Essential Checklist for Choosing the Right Hydraulic Piston Pump for Your Applications

In today's industrial landscape, the significance of selecting the appropriate Hydraulic Piston Pump cannot be overstated. As reported by market analysts, the global market for hydraulic pumps is projected to reach USD 55 billion by 2026, growing at a CAGR of 5.3% from 2020 to 2026. This growth underscores the critical role that hydraulic systems play in various applications, from construction and agriculture to manufacturing and automotive industries. However, choosing the right hydraulic piston pump is not a straightforward task; improper selection can lead to operational inefficiencies, increased maintenance costs, and ultimately, project delays.

Understanding the Critical Applications of Hydraulic Piston Pumps

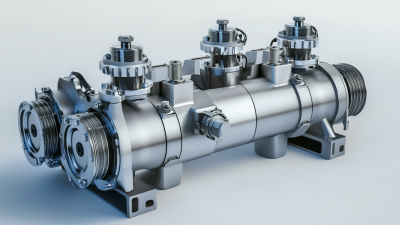

When considering the critical applications of hydraulic piston pumps, it is essential to understand the environments and functions these pumps are best suited for. Hydraulic piston pumps are commonly used in industries such as construction, manufacturing, and automotive, where the demand for high pressure and precision fluid control is paramount. These pumps excel in applications requiring consistent and heavy-duty performance, such as powering hydraulic machinery, lifting equipment, and various hydraulic circuits.

In construction, for instance, hydraulic piston pumps are pivotal in operating excavators, cranes, and loaders. Their ability to generate high hydraulic pressure enables heavy equipment to lift substantial loads effortlessly. Similarly, in the manufacturing sector, these pumps are vital for processes that require precise control of hydraulic fluid, aiding in operations like injection molding, stamping, and die casting. Understanding the specific demands of your application will help in selecting a pump that not only meets your pressure and flow requirements but also ensures reliability and efficiency in your operational processes.

Common Issues Encountered with Hydraulic Piston Pump Types

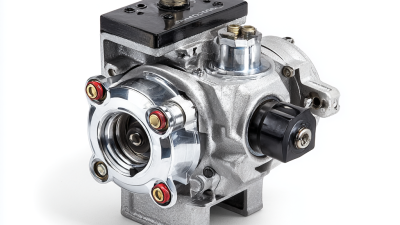

When selecting a hydraulic piston pump, it’s crucial to be aware of common issues that can arise with various types. One primary concern is cavitation, which occurs when the pressure in the pump drops below the vapor pressure of the hydraulic fluid. This phenomenon can lead to significant damage over time. It’s essential to ensure that the pump is appropriately sized and configured for your application to prevent this problem. Additionally, monitoring the fluid levels and maintaining the correct temperature can help mitigate the risk of cavitation.

Another frequent issue involves leakage, which can compromise the efficiency of the hydraulic system. Hydraulic piston pumps are subject to wear and tear, especially at seal points. Leakage not only leads to performance issues but also poses environmental concerns if hydraulic fluids escape into the surroundings. Regular inspection and maintenance of seals and components can help reduce leakage risk and extend the lifespan of the pump.

Finally, contamination of hydraulic fluid poses a notable challenge for piston pumps. Contaminants can cause wear, blockages, and increased operating temperatures, leading to pump failure. Implementing proper filtration systems and adhering to recommended fluid changes are vital practices to combat contamination. By being aware of these common issues when selecting a hydraulic piston pump, you can make informed choices that promote reliability and efficiency in your applications.

Key Features to Evaluate When Selecting a Hydraulic Piston Pump

When selecting a hydraulic piston pump, there are several key features to evaluate to ensure optimum performance for your specific applications. First, consider the pump's displacement and pressure ratings. According to a report by the Fluid Power Society, the efficiency of hydraulic pumps typically ranges from 85% to 90%, depending on the design and operational conditions. A higher displacement can deliver greater flow rates, while appropriate pressure ratings ensure that the pump can handle the required force without compromising safety or functionality.

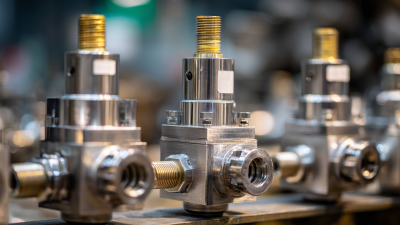

Additionally, examine the pump's construction materials and design. Pumps made with high-grade materials like cast iron or aluminum typically offer greater durability and resistance to wear, significantly decreasing maintenance costs over time. Tip: Always check for certifications that indicate compliance with industry standards, such as ISO or SAE, which serve as a testament to quality and performance.

Lastly, evaluate the pump's compatibility with hydraulic fluids. Different applications may require specific types of hydraulic fluids, which can affect the pump's efficiency and lifespan. A recent industry study indicated that using the correct hydraulic fluid can improve efficiency by up to 15%. Tip: When in doubt, consult with the pump manufacturer to ascertain the best fluid type for your application to avoid potential damage and enhance operational longevity.

Troubleshooting Common Problems in Hydraulic Piston Pumps

Hydraulic piston pumps are essential components in various industrial applications, but they can experience common issues that affect performance. Troubleshooting these problems begins with understanding the most frequent symptoms. For instance, if the pump is producing unusual noises, it may indicate a lack of lubrication or the presence of air in the hydraulic fluid. Regularly checking the fluid levels and ensuring proper maintenance can help prevent these sounds from becoming a persistent issue.

Another common problem is fluctuations in pressure output, which can hinder operation efficiency. This inconsistency might arise from worn-out seals or a malfunctioning relief valve. Inspecting and replacing these components as needed is crucial for maintaining steady pressure levels. Furthermore, operators should be vigilant for any signs of leaks, as they not only affect the pump's performance but can also pose safety hazards. By addressing these common issues promptly, users can ensure the longevity and reliability of their hydraulic piston pumps, ultimately enhancing overall operational effectiveness.

Essential Checklist for Choosing the Right Hydraulic Piston Pump

This chart illustrates common problems in hydraulic piston pumps along with their respective frequencies based on a survey conducted among engineering professionals.

Best Practices for Maintaining Your Hydraulic Piston Pump to Avoid Failures

Maintaining your hydraulic piston pump is crucial to ensure its longevity and optimal performance. Regular inspections are fundamental; they allow you to identify signs of wear and tear before they escalate into significant issues. Checking the oil level, inspecting the hydraulic fluid for contamination, and monitoring temperature levels are simple practices that can prevent unexpected failures. Clean filters and vents regularly to ensure unobstructed fluid flow and maintain efficiency.

Another vital aspect of maintenance is adhering to the manufacturer’s guidelines for servicing and lubrication. Following prescribed schedules for oil changes and using recommended lubricants can drastically reduce the risk of operational failures. It's also important to listen for unusual noises during operation, as they may indicate malfunctions or the need for immediate attention. By fostering a proactive maintenance routine, you can significantly extend the life of your hydraulic piston pump and ensure reliable performance in all applications.

Essential Checklist for Choosing the Right Hydraulic Piston Pump for Your Applications

| Criteria | Description | Best Practices |

|---|---|---|

| Pump Type | Select between variable or fixed displacement based on the application needs. | Evaluate the performance requirements of your hydraulic system. |

| Flow Rate | Ensure the pump can deliver the required flow rate for your application. | Monitor and adjust according to system demands. |

| Pressure Rating | Choose a pump with an appropriate pressure capacity. | Regularly check operational pressure to prevent overloading. |

| Size and Weight | Ensure that the pump size fits well in the intended setup. | Consider accessibility for maintenance during design. |

| Maintenance Requirements | Understand the maintenance needs of the pump. | Implement a regular maintenance schedule to ensure longevity. |

| Installation Ease | Assess how easy it is to install the pump in your existing system. | Follow manufacturer guidelines for installation. |

Related Posts

-

Finding the Right Manufacturer for Quality Hydraulic Pumps

-

Future Trends and Market Insights for Best Hydraulic Pumps by 2025

-

Ultimate Guide to Sourcing the Best Hydraulic Pumps for Your Business Needs

-

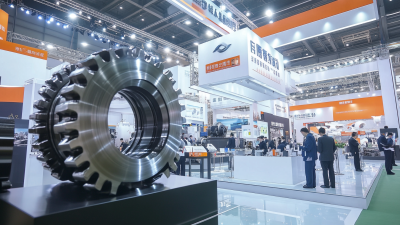

Exploring Global Opportunities for Hydraulic Gear Pumps at the Successful 137th Canton Fair

-

7 Compelling Reasons to Invest in Hydraulic Pumps for Your Business Needs

-

How to Choose the Best Hydraulic Valves for Your Industrial Applications

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com