Best Hydraulic Distributor Options for Efficient Fluid Control?

Fluid control is crucial in various industries. The choice of a Hydraulic Distributor significantly impacts efficiency and performance. Industry expert John Thompson emphasizes, "Selecting the right Hydraulic Distributor can make or break your system's effectiveness."

Hydraulic Distributors regulate fluid flow in machinery. They affect everything from speed to pressure. The wrong distributor can lead to inefficiencies and increased costs.

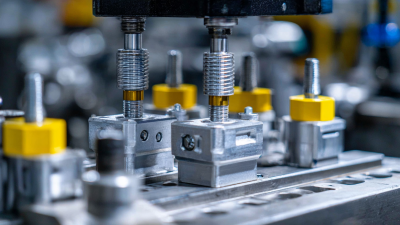

Many options exist, yet identifying the best one is challenging. Features like compatibility and load capacity are vital. Companies must evaluate various models carefully. Too often, rushed choices lead to regrets. A thorough assessment can prevent costly mistakes.

Understanding the Role of Hydraulic Distributors in Fluid Control

Hydraulic distributors play a crucial role in fluid control systems. They manage the flow and direction of hydraulic fluid effectively. This management ensures that machinery operates smoothly and efficiently. Several designs are available, each with unique features. Selecting the right distributor impacts overall system performance significantly.

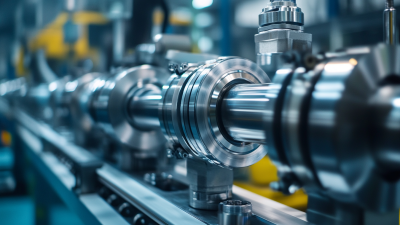

Understanding the components of hydraulic distributors is essential. Often, they consist of various valves and actuators. These parts work together to channel fluids precisely where needed. A well-designed distributor can enhance response times. However, improper selection can lead to inefficiencies. It is vital to assess system requirements carefully.

Fluid control might seem straightforward, yet complexities abound. Over time, wear and tear can affect performance. Regular maintenance is necessary to avoid unexpected failures. Operators should periodically inspect distributors for signs of damage. Upgrading to more efficient models may also be beneficial. Just remember, effective fluid control is a continuous process.

Key Features to Look for in Hydraulic Distributors

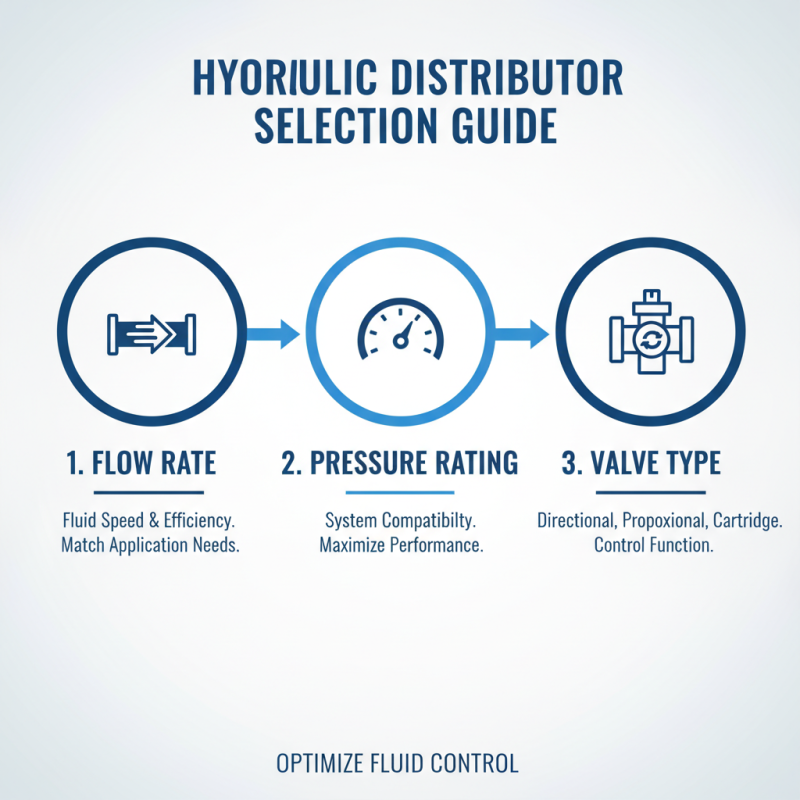

When selecting a hydraulic distributor, several key features are crucial for efficient fluid control. The flow rate is the first aspect to consider. It determines how quickly the hydraulic fluid moves through the system. Higher flow rates can improve efficiency, but it’s essential to match them with the application’s requirements.

Next, the size and type of ports can impact overall performance. Larger ports allow for better flow, reducing resistance. However, the wrong size can create leaks. Material composition is another factor. Durability matters significantly in high-pressure environments. Some materials can corrode or weaken over time, leading to failures.

Also, consider ease of maintenance. A distributor that requires frequent servicing can hinder operations. It’s vital to assess design features that facilitate easy access to critical components. While many distributors perform adequately, some may not meet long-term needs. Always reflect on how the chosen distributor aligns with your system's unique demands. Making the right choice isn’t always straightforward, and it often calls for thorough evaluation.

Types of Hydraulic Distributors: A Comprehensive Overview

Hydraulic distributors play a crucial role in fluid control systems. They are essential for directing fluid flow in hydraulic circuits. The type of distributor selected can significantly impact system efficiency and performance. Studies indicate that choosing the right hydraulic distributor can improve system efficiency by up to 30%. This data highlights the importance of making informed decisions.

There are several types of hydraulic distributors available, each with unique functions. Directional control valves are common; they control the flow direction of hydraulic fluid. Pressure control valves maintain system pressure and prevent overload. Flow control valves regulate fluid speed in the system. However, not every distributor is suitable for all applications. Engineers must consider factors such as fluid viscosity, temperature, and application requirements.

Mistakes in selecting hydraulic distributors can lead to inefficiency. Sometimes, operators focus too much on cost savings. This can cause issues like increased wear and tear or maintenance needs. An improper distributor can result in pressure losses. Consequently, it is essential to evaluate the operational requirements carefully. Investing time in understanding hydraulic distributor types can yield better long-term results for fluid control systems.

Top Brands and Models for Reliable Hydraulic Distribution

When selecting hydraulic distributors, reliability is key. Several brands stand out in the market. They offer various models tailored for different applications. Efficient fluid control relies on these distributors to manage hydraulic systems effectively. A variety of options exist, each designed for specific pressures and flow rates.

The right choice ensures optimal performance. Users often overlook compatibility with existing systems. This can lead to inefficiencies and increased costs. A well-designed hydraulic distributor enhances productivity. Features like adjustable flow control or quick-connect fittings can make a significant difference. Additionally, ease of maintenance is crucial, as it influences long-term operation.

Investing in quality distribution solutions pays off. However, make sure to assess your unique needs. Not every model suits every application. Users should reflect on past experiences. Identifying potential pitfalls can guide future decisions. Prioritizing function over brand hype may yield better results. Each project demands a thoughtful approach to hydraulic distribution.

Hydraulic Distributor Options for Efficient Fluid Control

Best Practices for Selecting and Maintaining Hydraulic Distributors

When selecting hydraulic distributors, focus on flexibility and compatibility. Different applications require varying flow rates and pressure levels. Ensure the distributor you choose can handle your system's specific needs. Check connection types and sizes to avoid mismatches. It’s essential to know the working environment as well. Temperature and contaminants can affect performance.

Maintenance is equally crucial. Regular inspections can reveal leaks or malfunctions. Keep the area around the distributor clean to prevent buildup. Small issues can escalate quickly. Implement a routine schedule for replacing fluid and filters. This helps maintain efficiency over time. Consider documenting these practices to identify patterns or repeated issues. Reflection on past maintenance can lead to better future decisions.

Best Hydraulic Distributor Options for Efficient Fluid Control

| Feature | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Flow Rate (L/min) | 20 | 30 | 40 |

| Maximum Pressure (bar) | 210 | 250 | 300 |

| Temperature Range (°C) | -20 to 80 | -15 to 90 | -10 to 100 |

| Weight (kg) | 5 | 7 | 9 |

| Material | Aluminum | Steel | Composite |

| Maintenance Interval (h) | 1000 | 1200 | 1500 |

Related Posts

-

5 Reasons Why Our Best Hydraulic Parts Outperform Competitors by 70% in Performance Tests

-

Ultimate Guide to Choosing the Best Hydraulic Distributor Comparison Analysis for Global Buyers

-

Essential Tips for Selecting Top Quality Fluid Power Hydraulics Suppliers: A Data-Driven Approach

-

Essential Checklist for Choosing the Right Hydraulic Piston Pump for Your Applications

-

Top Strategies for Selecting the Best Hydraulic Equipment Repair Services Worldwide

-

Unlocking the Future: Innovative Applications of Fluid Power Hydraulics in Modern Industry

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com