Unlocking the Potential of Fluid Power Technologies for Global Supply Chain Efficiency

In today's rapidly evolving global economy, manufacturers are constantly seeking innovative solutions to enhance supply chain efficiency. One such solution is Fluid Power technology, which leverages the principles of hydraulics and pneumatics to provide reliable and efficient power transmission. According to the Fluid Power Industry Report 2023, the global fluid power market is projected to reach $80 billion by 2025, driven by increasing demand for automation and smart technologies in various sectors, including manufacturing, construction, and logistics. With its potential to optimize performance through precise control and energy efficiency, Fluid Power is emerging as a key component in modern supply chain strategies.

The application of Fluid Power technologies can lead to significant improvements in operational efficiency and productivity. A recent study by the International Fluid Power Society indicates that companies implementing advanced fluid power systems have reported up to a 30% reduction in energy consumption and a 25% increase in output. As industries face challenges such as rising labor costs and the need for more sustainable practices, Fluid Power offers a viable pathway to not only streamline operations but also enhance competitiveness in a global marketplace. Unlocking the potential of Fluid Power technologies might just be the catalyst needed for companies to achieve a more efficient and resilient supply chain.

The Role of Fluid Power Technologies in Enhancing Supply Chain Agility

Fluid power technologies are becoming pivotal in enhancing supply chain agility, particularly as industries strive to incorporate smarter, more sustainable practices. These technologies are not just about efficiency; they are essential for the adaptability required in today's global supply chains. As highlighted in recent research on sustainable agriculture, such as the Wangree Plant Factory case study, the integration of intelligent technologies has shown remarkable results in productivity. This agricultural advancement mirrors the potential benefits fluid power can bring to logistics and manufacturing sectors, where precision and responsiveness are critical. Moreover, the chemical industry's outlook for 2025 indicates a steady rise in productivity thanks to technology-driven innovations. This trend underscores the importance of proactive supply chain risk management, wherein fluid power technologies play a crucial role. By enhancing the precision of operations and allowing for quick adjustments in production lines, these technologies not only mitigate risks but also promote sustainability through optimized resource use and waste reduction. In a competitive market, agility is key, and fluid power technologies present an avenue for businesses to stay ahead. Companies leveraging these solutions can respond more swiftly to market changes, ensuring their supply chains are not only efficient but also resilient. As we continue to explore the intersection of technology and production, it becomes increasingly clear that fluid power is more than just a mechanism; it's a fundamental component in the quest for supply chain excellence.

Market Trends: The Growing Demand for Fluid Power in Manufacturing and Logistics

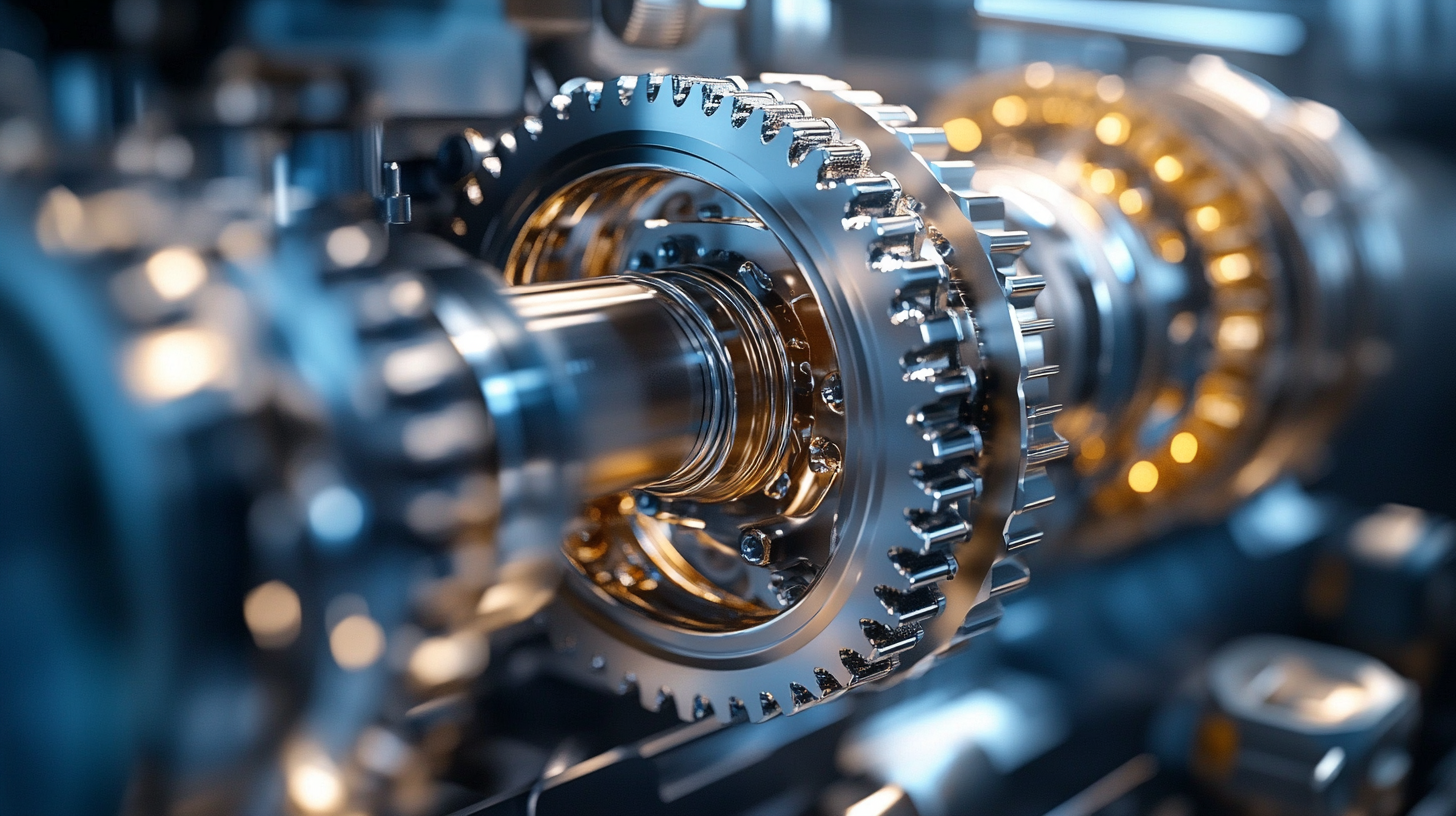

The growing demand for fluid power technologies is reshaping the landscape of manufacturing and logistics, driving efficiency and innovation across global supply chains. As industries increasingly embrace automation, fluid power systems have emerged as essential components, enhancing operational performance and productivity. With the capability to deliver precise control and high power density, these technologies streamline processes, reduce energy consumption, and minimize maintenance costs.

In recent years, the manufacturing sector has witnessed a significant uptick in the adoption of fluid power solutions. Industries reliant on heavy machinery, such as automotive and aerospace, are particularly benefiting from advancements in hydraulic and pneumatic systems. These innovations not only improve the throughput of production lines but also enable manufacturers to respond quickly to changing market demands. Moreover, the integration of fluid power with IoT and smart technologies is paving the way for predictive maintenance and real-time monitoring, ultimately leading to superior supply chain resilience.

Logistics is another area reaping the rewards of fluid power advancements. Automated guided vehicles (AGVs) and robotics, powered by fluid systems, are revolutionizing warehousing and distribution. These systems increase operational agility and optimize inventory management processes. As businesses focus on enhancing supply chain transparency and speed, the role of fluid power technologies will only become more critical, ensuring that teams can meet consumer expectations effectively while driving down costs.

Efficiency Metrics: Quantifying the Impact of Fluid Power Systems on Supply Chain Operations

In the ever-evolving landscape of global supply chains, fluid power technologies have emerged as a critical component in enhancing operational efficiency. By harnessing the dynamics of fluid mechanics, businesses can optimize various processes through hydraulic and pneumatic systems. These technologies offer the potential to significantly reduce energy consumption, increase machine productivity, and improve overall system responsiveness. As companies strive to meet the demands of a competitive market, understanding and quantifying the impact of fluid power systems on supply chain operations becomes imperative.

Efficiency metrics play a central role in evaluating the contributions of fluid power technologies. Key performance indicators (KPIs) such as cycle time reduction, energy efficiency ratios, and maintenance costs provide insight into how these systems can streamline operations. For instance, the implementation of hydraulic systems may lead to faster material handling processes, directly influencing throughput. Moreover, by tracking energy consumption before and after the deployment of fluid technologies, organizations can quantify savings, further solidifying the case for their integration.

It is essential for businesses to not only implement fluid power systems but also to continuously assess their performance through relevant metrics. By doing so, companies can identify areas for improvement, ensure optimal utilization, and adapt to the ever-shifting demands of supply chain dynamics. Ultimately, leveraging fluid power technologies while focusing on efficiency metrics fosters a robust supply chain capable of responding to both current challenges and future opportunities.

Case Studies: Successful Implementations of Fluid Power in Global Supply Chains

Fluid power technologies have emerged as crucial enablers in enhancing the efficiency of global supply chains. Case studies from various industries illustrate how companies are leveraging hydraulic and pneumatic systems to streamline operations and reduce costs. One notable example is a leading automotive manufacturer that implemented a fluid power system in their assembly line. By integrating high-pressure hydraulics into their materials handling process, they were able to significantly decrease cycle times. This allowed for more vehicles to be produced within the same timeframe, ultimately leading to increased throughput and profitability.

Another successful implementation can be seen in the food and beverage sector, where a prominent bottling company adopted pneumatic systems for their packaging lines. The installation of fluid power technology led to improved speed and precision in the filling and capping processes. Furthermore, with the automation capabilities offered by fluid power systems, the company reduced dependence on manual labor, minimizing the risk of workplace accidents and enhancing overall safety. This transformation not only optimized production efficiency but also ensured consistent quality in their products, further strengthening their competitive edge in the market.

These case studies highlight the adaptability of fluid power technologies across different sectors, showcasing their ability to solve unique challenges within global supply chains. As companies look to overcome supply chain disruptions and enhance productivity, fluid power presents a promising solution, offering both reliability and innovation in their operations.

Future Innovations: Emerging Fluid Power Technologies and Their Potential Impact on Supply Chains

Emerging fluid power technologies are poised to revolutionize global supply chains, offering enhanced efficiency and sustainability. These technologies, which encompass hydraulic and pneumatic systems, are increasingly being integrated with smart control systems, enabling real-time data monitoring and predictive maintenance. This integration allows businesses to anticipate failures before they happen, reducing downtime and ensuring that operations run smoothly. As companies face growing pressure to optimize their processes, the adoption of fluid power solutions becomes a strategic advantage.

Innovations like energy-efficient pumps and actuators are transforming how goods are moved and managed within supply chains. For instance, advanced hydraulic systems can operate at lower energy levels while maintaining high performance, which not only cuts operational costs but also reduces the carbon footprint of supply chain activities. Furthermore, the rise of IoT connectivity within fluid power systems equips organizations with invaluable insights, facilitating better resource allocation and inventory management. As we look to the future, the ongoing development of these technologies promises to create more responsive and agile supply chains, capable of adapting to the ever-evolving market demands.

Moreover, the potential for automation in fluid power applications opens new avenues for labor efficiency. With robotic systems powered by fluid technology, tasks such as material handling and assembly can be executed with improved precision and speed, allowing human workers to focus on more complex activities. This shift not only enhances productivity but also drives innovation, as companies leverage fluid power for more creative solutions in logistics and manufacturing. As these technologies continue to advance, they will undoubtedly redefine what is possible in supply chain management.

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com