10 Best Tips for Effective Hydraulic Piston Repair Techniques

In the realm of industrial maintenance, effective Hydraulic Piston Repair has become increasingly crucial as machinery continues to evolve in complexity and precision. According to a report by the International Journal of Hydraulic Engineering, improper maintenance can lead to a staggering 30% reduction in equipment lifespan, underscoring the importance of adept repair techniques. Moreover, the Fluid Power Journal highlights that nearly 70% of hydraulic system failures are attributed to inadequate repairs, emphasizing the need for best practices in the field. As industries strive for heightened efficiency and reduced downtime, mastering repair techniques not only enhances operational sustainability but also significantly cuts costs associated with equipment replacement. This guide presents the 10 best tips aimed at optimizing hydraulic piston repair processes, ensuring that professionals are well-equipped to tackle the challenges associated with hydraulic systems.

Understanding Hydraulic Piston Mechanics for Effective Repairs

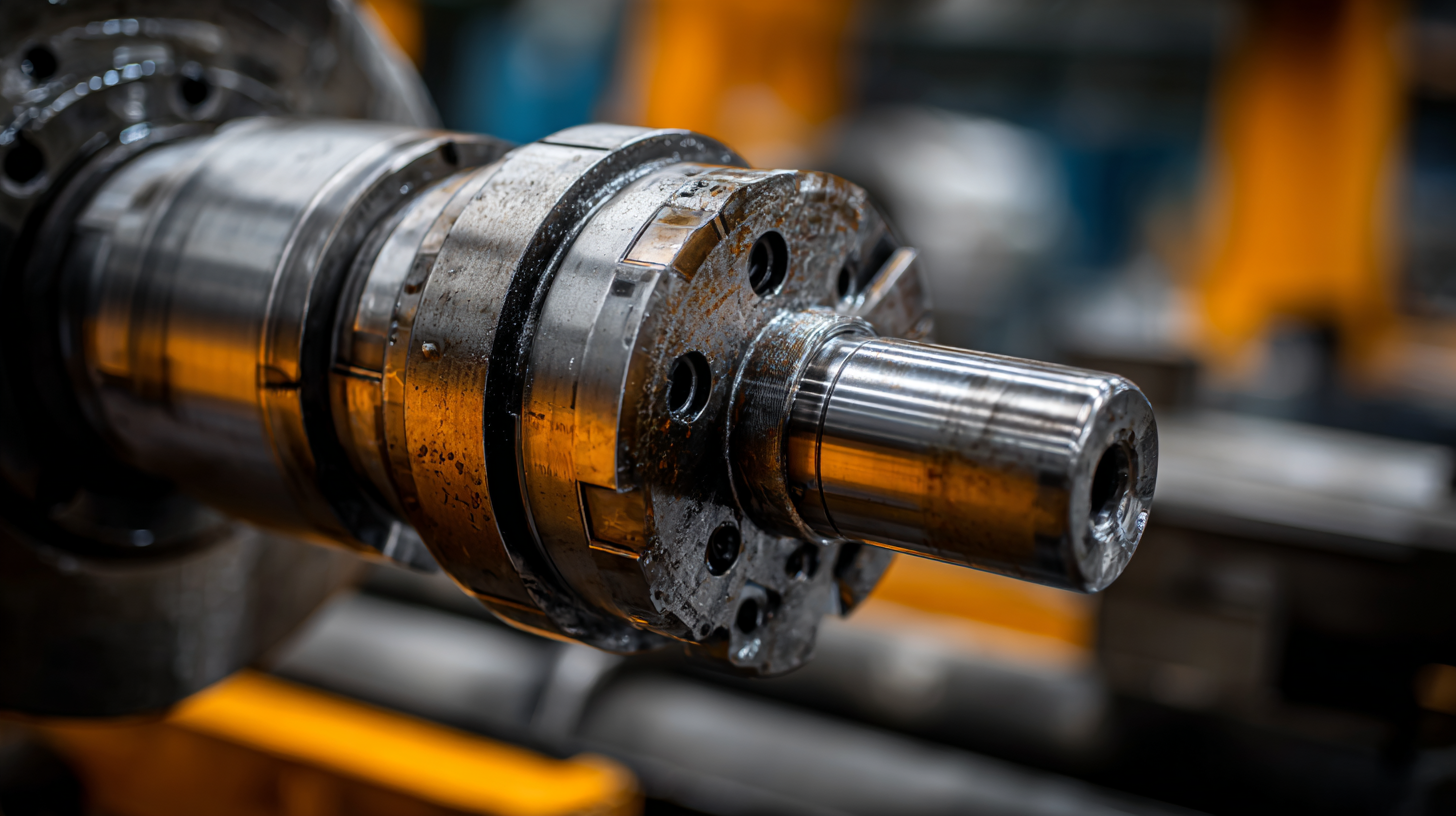

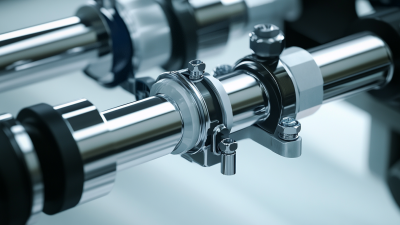

Understanding hydraulic piston mechanics is crucial for anyone involved in repair techniques. The hydraulic piston operates on the principle of fluid mechanics, where incompressible liquids transmit force efficiently. Each component, from the cylinder to the piston seal, plays a vital role in ensuring optimal functionality. Familiarity with the design and operation of these components helps technicians diagnose issues more accurately and implement effective repairs.

Understanding hydraulic piston mechanics is crucial for anyone involved in repair techniques. The hydraulic piston operates on the principle of fluid mechanics, where incompressible liquids transmit force efficiently. Each component, from the cylinder to the piston seal, plays a vital role in ensuring optimal functionality. Familiarity with the design and operation of these components helps technicians diagnose issues more accurately and implement effective repairs.

Effective repairs begin with assessing common failure points, such as leakage or abnormal wear on seals. Understanding the mechanics allows technicians to identify whether the problem arises from improper installation, insufficient lubrication, or contamination in the hydraulic fluid. By appreciating the dynamics of pressure and volume within hydraulic systems, repair specialists can choose the right materials and techniques for rebuilding or replacing hydraulic pistons, ensuring longevity and reliability in performance. This foundational knowledge empowers technicians to make informed decisions, thereby increasing the efficiency and success rate of their repair work.

Essential Tools for Hydraulic Piston Repair Success

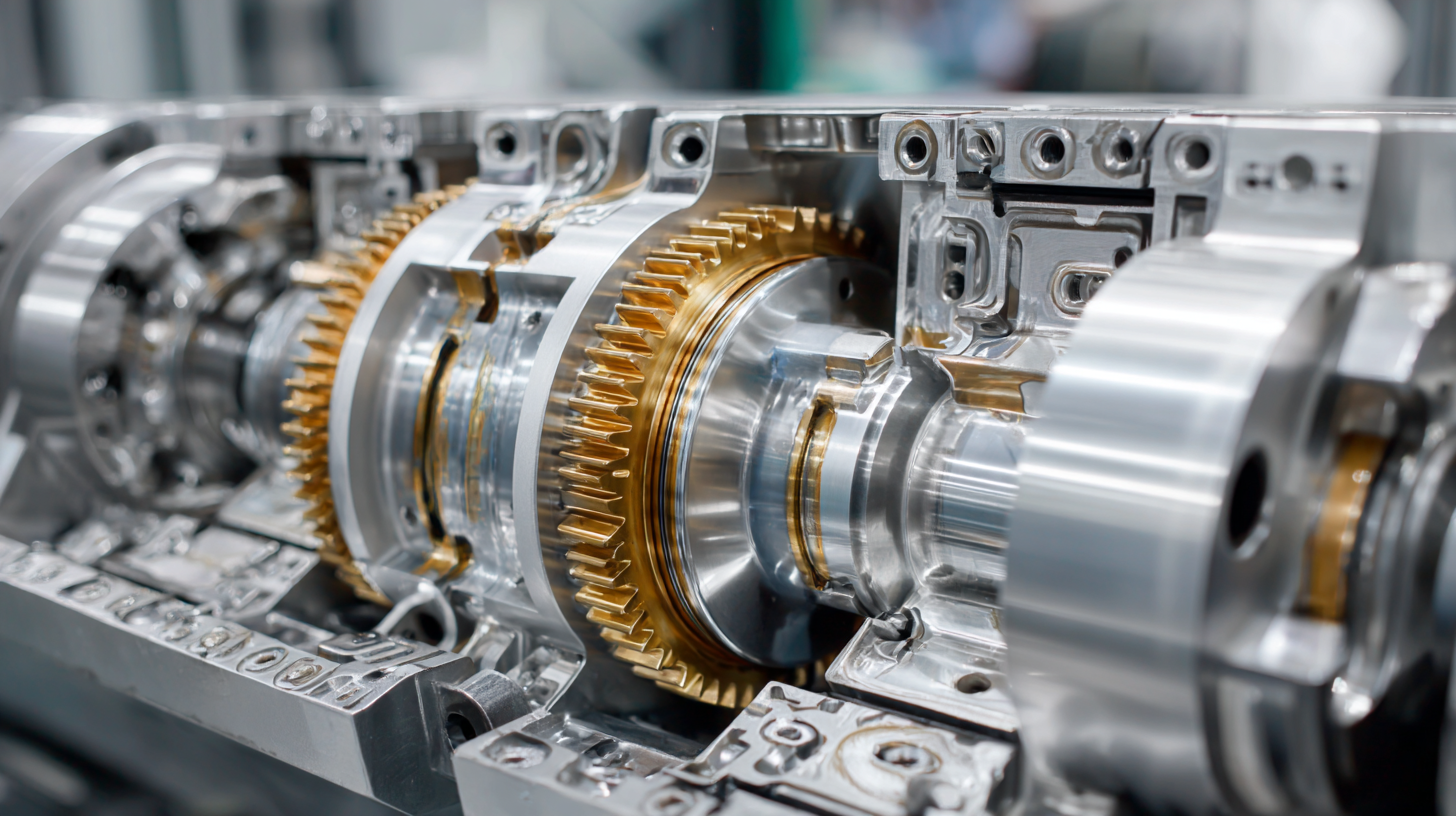

When it comes to hydraulic piston repair, having the right tools on hand is crucial for success. Essential tools such as hydraulic jacks, torque wrenches, and specialized seal removal kits play a significant role in ensuring that repairs are conducted efficiently and effectively. According to the Hydraulic Institute, an inefficient repair process can lead to increased downtime, costing companies upwards of $100,000 per hour in lost productivity. Therefore, investing in high-quality tools not only enhances the repair quality but also minimizes costly disruptions.

Additionally, using diagnostic tools like hydraulic system analyzers can aid technicians in identifying issues quickly. A comprehensive report by Machinery Lubrication indicates that up to 70% of hydraulic system failures stem from inadequate maintenance practices, emphasizing the importance of employing the right tools for precise diagnostics and repair. By ensuring that your toolkit is equipped with these essential instruments, you can significantly increase your repair success rate and extend the lifespan of hydraulic components, ultimately leading to reduced operational costs and increased efficiency in hydraulic systems.

10 Best Tips for Effective Hydraulic Piston Repair Techniques

Common Issues in Hydraulic Pistons and How to Address Them

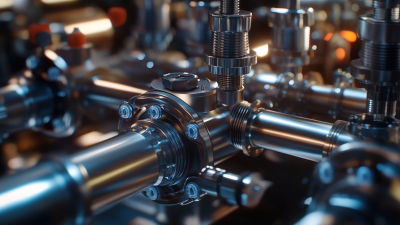

Hydraulic pistons are vital components in numerous machinery and systems, and they can encounter various issues that affect performance. Common problems include leaks, excessive wear, and failure to generate pressure, often resulting from contaminated hydraulic fluid, inadequate lubrication, or general neglect in maintenance. Identifying these issues early is crucial, as they can lead to more significant failures and costly repairs.

To address these common concerns, the first step is regular inspection and maintenance of the hydraulic system. Checking for signs of wear or leaks can help catch issues before they escalate. Additionally, using high-quality hydraulic fluid and keeping it free from contaminants is essential for ensuring smooth operation. If a piston shows signs of damage, it may be possible to repair it by replacing seals or other worn components rather than undergoing a complete overhaul, which can save both time and resources. By following these effective repair techniques, operators can enhance the longevity and efficiency of their hydraulic systems.

Step-by-Step Techniques for Inspecting Hydraulic Pistons

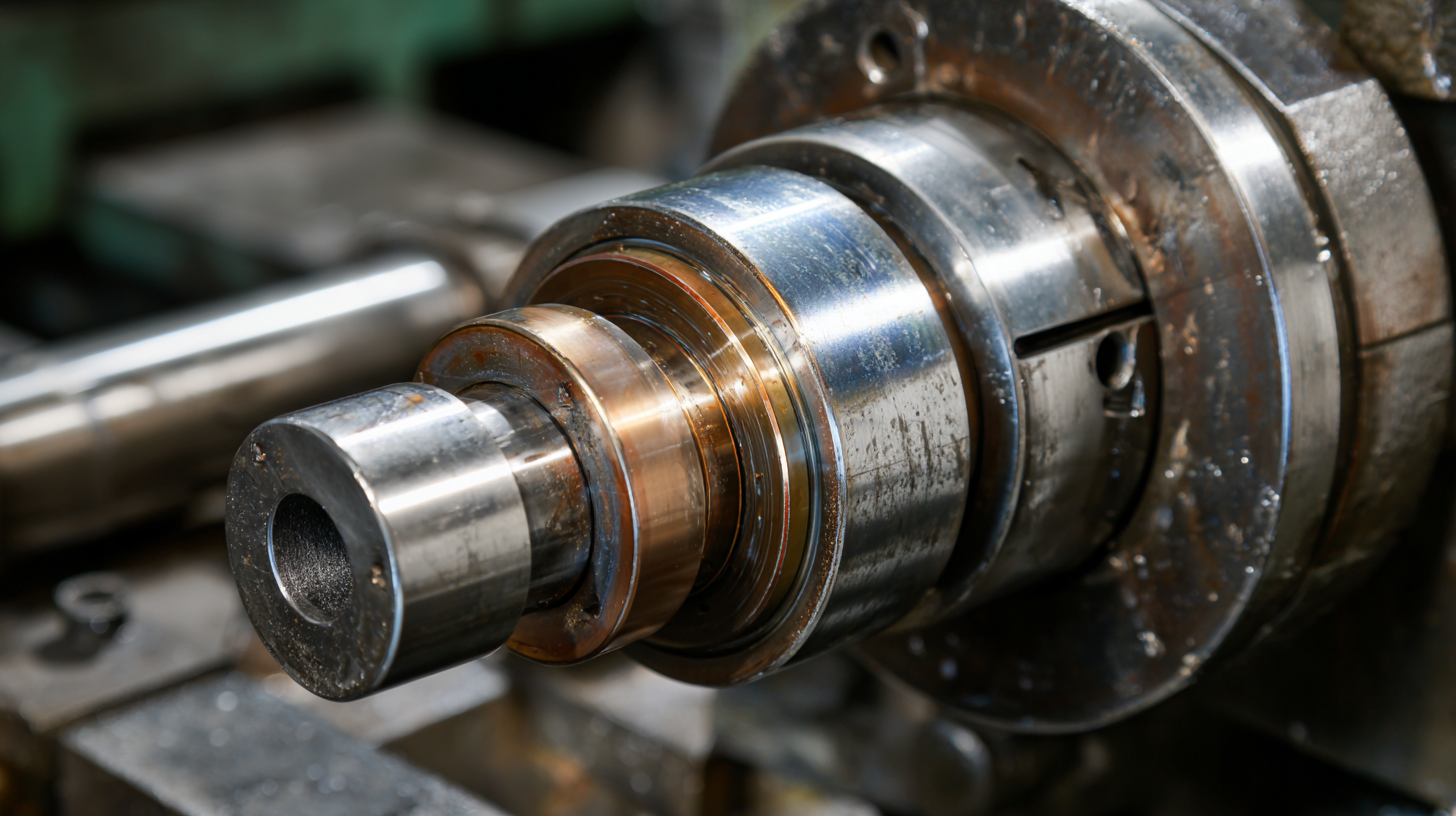

Inspecting hydraulic pistons is crucial for ensuring optimal performance in various applications, from construction equipment to aerospace. A systematic approach involves several steps that can significantly enhance the reliability of hydraulic systems. Firstly, visual inspection should be prioritized; look for signs of abrasion, leaks, or wear on the hydraulic lines. Research indicates that neglecting minor issues like these can lead to major failures, with operational downtime costing companies thousands of dollars per hour.

Following visual checks, measuring the piston's dimensions using calipers is essential. This helps in detecting erosion or deformation that could compromise functionality. According to industry data, even a slight mismatch in dimensions can lead to a 20-30% decrease in performance efficiency. Additionally, analyzing the hydraulic fluid's condition is vital; polluted fluid can deteriorate system components and cause significant malfunctions. By regularly monitoring these aspects, one can prevent costly repairs and extend the lifespan of hydraulic systems, thereby maintaining productivity in various sectors like agriculture and transportation.

10 Best Tips for Effective Hydraulic Piston Repair Techniques

| Tip Number | Tip Description | Step-by-Step Technique |

|---|---|---|

| 1 | Visual Inspection | Look for visible damages, corrosion, or leaks. |

| 2 | Check Seals | Inspect O-rings and seals for wear and tear. |

| 3 | Measure Cylinder Bore | Use a micrometer to determine the bore diameter. |

| 4 | Check Piston Rod | Inspect for scoring, bending, or pitting. |

| 5 | Clean Components | Use a suitable solvent to clean all components. |

| 6 | Inspect for Wear | Check components like rings and bushings for wear. |

| 7 | Lubricate Parts | Apply appropriate lubricants to moving parts. |

| 8 | Reassemble Carefully | Follow proper assembly procedures to avoid mistakes. |

| 9 | Test Functionality | Conduct a pressure test to ensure proper operation. |

| 10 | Document the Repair | Record details of the repair for future reference. |

Best Practices for Maintaining Hydraulic Piston Performance Post-Repair

Maintaining hydraulic piston performance after repair is crucial for ensuring optimal functionality and longevity. One of the best practices is to establish a regular maintenance schedule that includes thorough inspections. These inspections should focus on detecting signs of wear and tear, leakage, or contamination that could compromise the hydraulic system. By addressing these issues promptly, you can prevent more significant problems that may arise from neglect.

Additionally, using high-quality lubricants and seals is essential for sustaining performance. The right materials can minimize friction and wear, extending the lifespan of the hydraulic piston. Proper assembly techniques during the repair process also play a significant role; ensuring that all components are aligned and fitted correctly reduces the risk of failure. Educating operators about the signs of potential issues and encouraging them to report anomalies can further aid in maintaining hydraulic piston efficiency long after the repair has been completed.

Related Posts

-

7 Compelling Reasons to Invest in Hydraulic Pumps for Your Business Needs

-

Essential Checklist for Choosing the Best Hydraulic Parts for Your Industrial Needs

-

Innovative Solutions for Optimal Hydraulic Performance

-

How to Maximize the Lifespan of Your Cylinder with Effective Repair Techniques

-

Exploring the Unique Features and Applications of Various Hydraulic Valve Types

-

Fluid Power Hydraulics vs Pneumatics Key Insights for Global Buyers

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com