Discover Effective Strategies for Sourcing Quality Hydraulic Solutions Manufacturers

In today's fast-paced industrial landscape, sourcing quality hydraulic solutions is pivotal for ensuring operational efficiency and enhancing productivity. According to a report by Grand View Research, the global hydraulic equipment market is projected to reach USD 66.5 billion by 2025, driven by the increasing demand for energy-efficient systems across various sectors. As industries prioritize automation and machinery reliability, the need for reliable hydraulic solutions manufacturers has become more critical than ever. Understanding the nuances of sourcing such manufacturers can be the key to unlocking greater value in both production processes and overall business strategies.

However, sourcing quality hydraulic solutions is not merely about finding suppliers; it involves a comprehensive evaluation of their capabilities, product offerings, and technological advancements. A study published by MarketsandMarkets indicates that the hydraulic systems market is expected to witness a CAGR of 5.3% from 2020 to 2025, emphasizing the need for businesses to stay ahead in this dynamic environment. Companies that effectively navigate the complexities of supplier selection will not only bolster their supply chains but also enhance their competitive edge. This blog will explore effective strategies for sourcing quality hydraulic solutions manufacturers, enabling businesses to make informed decisions in a rapidly evolving market.

Identifying Key Industry Standards for Hydraulic Solutions Manufacturers

The hydraulic solutions manufacturing industry is witnessing significant growth, driven by rising demand across various sectors. According to a recent market report, the global hydraulic cylinders market was valued at approximately $14.07 billion in 2020, with projections estimating it to reach around $21.24 billion by 2030, representing a compound annual growth rate (CAGR) of 4%. This robust growth highlights the importance of sourcing quality manufacturers that adhere to key industry standards. Identifying key industry standards is crucial for ensuring that hydraulic solutions meet the necessary safety and performance benchmarks. The Hydraulic Institute, a leading authority in the field, emphasizes developing standards that accommodate emerging technology trends. These trends are reshaping engineering practices and influencing product innovation. For instance, the rising focus on environmental sustainability and efficiency is necessitating that manufacturers comply with new regulations and reporting requirements. Moreover, with industry leaders continuously expanding their operations, as evidenced by recent acquisitions, potential clients must assess the capabilities and certifications of manufacturers. A clear understanding of both regional and global standards not only fosters quality but also enhances competitiveness within the hydraulic equipment sector. Emphasizing these standards can lead to improved product reliability and performance, ultimately assisting companies in making informed sourcing decisions.

Evaluating Manufacturer Credentials and Certifications

When sourcing quality hydraulic solutions manufacturers, evaluating their credentials and certifications is a crucial step to ensure reliability and performance. First and foremost, it is essential to check if the manufacturer holds industry-specific certifications, such as ISO 9001, which signifies a commitment to quality management systems. A company that invests in obtaining these certifications not only demonstrates adherence to high operational standards but also assures potential clients that their products are produced with precision and care.

In addition to standard certifications, it’s important to look for specific endorsements related to hydraulic systems, such as those from the Hydraulic Institute or similar organizations. These endorsements can indicate that the manufacturer has undergone rigorous testing and conforms to industry best practices. Furthermore, researching customer reviews and case studies can provide insights into the manufacturer’s track record and reliability, which can be a telling factor of their competency in delivering high-quality hydraulic solutions.

Lastly, engaging with the manufacturer directly can further clarify their capabilities. Inquiring about their production processes, quality control measures, and after-sales support can give you a holistic view of their operational standards. A manufacturer that is transparent about their practices and is willing to provide detailed information can often be a reliable partner in your hydraulic solution needs.

Building Relationships with Preferred Hydraulic Suppliers

Building strong relationships with preferred hydraulic suppliers is crucial in today’s competitive market. As the manufacturing sector experiences growth, particularly with new commitments from international companies to open plants in the U.S., having reliable suppliers becomes even more pivotal. By fostering good relationships, industries can ensure a steady supply of high-quality hydraulic solutions that meet specific operational needs.

Engaging with suppliers on a personal level can lead to better communication and understanding of product specifications and requirements. Regular visits to supplier facilities, participation in joint training sessions, and open dialogues about product developments can enhance collaboration. It allows manufacturers to gain insights into supplier processes, capabilities, and innovations that could benefit their own production operations.

Furthermore, building these strategic partnerships enables manufacturers to navigate challenges more effectively. A trusted supplier can offer valuable support during unexpected shortages or price fluctuations, ensuring that production schedules remain uninterrupted. In an era where agility and responsiveness define success, nurturing these relationships with preferred hydraulic suppliers may prove to be a significant competitive advantage.

Utilizing Technology for Efficient Sourcing of Hydraulic Solutions

In today's rapidly evolving industrial landscape, leveraging technology for efficient sourcing of hydraulic solutions has become paramount. The integration of advanced technologies not only streamlines the procurement process but also enhances the overall quality of the hydraulic systems utilized across various sectors. Manufacturers can now harness data analytics and machine learning to effectively evaluate and select suppliers, ensuring they partner with those who adhere to stringent quality standards.

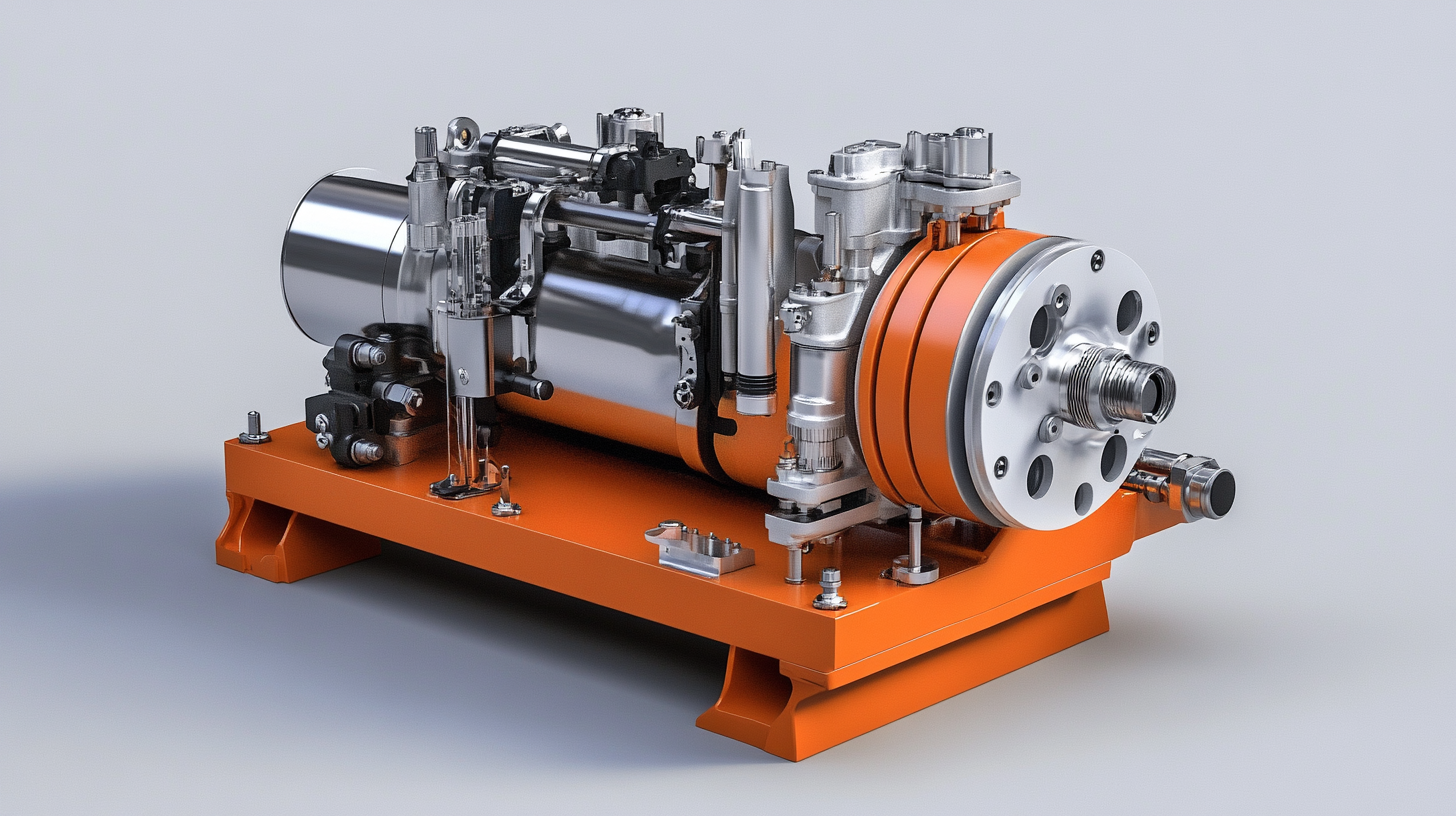

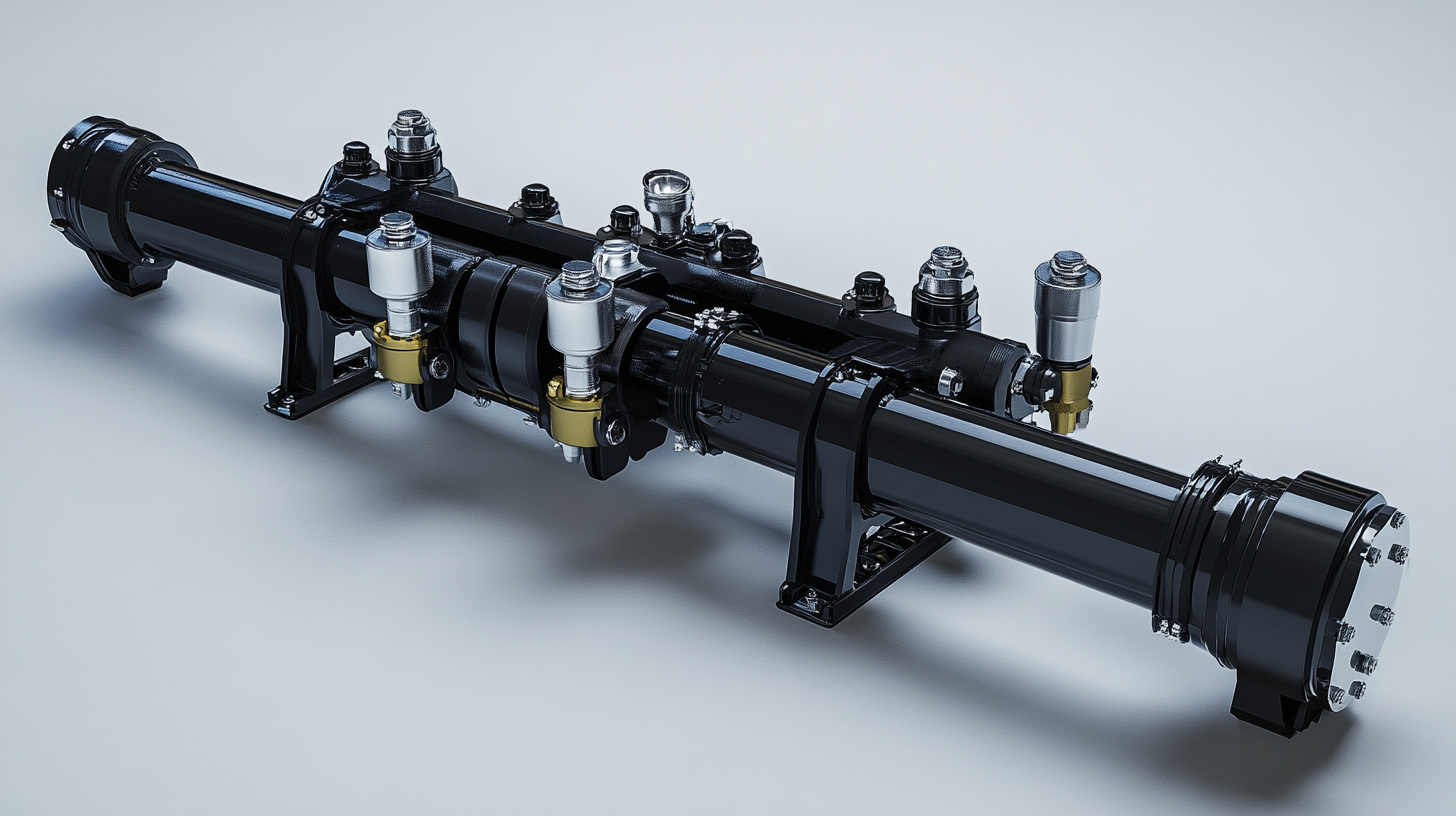

The emergence of innovative hydraulic power recovery turbines exemplifies how technology revolutionizes energy efficiency. These mature systems not only conserve energy but also contribute to revenue generation while minimizing emissions. As businesses prioritize sustainability, the role of such hydraulic solutions in creating greener operations cannot be overstated. Furthermore, the growing interest in small hydropower generation presents a promising avenue, especially in developing regions. By tapping into local resources, these technologies offer an effective means to bolster economic growth and energy independence.

Moreover, novel designs like next-generation hydraulic fracturing systems illustrate the industry's commitment to improving efficiency and environmental, social, and governance (ESG) performance. As the global hydraulic pumps market is projected to witness exponential growth, the emphasis on optimization and advanced system designs continues to drive innovation. Sourcing quality hydraulic solutions manufacturers equipped with cutting-edge technology is thus critical for businesses aiming to enhance operational effectiveness while addressing environmental challenges.

Negotiating Contracts to Ensure Quality and Reliability in Purchases

Negotiating contracts is a crucial step in sourcing quality hydraulic solutions manufacturers. The strength of a contract can determine the reliability of supply, the quality of products, and ultimately the success of partnerships. Effective negotiation goes beyond just price; it involves establishing metrics for performance and quality assurance that can lead to long-term value. Many companies overlook key elements in their contracts, such as performance benchmarks and clear expectations, leaving room for misunderstandings and unmet standards.

One effective strategy for enhancing contract negotiations is to leverage data and analytics. By employing data-driven insights, businesses can identify trends in vendor performance and pinpoint areas for improvement. This strategic approach not only helps in crafting contracts that reflect true market value but also in setting achievable performance goals that both parties can agree upon. In today’s competitive landscape, understanding a vendor's capabilities and reliability is essential; hence, detailed assessments during negotiations can mitigate risks associated with poor supply chain management.

Furthermore, maintaining open communication throughout the negotiation process fosters a collaborative environment. Engaging vendors in discussions about potential challenges and expectations not only clarifies intent but also builds trust. By prioritizing a transparent relationship, both sides can work towards achieving mutually beneficial outcomes, ensuring that the hydraulic solutions procured meet the desired quality standards. This approach ultimately enhances operational efficiency and strengthens the business framework surrounding hydraulic solutions.

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com