Finding the Right Manufacturer for Quality Hydraulic Pumps

In the dynamic landscape of manufacturing, selecting the right manufacturer for hydraulic pumps is critical for ensuring operational efficiency and product reliability. According to a report by Industry Research, the global hydraulic pumps market was valued at approximately $13.4 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 5.3% through 2027. This growth is driven by the increasing demand for hydraulic systems across various sectors, including construction, agriculture, and manufacturing. As industries continue to expand, the significance of choosing a manufacturer who prioritizes quality becomes paramount.

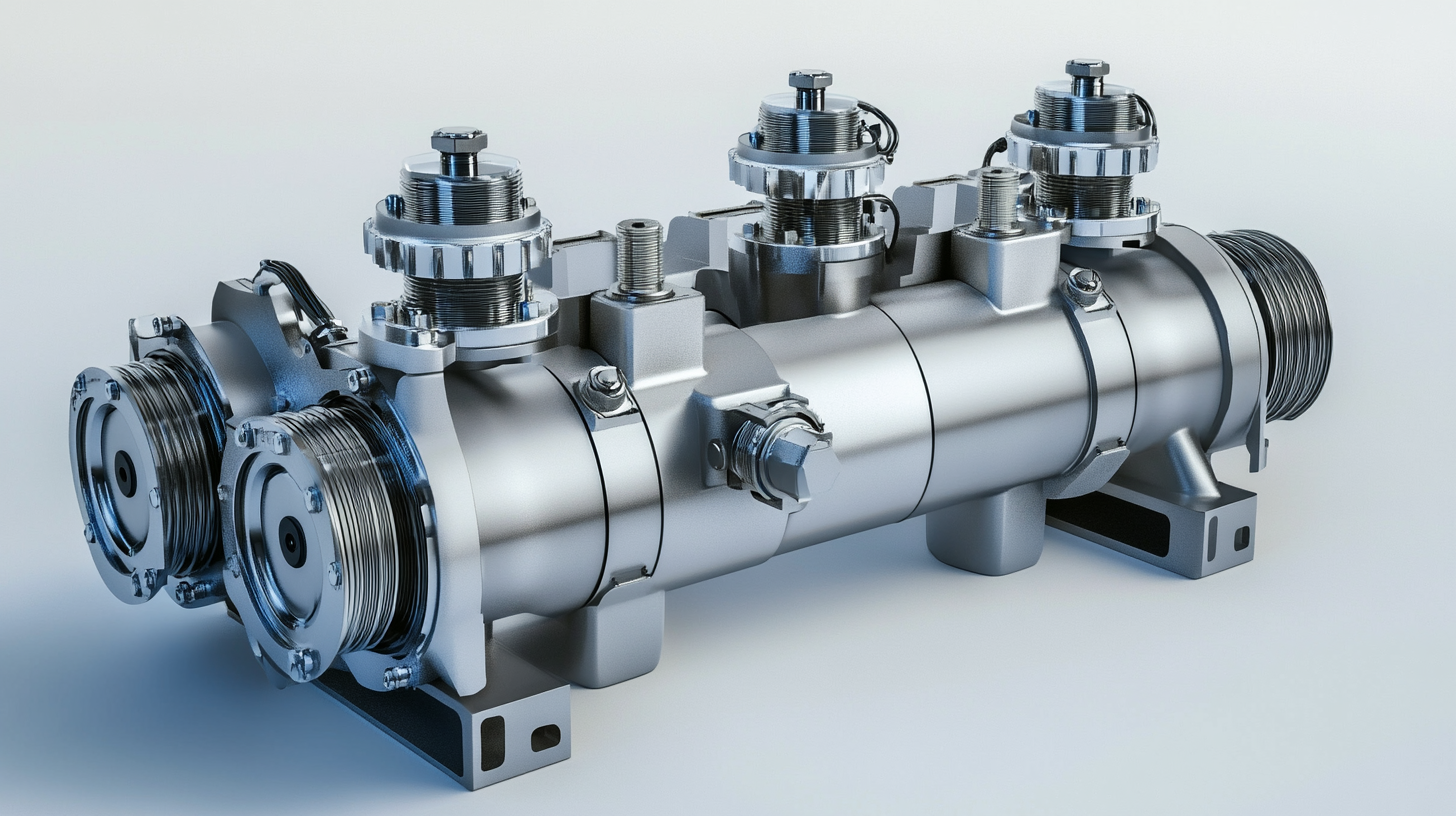

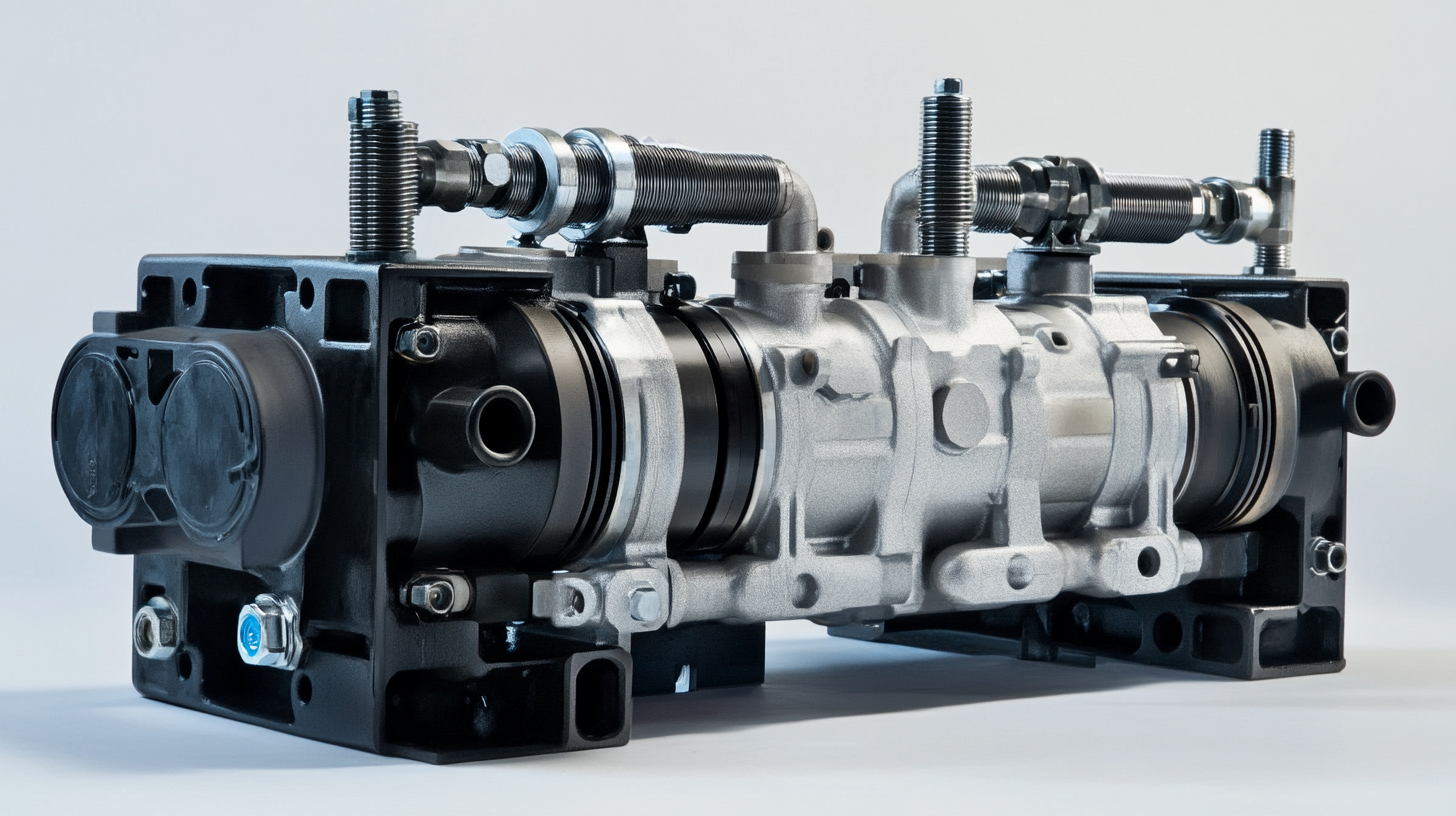

Hydraulic pumps play an essential role in numerous applications, serving as the heart of hydraulic systems by converting mechanical energy into hydraulic energy. However, not all hydraulic pumps are created equal, and the right choice can significantly impact performance, durability, and maintenance costs. A study from the Hydraulic Institute indicates that over 30% of system failures can be traced back to poor pump selection or manufacturing defects. Therefore, it is vital for businesses to leverage both industry insights and reputable data when seeking a manufacturer that guarantees high standards of quality, thereby protecting their investment and ensuring seamless operations.

Identifying Key Factors for Choosing a Hydraulic Pump Manufacturer

When selecting a manufacturer for hydraulic pumps, it is crucial to consider several key factors that influence both product quality and performance. Firstly, evaluating the manufacturer’s reputation within the industry is essential. Look for companies that have a proven track record of producing reliable hydraulic pumps. Customer testimonials, industry certifications, and case studies can provide valuable insights into their manufacturing processes and product offerings. Another important aspect to consider is the level of customization available. Different applications require different specifications, so a manufacturer that offers tailored solutions can greatly enhance system efficiency. Inquire about their capabilities in producing custom-engineered hydraulic pumps and whether they can adapt to specific requirements. Furthermore, assess their research and development practices; a commitment to innovation often indicates a manufacturer that prioritizes quality and performance, ensuring their products can meet evolving industry standards. Finally, after-sales support plays a critical role in your decision-making process. A reliable manufacturer should provide strong technical support, maintenance services, and readily available spare parts. A manufacturer that stands behind their products with excellent customer service will not only improve your operational efficiency but also provide peace of mind. By focusing on these factors—reputation, customization, and support—you can find the right hydraulic pump manufacturer that aligns with your needs.

Evaluating Manufacturer Reputation and Experience in the Industry

When seeking the right manufacturer for quality hydraulic pumps, evaluating the manufacturer's reputation and experience in the industry is crucial. According to a report by ResearchAndMarkets, the global hydraulic pump market was valued at approximately $15 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2027. This underscores the increasing demand for reliable hydraulic systems across various sectors, emphasizing the need for reputable manufacturers.

One effective approach to assess a manufacturer’s reputation is to analyze their track record and longevity in the industry. Manufacturers with over 20 years of experience often have established relationships with suppliers and a deep understanding of industry standards. For instance, businesses such as Bosch Rexroth and Parker Hannifin, which have been leaders for decades, benefit from their extensive experience and reliability. The American Society of Mechanical Engineers (ASME) highlights that over 70% of companies favor manufacturers with proven success, as it reduces the risk associated with production inefficiencies and product failure.

Additionally, customer testimonials and case studies can provide insights into a manufacturer’s performance and quality assurance processes. A survey conducted by Market Research Future found that 64% of companies prioritize quality control measures when choosing a hydraulic pump supplier. Manufacturers who invest in ISO certification and follow rigorous quality standards showcase their commitment to excellence, further enhancing their credibility in the market.

In conclusion, careful evaluation of a manufacturer's reputation and experience can lead to more informed decisions in sourcing hydraulic pumps, ultimately ensuring a reliable and efficient operation.

Understanding Quality Control Standards for Hydraulic Pump Production

When selecting a manufacturer for hydraulic pumps, understanding quality control standards is paramount. These standards ensure that the pumps not only meet industry specifications but also perform reliably under various operating conditions. Recently, advancements in hydraulic technology, such as proprietary tooth geometry in gear pumps, have significantly improved performance by reducing noise levels. This innovation highlights the importance of quality control in design and production, as it directly enhances user experience and satisfaction.

Moreover, modern manufacturing techniques, including metal 3D printing and sensor integration, are revolutionizing hydraulic pump production. These technologies allow for greater precision and customization, which can lead to more efficient and durable products. As the industry evolves, manufacturers must prioritize robust testing and validation processes to uphold quality standards. Physical testing remains essential, providing real-world data that informs better design and manufacturing practices, ensuring that pumps can withstand demanding operational environments.

As electric vehicles rise in prominence, the continued development of hydraulic systems, including enhanced ePTOs, signifies the ongoing need for quality assurance in hydraulic technology. Manufacturers must adapt to new regulations and standards, such as those concerning fluid power systems, to maintain compliance and ensure product safety. Emphasizing stringent quality control measures throughout the production process will enable manufacturers to produce reliable hydraulic pumps that meet the diverse demands of modern applications.

Exploring Customization Options and Technical Support Services

When looking for the right manufacturer for hydraulic pumps, it's essential to explore the customization options they offer. Different applications require specific features, such as varying pressure ratings, size configurations, and specialized materials. A manufacturer that provides customization can tailor the hydraulic pump to meet your unique needs, ensuring optimal performance and efficiency in your operations. This adaptability not only enhances functionality but can also lead to significant cost savings in the long run.

In addition to customization, robust technical support services are vital when selecting a manufacturer. With the advancement of technology, many companies are now integrating AI chatbots to improve their customer service. These chatbots can provide immediate assistance for technical inquiries, troubleshoot issues in real-time, and guide customers through the complexities of hydraulic pump systems without the need for human intervention. This level of support can be invaluable, especially when dealing with intricate hydraulic systems where prompt resolution of issues is crucial.

Furthermore, a manufacturer with strong technical support services can assist in the training and onboarding of your team, ensuring they understand how to operate and maintain the hydraulic pumps effectively. This focus on customer satisfaction and support can significantly enhance your operational efficiency, providing peace of mind as you navigate the challenges of your industry. Ultimately, choosing a manufacturer that prioritizes customization and technical support leads to better outcomes for your projects and long-term partnership success.

Assessing Cost-Effectiveness Without Compromising Quality

In the pursuit of high-quality hydraulic pumps, manufacturers often face the challenging task of balancing cost-effectiveness with uncompromised performance. Recent research has demonstrated that companies can achieve significant cost savings by leveraging digital health interventions. According to a systematic review published in 2023, implementing these advanced technologies has shown a potential reduction in operational costs by as much as 30%. For manufacturers in the hydraulic pump sector, this insight is critical; it underscores the importance of integrating modern technologies to streamline production processes while maintaining product quality.

Cost-effectiveness does not solely hinge on price; it encompasses the entire lifecycle of the product. A report by the Hydraulic Institute indicates that selecting the right manufacturer can yield a return on investment (ROI) exceeding 180% over five years, emphasizing the long-term benefits of quality over initial costs. To maximize this ROI, manufacturers must conduct thorough assessments of potential suppliers, focusing on their technological capabilities, customer service history, and quality assurance practices.

Furthermore, understanding market trends is essential. The PMMI Business Intelligence study revealed that 70% of industry leaders plan to invest in smarter solutions to enhance production efficiency. By prioritizing quality manufacturers equipped with advanced capabilities, companies can achieve a harmonious balance between cost-effectiveness and product integrity, ultimately leading to a more sustainable growth trajectory in the competitive hydraulic pump market.

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com