Why Choose a Metallurgical Bridge Crane for Your Facility?

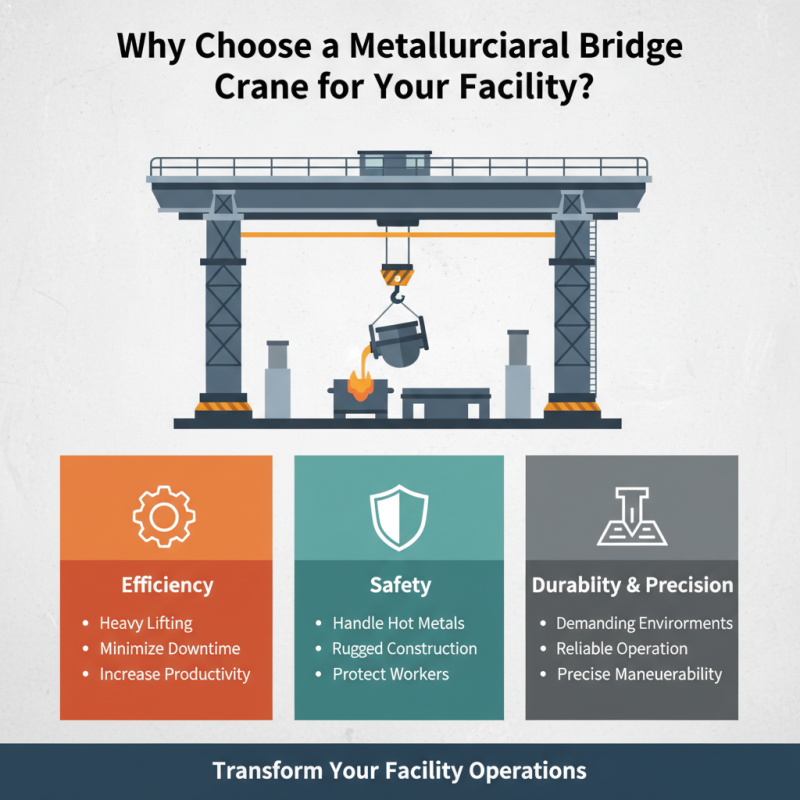

In today's industrial landscape, efficiency and safety are paramount. The selection of the right equipment significantly impacts operations. A Metallurgical Bridge Crane stands out as an ideal choice for heavy lifting tasks. This specialized crane is designed for performance in demanding environments, such as steel mills and foundries.

Metallurgical Bridge Cranes excel at handling hot metals and heavy materials. They often feature rugged construction and precise maneuverability. These cranes are essential for minimizing downtime in production processes. Their ability to withstand harsh conditions makes them a reliable option. However, purchasing such equipment requires careful consideration.

Facilities must assess their unique operational needs. Choosing a Metallurgical Bridge Crane is not just about lifting capacity. It's also about ensuring worker safety and maximizing efficiency. Investing in the right crane can dramatically enhance productivity. Organizations can sometimes underestimate the long-term benefits of this decision. The choice of a Metallurgical Bridge Crane can lead to a transformative impact on facility operations.

Understanding Metallurgical Bridge Cranes and Their Applications

Metallurgical bridge cranes are essential for metalworking facilities. They are designed to handle heavy loads and operate in demanding environments. These cranes play a vital role in transporting molten metal, steel plates, and heavy machinery. Their robust design ensures safety and efficiency.

Some tips for choosing the right metallurgical bridge crane include assessing your facility's layout. Consider the weight capacity you need. Each operation has its specific requirements. A crane that is too small may lead to operational issues. On the other hand, an oversized crane can cause unnecessary costs.

Understanding your crane's application is crucial. Different jobs demand different features. Some cranes are ideal for high-temperature environments, while others may be better for heavy-duty lifting. Regular inspections and maintenance are also key to ensuring reliable performance. If your crane experiences breakdowns frequently, it might indicate design or usage issues. Reflecting on these aspects can lead to better operational decisions.

Key Advantages of Utilizing Metallurgical Bridge Cranes in Facilities

Metallurgical bridge cranes offer significant advantages for industrial facilities. Their design allows for efficient handling of heavy materials often found in metalworking environments. These cranes can lift loads that are thousands of pounds. This capability minimizes manual labor and reduces the risk of injury on the shop floor.

One key benefit is their flexibility. Metallurgical bridge cranes can be customized to fit various facility layouts. They can navigate complex environments with tight spaces. Their ability to move in multiple directions enhances workflow efficiency. However, these cranes require regular maintenance to ensure optimal performance. Over time, wear and tear can lead to issues. It's vital to monitor their condition closely.

Additionally, metallurgical bridge cranes contribute to safety. By mechanizing the lifting process, they reduce human error. Workers can focus on other important tasks, increasing productivity. Yet, operator training is essential. Poorly trained staff can lead to accidents. Facilities must invest in proper operation practices to fully utilize the benefits of these cranes.

Considerations for Selecting the Right Metallurgical Bridge Crane

When selecting a metallurgical bridge crane, several key factors deserve attention. These cranes operate in high-intensity environments. They often handle molten metals and heavy equipment. According to the International Journal of Industrial Crane Engineering, the right crane can enhance safety and efficiency by up to 30%. Choosing a crane with appropriate load capacity is crucial.

Load capacity isn't everything, though. Consider the materials used in construction. Steel quality impacts durability and performance. The American Society of Mechanical Engineers (ASME) emphasizes the importance of compliance with safety standards. Incorrectly specified materials can lead to equipment failures. Those failures might result in costly downtimes and accidents.

Control systems and ease of use are also vital. Advanced control systems improve precision in operations. Natural user interfaces help in training operators quickly. Yet, sometimes these systems can complicate operations. Continuous evaluation and training are essential. Facilities must reassess their crane choice periodically. Needs may shift as production demands change. Taking these aspects into account can lead to better decision-making.

Why Choose a Metallurgical Bridge Crane for Your Facility?

Considerations for Selecting the Right Metallurgical Bridge Crane

| Criteria | Description | Importance |

|---|---|---|

| Load Capacity | The maximum weight the crane can lift. | Critical for safety and operational efficiency. |

| Span Length | The distance between the crane's support structures. | Affects coverage area and flexibility. |

| Height of Lift | The maximum height to which the crane can lift loads. | Necessary for operations with varying elevation needs. |

| Duty Cycle | Frequency of use and load handling over time. | Determines the crane’s durability and lifespan. |

| Environment | Conditions like temperature, humidity, and potential corrosive elements. | Influences choice of materials and design. |

| Control Systems | Type of controls such as manual, radio, or automated. | Affects ease of operation and safety features. |

Maintenance Practices for Optimal Performance of Bridge Cranes

Maintaining a metallurgical bridge crane requires consistent effort. Regular inspections are crucial. Check all components for wear and tear. Look for signs of rust or damage. Ignoring these details can lead to costly failures.

Proper lubrication is essential. Use the right type of oil for joints and gears. Schedule routine lubrication sessions. A squeaky crane often indicates it needs attention. Don't overlook any unusual noises; they are red flags.

Training staff on safe operation also matters. Provide ongoing education about best practices. Encourage workers to report issues promptly. A culture of awareness helps prevent accidents. Focus on proactive measures instead of reactive fixes. This approach creates a safer, more efficient work environment.

Safety Protocols and Standards for Metallurgical Bridge Crane Operations

Safety is paramount in metallurgical bridge crane operations. According to the Occupational Safety and Health Administration (OSHA), over 10,000 accidents occur annually in crane-related operations. This statistic underscores the need for stringent safety protocols. Proper training and operational standards can dramatically reduce these incidents. Regular audits should assess compliance with safety measures and identify potential hazards.

Workers must be aware of their environment. Visual indicators and signage should be visible throughout the facility. This helps maintain safety awareness. Implementing a buddy system can enhance vigilance among crew members. Personal protective equipment (PPE) should be a priority. The American National Standards Institute (ANSI) reports that proper PPE usage can decrease injury rates significantly. However, many facilities struggle with enforcing consistent PPE protocols.

The design of metallurgical bridge cranes should facilitate safety. Features like emergency stop buttons and overload indicators are critical. Yet, many facilities overlook these aspects during installation. Continuous training programs can improve response times in emergencies. But monitoring adherence to training is often inadequate. Equipping operators with the right knowledge will minimize risks. Increasing awareness of these protocols can lead to safer operational environments.

Article Source:

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com