketsandMarkets, the global market for high-pressure hoses is expected to reach $5.7 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2% from 2020. This growth is largely attributed to their critical role in various industries, including oil and gas, construction, and manufacturing. As manufacturers, particularly those from leading Chinese factories, innovate to create more durable and reliable high-pressure hoses, they are transforming operational standards worldwide. These advancements not only improve performance but also significantly reduce the risk of accidents, aligning with the industry's increasing focus on safety protocols. This blog delves into the critical trends shaping the future of high-pressure hose technologies and their impact on global industrial practices.

Emerging Applications of High Pressure Hoses in Critical Industries

High pressure hoses are becoming increasingly vital in various critical industries, driving improvements in both efficiency and safety. According to a recent report by MarketsandMarkets, the global high-pressure hose market is projected to grow at a CAGR of 5.5% through 2025, highlighting a rising demand in sectors like oil and gas, manufacturing, and construction. These hoses are designed to withstand intense pressure and harsh conditions, enabling industries to operate more effectively while minimizing the risk of equipment failure.

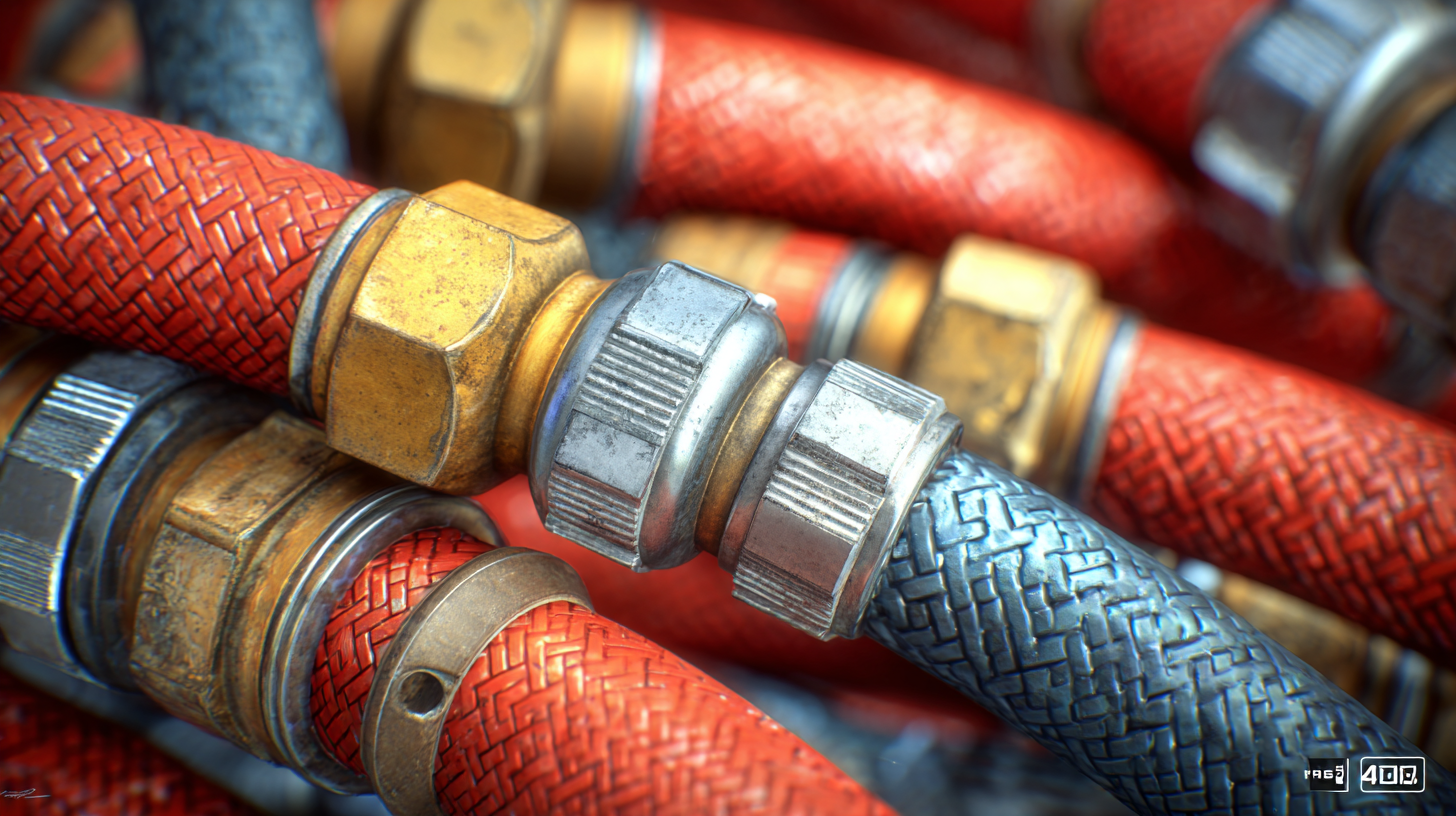

One significant application of high pressure hoses is in hydraulic systems, where they are essential for powering machinery with precision and reliability. The flexibility and durability of modern high pressure hoses allow for easier installation and maintenance, reducing downtime. Furthermore, they provide enhanced safety features, such as burst-resistant designs, which can prevent hazardous leaks and spills in environmentally sensitive areas.

Tips for selecting the right high pressure hose include assessing the specific pressure requirements of your application and choosing materials that are compatible with the fluids being transported. Investing in hoses with certifications for safety and performance can also ensure long-term reliability and reduced risk. By prioritizing these factors, companies can leverage high pressure hoses to optimize productivity while safeguarding their operations against unexpected failures.

Impact of Advanced Materials on High Pressure Hose Durability and Performance

The advent of advanced materials has significantly transformed the landscape of high pressure hoses, enhancing both their durability and performance. Traditional rubber hoses, while effective, often struggled with issues such as wear and tear, limiting their lifespan and effectiveness in demanding applications. However, innovations in materials science have led to the development of hoses made from specialized polymers and composites that can withstand extreme pressure and harsh conditions. These advanced materials not only extend the lifespan of high pressure hoses but also improve their resistance to environmental factors such as abrasion, chemicals, and temperature fluctuations, making them ideal for various industries.

Moreover, the performance of high pressure hoses has seen dramatic improvements due to these innovative materials. Modern hoses exhibit greater flexibility and lighter weight while maintaining their strength, allowing for easier handling and installation. This enhanced performance translates to increased operational efficiency, as equipment downtime due to hose failure is significantly reduced. The integration of advanced materials in high pressure hose construction promotes greater safety in manufacturing and engineering sectors, where high-stakes tasks demand reliable and durable equipment. As industries continue to prioritize safety and efficiency, the role of advanced materials in high pressure hose technology is poised to be pivotal in shaping future developments.

Analyzing Market Growth: Industry Demand for High Pressure Hoses by 2025

The demand for high-pressure hoses is projected to experience significant growth by 2025, driven by advancements in technology and an increasing focus on efficiency and safety across industries. As sectors like construction, oil and gas, and manufacturing expand, the reliance on durable and high-performance hoses will intensify. These hoses are engineered to withstand extreme pressure, ensuring that operations can run smoothly without the risk of rupture or failure. Additionally, innovations in materials and design have enhanced the durability and versatility of high-pressure hoses, making them essential in both existing and emerging applications.

Market analysis indicates that the surge in demand will be fueled not only by industrial growth but also by the rising awareness of safety protocols. High-pressure hoses play a crucial role in minimizing operational hazards, particularly in environments where pressure management is critical. As industries prioritize worker safety and regulatory compliance, the integration of advanced high-pressure hose systems will become more prevalent. With these improvements, organizations can expect increased operational efficiency and a significant reduction in downtime, positioning high-pressure hoses as a foundational element for success in the industrial landscape of 2025.

2025 Industry Tech Trends: How Best High Pressure Hoses Are Revolutionizing Efficiency and Safety

| Application Area | Market Growth (2020-2025) | Safety Improvements | Industry Demand (Units) |

|---|---|---|---|

| Construction | 15% CAGR | 40% reduction in incidents | 1.5 million |

| Manufacturing | 12% CAGR | 30% safety enhancement | 2.0 million |

| Oil & Gas | 10% CAGR | 25% decrease in leaks | 900,000 |

| Automotive | 18% CAGR | 35% improvement in system reliability | 1.2 million |

| Aerospace | 20% CAGR | 50% reduction in emergency landings | 300,000 |

Safety Innovations in High Pressure Hose Technology: A Data-Driven Perspective

In recent years, the high pressure hose industry has witnessed remarkable innovations aimed at enhancing safety and operational efficiency. With increasing demands across various sectors, advancements in materials and design have propelled these hoses to new heights. Safety innovations in high pressure hose technology are not just theoretical; they are backed by comprehensive data demonstrating their effectiveness. For instance, the introduction of advanced composite materials has resulted in hoses that withstand higher pressures while minimizing the risk of failure, offering both durability and reliability in demanding environments.

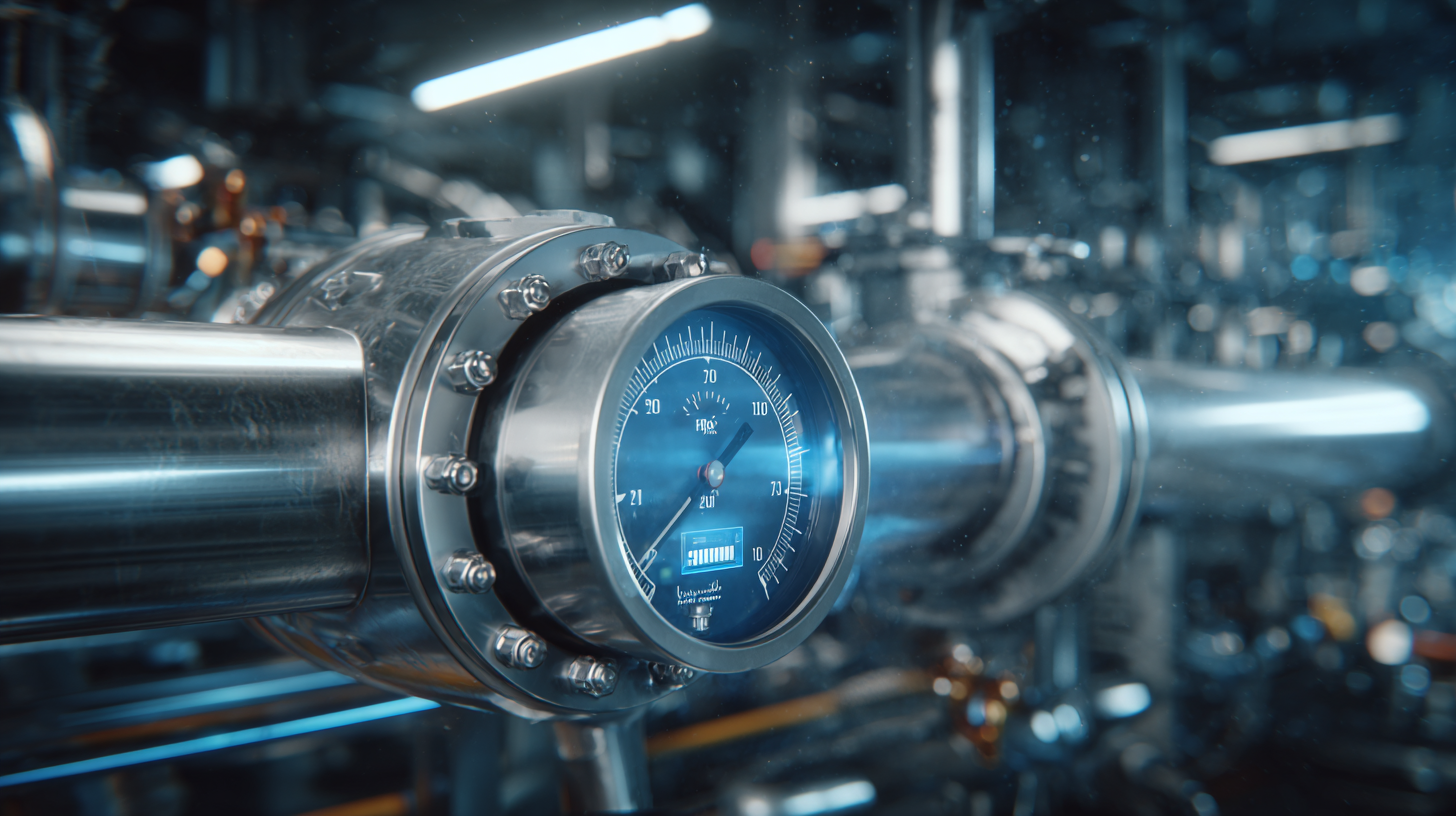

Moreover, manufacturers are now incorporating smart technology into high pressure hoses. These innovations include sensors that monitor pressure levels and provide real-time data analytics, allowing users to preemptively address potential issues before they escalate into hazardous situations. This data-driven perspective not only helps in maintaining optimal performance but also significantly reduces the likelihood of accidents related to hose failures. By harnessing these technological advancements, industries can ensure safer operations, protect their workforce, and ultimately improve overall productivity.

Efficiency Metrics: Cost Savings Through Modern High Pressure Hose Solutions

Innovations in high pressure hose technology are transforming industries by significantly enhancing efficiency and safety standards. Modern high pressure hoses, designed with advanced materials and engineering techniques, offer higher durability, lighter weight, and greater resistance to various chemicals and temperatures. These improvements not only reduce the risk of failures and accidents but also contribute to streamlined operations. Companies that adopt these advanced hose solutions are witnessing marked reductions in downtime, leading to substantial cost savings.

Moreover, the implementation of modern high pressure hose systems lowers maintenance costs and extends the lifespan of equipment. With features like optimized flow rates and lower friction losses, businesses can achieve better operational efficiency, translating into impressive overall savings. By minimizing leaks and bursts — common issues with older hose models — organizations enhance workplace safety while also complying with stringent regulations. This holistic approach to employing high pressure hose technology not only supports the bottom line but also fosters a safer workplace for employees, illustrating a comprehensive strategy for success in the modern industrial landscape.

2025 Industry Tech Trends: High Pressure Hoses Efficiency Metrics

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com