Understanding the Common Issues Faced by Hydraulic Pumps in Industrial Applications

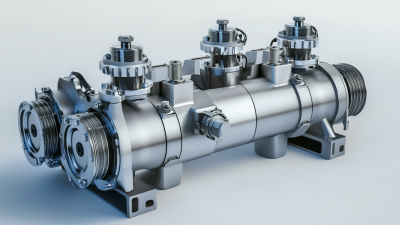

Hydraulic pumps play a critical role in various industrial applications, powering machines and systems that require reliable energy transfer. According to a report by the International Fluid Power Society, hydraulic systems account for approximately 25% of the total energy consumption in industrial settings, underscoring the importance of efficient and robust hydraulic pump performance.

Despite their significance, these pumps often face common issues such as cavitation, contamination, and improper maintenance, which can lead to decreased efficiency and costly downtimes. Industry statistics reveal that nearly 70% of hydraulic pump failures are attributed to operational errors and maintenance neglect. Understanding these challenges is vital for industries to enhance pump reliability and ensure optimal performance, ultimately contributing to the efficiency and profitability of their operations.

Common Causes of Hydraulic Pump Failures in Industrial Settings

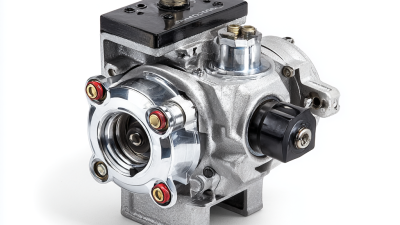

Hydraulic pumps are critical components in various industrial applications, yet they often encounter issues that can lead to operational failures. Understanding the common causes of hydraulic pump failures is essential for maintaining efficiency and preventing costly downtime. One of the primary reasons for pump failure is contamination within the hydraulic fluid. Particles, water, or chemical residues can hinder the pump's performance, leading to wear and tear and ultimately, malfunction.

Another frequent cause of hydraulic pump issues is inadequate maintenance. Regular checks and servicing are crucial to ensure that components function correctly and efficiently. Neglecting to change filters, monitor fluid levels, and inspect for leaks can result in excessive stress on the pump, causing it to fail prematurely. Additionally, improper sizing of the hydraulic system can also lead to performance problems, as pumps may not be able to generate the required pressure or flow rate if they are undersized or oversized. Addressing these common problems through vigilant maintenance and proper system design can significantly enhance the longevity of hydraulic pumps in industrial settings.

Effective Diagnostic Techniques for Identifying Hydraulic Pump Issues

Hydraulic pumps are essential components in various industrial applications, but they can encounter a range of issues that affect their efficiency and performance. Identifying these problems early is crucial to maintaining operational integrity. Effective diagnostic techniques can help pinpoint the source of hydraulic pump malfunctions and streamline the troubleshooting process.

One of the most effective ways to diagnose hydraulic pump issues is through regular monitoring of system pressure and flow rates. A significant drop in either of these metrics often indicates potential blockages or wear in the pump components. Additionally, monitoring the hydraulic fluid temperature can reveal overheating issues, which may suggest inadequate cooling or excessive workload on the pump.

Tip: Always check for unusual noises coming from the hydraulic pump. Grinding or rumbling sounds may be indicative of internal damage or cavitation, which can lead to severe failures if not addressed promptly.

Another diagnostic technique is to inspect the hydraulic fluid for contamination. Regularly sampling the fluid and analyzing it for particulates or moisture can provide insights into the pump's condition. Clean hydraulic fluid is vital for optimal performance and longevity.

Tip: Implement a scheduled maintenance routine to replace filters and manage fluid quality. This proactive approach can greatly reduce the chances of unexpected pump failures.

Preventive Maintenance Strategies to Extend Hydraulic Pump Lifespan

Preventive maintenance plays a crucial role in extending the lifespan of hydraulic pumps, essential in various industrial applications. According to a report from the Hydraulic Institute, improper maintenance can shorten a pump's lifespan by up to 50%, leading to unplanned downtimes and significant repair costs. Regular maintenance activities, such as inspection and service schedules, should be implemented to identify potential issues before they escalate. Key practices include monitoring fluid levels, checking for leaks, and ensuring that filters are clean, all of which can dramatically improve operational efficiency and reduce equipment failures.

Additionally, the American Society of Mechanical Engineers (ASME) highlights that up to 80% of hydraulic system failures are attributed to improper fluid quality and temperature control. By regularly testing hydraulic fluids for contaminants and maintaining the recommended temperature range, operators can avoid damaging the pump's internal components. Implementing a comprehensive preventive maintenance strategy not only enhances the reliability of hydraulic pumps but also fosters a culture of safety and efficiency within industrial settings, ultimately leading to increased productivity and reduced lifecycle costs.

Innovative Solutions to Common Hydraulic Pump Performance Problems

Hydraulic pumps are crucial for various industrial applications, yet they often face performance problems that can impede operational efficiency. Common issues include poor fluid quality, cavitation, and inadequate maintenance practices. According to a report from the Hydraulic Institute, nearly 70% of hydraulic system failures are attributed to pump-related problems, underscoring the importance of addressing these issues proactively.

To tackle these performance challenges, innovative solutions have emerged. Implementing advanced filtration systems can significantly enhance fluid quality, reducing the risk of contamination-related failures. Additionally, utilizing variable frequency drives (VFDs) allows for precise control of pump speed, mitigating the effects of cavitation and improving overall system reliability. Regular maintenance schedules are also critical; as data from the International Fluid Power Society suggests, systems subjected to consistent maintenance see a 30% increase in operational lifespan.

Tips: Regularly check and replace filters to maintain optimal fluid quality. Consider investing in training for maintenance personnel to better identify and address common pump issues. Monitoring pump performance metrics can also help detect early signs of potential problems, allowing for timely interventions.

Upgrading Hydraulic Systems: When and Why to Consider Replacement

When it comes to upgrading hydraulic systems, the decision to replace hydraulic pumps often hinges on several critical factors. One of the primary reasons for considering replacement is efficiency. Over time, hydraulic pumps can experience wear and tear that leads to reduced performance, resulting in increased energy consumption and operating costs. If a pump is no longer able to perform at optimal levels, businesses may find that replacing it not only restores efficiency but also lowers overall operational expenses.

Another important reason to consider upgrading hydraulic systems is the advancement of technology. Modern hydraulic pumps come equipped with innovations that enhance reliability, decrease noise levels, and improve the control capabilities of hydraulic systems. For industries relying on precision and speed, upgrading to the latest models can significantly improve productivity and reduce downtime. Additionally, new pumps often offer better compatibility with eco-friendly fluids, which can help companies meet evolving environmental standards. Assessing the lifespan and technological status of current hydraulic pumps can guide businesses in making informed decisions about when and why to pursue replacements.

Understanding the Common Issues Faced by Hydraulic Pumps in Industrial Applications - Upgrading Hydraulic Systems: When and Why to Consider Replacement

| Issue | Description | Symptoms | Recommended Action | Replacement Indicator |

|---|---|---|---|---|

| Cavitation | Formation and collapse of vapor bubbles in the pump. | Unusual noise, vibration, and drop in performance. | Check for proper fluid levels and pressure. Maintain proper inlet conditions. | If persistent, consider redesigning the system or replacing the pump. |

| Overheating | Excessive heat generation in hydraulic fluid or components. | High fluid temperature, reduced efficiency, possible leakage. | Inspect cooling systems and check for fluid contamination. | If systems fail to cool properly, consider upgrading the pump. |

| Seal Leaks | Integrity loss of seals leading to fluid leakage. | Visible fluid leaks, reduced pressure, erratic operation. | Replace seals and check for damage to components. | If leaks continue, it may indicate deeper wear, necessitating replacement. |

| Contamination | Presence of particles or fluids that affect hydraulic performance. | Erratic operation, increased wear, overheating. | Implement better filtration and regular fluid changes. | If contamination is chronic, consider a system redesign. |

| Poor Performance | Pump not delivering the expected flow or pressure. | Sluggish operations, reduced output, increased cycle times. | Analyze system requirements and pump capabilities; recalibrate as necessary. | If pumps do not meet specifications consistently, consider replacement. |

Related Posts

-

Finding the Right Manufacturer for Quality Hydraulic Pumps

-

7 Compelling Reasons to Invest in Hydraulic Pumps for Your Business Needs

-

Ultimate Guide to Sourcing the Best Hydraulic Pumps for Your Business Needs

-

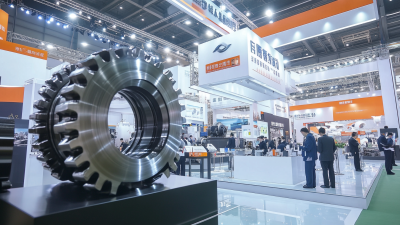

Exploring Global Opportunities for Hydraulic Gear Pumps at the Successful 137th Canton Fair

-

Future Trends and Market Insights for Best Hydraulic Pumps by 2025

-

Essential Checklist for Choosing the Right Hydraulic Piston Pump for Your Applications

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com