How to Choose the Right Rubber Pump Impeller for Your Needs?

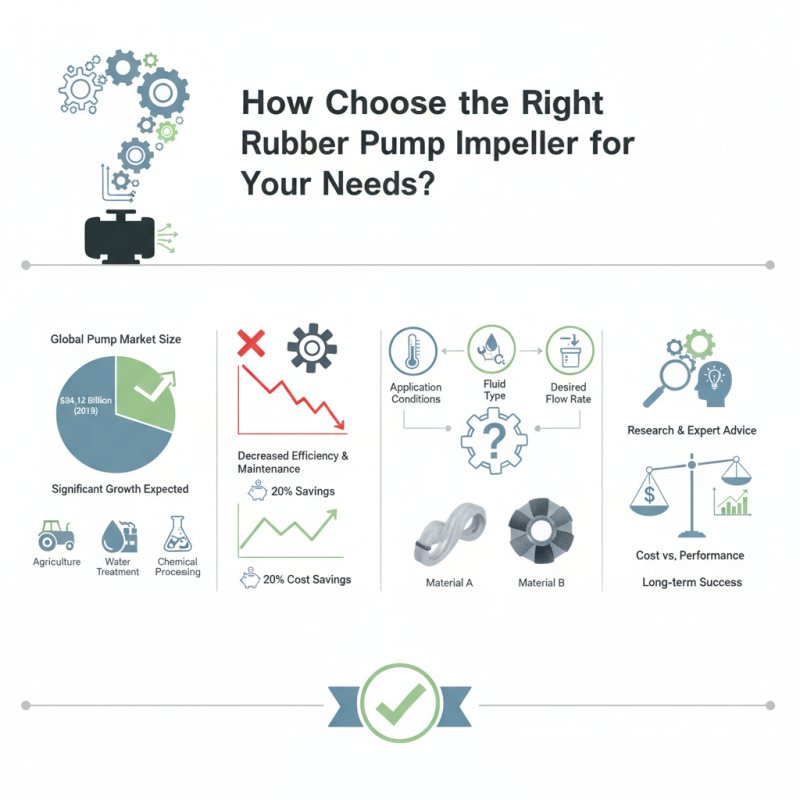

Choosing the right Rubber Pump Impeller is crucial for efficiency. The global pump market size was valued at $34.12 billion in 2019 and is expected to grow significantly. Rubber impellers play a vital role in various industries, including agriculture, water treatment, and chemical processing. Their flexibility and resistance to wear make them essential for optimal pump performance.

However, selecting the right impeller can be daunting. Many factors influence this choice. The application conditions, fluid type, and desired flow rate must all be considered. Data suggests that improper selection can lead to decreased efficiency and increased maintenance costs. According to industry reports, up to 20% cost savings can be achieved by using the correct Rubber Pump Impeller.

It is essential to reflect on the unique requirements of your application. Not all rubber impellers are created equal. Differences in materials and designs can lead to varying performance outcomes. It is worth investing time in research and seeking expert advice to avoid costly mistakes down the line. Balancing between cost and performance remains a challenge. Choose wisely for long-term success.

Understanding the Role of Rubber Pump Impellers in Fluid Dynamics

Rubber pump impellers play a crucial role in fluid dynamics. They are responsible for the movement of liquids within various systems. When designed effectively, they enhance the operational efficiency of pumps. The shape and material of the impeller significantly influence how fluids flow. An impeller that excels in one application may underperform in another. This presents a challenge for users.

Understanding the fluid being pumped is essential. Different fluids possess unique properties. Viscosity, temperature, and chemical composition matter greatly. For instance, pumping thick liquids requires a different impeller design than pumping water. Users might overlook these details, leading to poor performance. It’s essential to evaluate the operating conditions.

While rubber impellers are versatile, they have limitations. They are not ideal for extremely high temperatures or abrasive substances. Users should also consider wear and tear over time. There can be instances where the chosen impeller doesn’t fit perfectly. This misalignment can lead to inefficiency or damage. Reflecting on past mistakes can guide better choices in the future. Understanding these factors can result in a more efficient pumping system.

How to Choose the Right Rubber Pump Impeller for Your Needs?

| Impeller Type | Applications | Material Characteristics | Efficiency Rating | Cost Range (USD) |

|---|---|---|---|---|

| Open Impeller | Water Transfer, Wastewater Treatment | High solids handling, lower clogging risk | 80-85% | $150 - $300 |

| Closed Impeller | High Pressure Systems, Industrial Applications | Higher efficiency, suitable for clear fluids | 85-90% | $200 - $400 |

| Semi-Open Impeller | Pulp and Paper, Chemical Processing | Balance between efficiency and solids handling | 75-80% | $175 - $350 |

| Vortex Impeller | Sludge and Heavy Slurry Handling | Designed for chunky or abrasive materials | 70-75% | $120 - $250 |

| Channel Impeller | Irrigation Systems, HVAC | Efficient for transporting large volumes of water | 78-82% | $160 - $320 |

Key Factors to Consider When Selecting a Rubber Pump Impeller

Choosing the right rubber pump impeller involves several key factors. Material composition is crucial. Different types of rubber offer various levels of resistance to heat, wear, and harsh chemicals. You must evaluate the environmental conditions your pump will operate in. Failing to account for these elements may lead to premature wear or failure.

Another important aspect is the impeller design. It’s essential to ensure that the impeller fits your specific pump model. An ill-fitting impeller can reduce efficiency and cause cavitation issues. Consider the flow rate requirements too. An impeller that does not match the flow demands can compromise performance.

The size of the impeller is often overlooked. A larger impeller may increase flow, but it also requires more energy. Conversely, a smaller impeller could reduce performance. Balancing size, energy consumption, and flow is tricky. It's easy to make mistakes here. Regular maintenance should not be ignored. Regular checks can help prevent unexpected failures and prolong the impeller's lifespan. Being attentive to these details can save time and resources.

Types of Rubber Materials Used in Pump Impeller Manufacturing

When selecting a rubber pump impeller, the choice of materials plays a crucial role. Various types of rubber materials are utilized in manufacturing these impellers. Common options include natural rubber, neoprene, and EPDM. Each material offers distinct properties suitable for different applications. For instance, natural rubber is known for its excellent tensile strength and abrasion resistance. However, it may not perform well in extreme temperatures.

Neoprene impellers are versatile and can withstand oils and chemicals, making them ideal for various industrial needs. Meanwhile, EPDM offers great resistance to heat, ozone, and weathering. According to a 2022 industry report, over 45% of pump manufacturers prefer neoprene for its adaptability. Despite these benefits, specific conditions may lead to degradation over time.

Choosing the right material can be challenging. Some users overlook the importance of compatibility with the fluids being pumped. Testing each material in realistic conditions is crucial. A study highlighted that improper selection could lead to a 30% reduction in pump efficiency. Understanding the properties of rubber materials can help in making informed choices.

Sizing and Compatibility: Ensuring Your Impeller Fits Your Pump System

Choosing the correct rubber pump impeller is crucial for optimal performance. Sizing and compatibility are key factors in this decision. Impellers must fit your specific pump model. This ensures they function efficiently under varying operational conditions. Measure your pump's diameter and ensure the impeller matches these dimensions closely.

Compatibility also extends beyond size. Material type is another consideration. Rubber impellers come in different compounds. Each type offers unique resistance to wear and chemical exposure. Understand the fluid you will be pumping. Not all rubber is equal in this regard. Some fluids can degrade certain materials quickly, leading to failures.

Evaluate the specific application as well. High-pressure systems may require different designs compared to low-flow systems. Examine flow rates and pressure ratings. It's easy to overlook this, but it’s vital. Make adjustments where necessary. Testing the fit once installed is wise. An ill-fitting impeller can cause inefficiencies and unexpected damage. Regular maintenance check-ups can help identify any issues before they escalate.

Maintenance and Longevity: Choosing Durable Rubber Impellers for Efficiency

Choosing the right rubber pump impeller can significantly influence your system's efficiency. The durability of the impeller is crucial for maintenance and longevity. A well-constructed rubber impeller can withstand harsh conditions, ensuring a reliable operation over time. When selecting an impeller, consider the material composition. Some rubbers perform better under specific temperatures or corrosive environments.

Tips: Always check the wear and tear on your impellers regularly. Signs of damage can lead to bigger problems later. Don't overlook minor cracks; they could signal a need for replacement.

Additionally, think about the operational environment. High levels of debris in liquids can impact impeller performance. Choosing an impeller designed for such conditions may prevent premature failure. However, it would be good to remember that no impeller lasts forever.

Tips: Keep spare impellers on hand. This approach can minimize downtime during unexpected failures. Reflect on your maintenance schedule. Adjustments may be necessary as equipment ages.

Article Source:

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com