How to Choose the Right Ball Bearing for Your Project?

Choosing the right Ball Bearing for your project can be daunting. According to Dr. Emily Carter, a leading expert in the ball bearing industry, "Selecting the right ball bearing is crucial for performance." This statement emphasizes the importance of making informed choices.

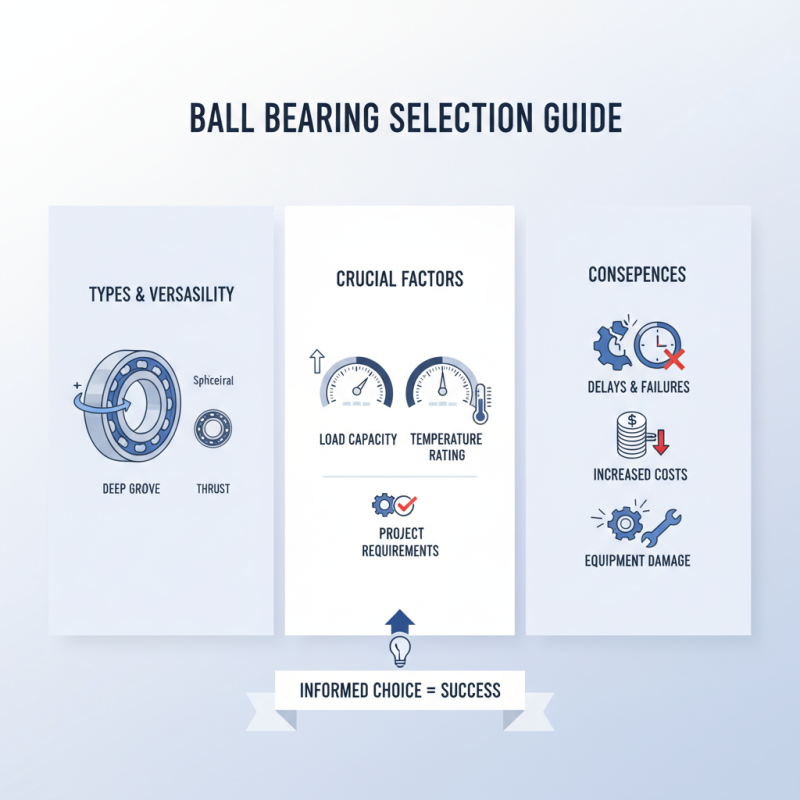

Ball bearings come in various types and sizes. Each type serves a different purpose and affects performance. For instance, deep groove ball bearings are commonly used for their versatility. However, not every project requires this type. Many overlook specific load capacities or temperature ratings. These factors can lead to failures.

The consequences of choosing the wrong ball bearing can be significant. Projects may face delays, increased costs, or even equipment damage. Many engineers have faced regrets when they realize they didn't evaluate all options. Understanding the nuances in ball bearings is essential for success.

Understanding the Basics of Ball Bearings and Their Applications

Ball bearings are critical components in many mechanical systems. They reduce friction and enhance efficiency. Understanding their types can guide your selection process. In 2022, the global ball bearing market reached approximately $30 billion, with a compound annual growth rate (CAGR) of 6.5% forecasted through 2027. This growth highlights their importance in industries like automotive and aerospace.

Different applications require specific bearing designs. Standard deep groove ball bearings are versatile, but not always ideal. For high-load applications, tapered roller bearings are more effective. Often, projects overlook lubrication needs. Proper lubrication significantly impacts bearing life. Up to 70% of bearing failures stem from inadequate lubrication, according to industry reports.

In high-speed applications, ceramic ball bearings are becoming popular, due to their lower density and resistance to wear. However, they might not suit all environments. Cost can also be a limiting factor. Balancing performance and budget is essential. Many projects can benefit from hybrid bearings, combining steel and ceramic materials. Yet, engineers must analyze environmental conditions before making a choice.

Identifying Key Specifications for Selecting Ball Bearings

Choosing the right ball bearing starts with understanding key specifications. One essential factor is the bearing's load capacity. This determines how much weight the bearing can handle without failure. Check the dynamic and static load ratings.

Another important specification is the bearing size. It should fit well within your design. Measure the inner and outer diameters accurately. Additionally, consider the width of the bearing. A tighter fit can lead to better performance.

**Tips:** Always account for operating conditions. Temperature and humidity can affect bearing life. Selecting the wrong type can lead to premature wear. Inspect your design frequently for unexpected issues.

Material is also critical. Steel bearings are common but might rust. Stainless steel or ceramic options exist. They can offer better corrosion resistance. Reflect on long-term durability when choosing materials. The choice should align with your specific project needs.

Ball Bearing Specifications Comparison

This chart compares various key specifications for three different types of ball bearings. It highlights important factors such as load capacity, speed rating, dirt resistance, material quality, and cost, helping you make an informed decision for your project.

Evaluating Load Capacity and Factor Considerations

Choosing the right ball bearing for your project involves understanding load capacity. This capacity dictates how much weight the bearing can support without failing. Each application has its unique demands. Knowing these demands is crucial.

Different factors affect load capacity. Dynamic load ratings are essential for moving applications. Use static load ratings for stationary setups. You must consider the speed as well. Faster speeds can lead to increased heat, affecting performance. Pay attention to maintenance needs, too. A neglected bearing might not perform as expected.

Don't underestimate environmental conditions. Temperature, moisture, and dust can impact longevity. Test your selection under actual conditions when possible. This process can be lengthy and might reveal weaknesses in your choice. Adjustments may be necessary after initial testing. Be prepared to reflect and adapt your selection. The right choice can lead to efficiency and reliability in your project.

How to Choose the Right Ball Bearing for Your Project? - Evaluating Load Capacity and Factor Considerations

| Bearing Type | Load Capacity (N) | Speed Rating (RPM) | Noise Level (dB) | Material |

|---|---|---|---|---|

| Deep Groove Ball Bearing | 5000 | 3000 | 30 | Chrome Steel |

| Angular Contact Ball Bearing | 7500 | 2500 | 35 | Stainless Steel |

| Self-Aligning Ball Bearing | 4000 | 2000 | 40 | Brass |

| Thrust Ball Bearing | 3000 | 1500 | 42 | Ceramic |

| Spherical Roller Bearing | 10000 | 1800 | 38 | Alloy Steel |

Assessing Environmental Factors and Material Compatibility

When choosing a ball bearing, considering environmental factors is crucial. These factors can significantly affect performance and longevity. For instance, if your project operates in a humid environment, you might need bearings that resist corrosion. Materials like stainless steel or ceramic can offer better protection against rust. However, the cost may be higher.

Material compatibility is equally important. Different materials interact in ways that can lead to premature failure. For example, pairing plastic components with metal bearings can cause wear over time. It’s useful to consult charts or guidelines for material compatibility. Not all combinations yield the intended results, and experimenting without careful thought can lead to unexpected issues.

You might find that your initial choice isn’t perfect. It can be a challenge to balance performance, cost, and environmental needs. Ask yourself: Is the bearing resilient enough? Will it withstand the conditions of your project? Keep testing, and be open to adjustments. The goal is not just to select a bearing but to ensure long-term success in your application.

Comparing Different Types of Ball Bearings for Project Needs

When selecting the right ball bearing for your project, understanding the different types available is crucial. Ball bearings can be categorized into several types: deep groove, angular contact, and thrust bearings, among others. Each type serves distinct purposes based on load requirements, speed, and precision. For example, deep groove ball bearings are versatile and widely used in various applications, handling both radial and axial loads effectively.

A recent industry report states that ball bearing demand is projected to grow at a rate of 5.6% annually. This growth emphasizes the need for careful selection. The load capacity varies significantly between types. For instance, angular contact bearings can support higher axial loads compared to deep groove models. However, they may not be as efficient in low-load situations. This trade-off impacts performance, and understanding your specific needs is key.

Some designers overlook lubrication requirements. Proper lubrication enhances bearing life. Yet, many users skip this step, leading to premature failure. Acknowledging these details is essential for maximizing efficiency. It’s important to weigh the benefits of each bearing type against the demands of your project. This approach ensures optimal performance and longer service life.

Article Source:

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com