Unlocking the Future: Innovative Applications of Fluid Power Hydraulics in Modern Industry

In the evolving landscape of modern industry, the application of Fluid Power Hydraulics presents unprecedented opportunities for innovation and efficiency. As sectors such as manufacturing, construction, and transportation seek ways to optimize performance and reduce environmental impact, Fluid Power Hydraulics emerges as a critical technology that can drive significant transformations. By harnessing the principles of fluid mechanics, industries are not only able to enhance the functionality and precision of machinery but also integrate automation and smart technologies seamlessly. This introduction to the innovative applications of Fluid Power Hydraulics explores cutting-edge advancements that are reshaping operational paradigms, from advanced robotic systems to sustainable energy solutions, thereby unlocking a future where efficiency and effectiveness are paramount. In a world increasingly focused on technological integration and sustainability, understanding and leveraging Fluid Power Hydraulics is essential for any organization aiming to thrive in the competitive industrial landscape.

Exploring the Evolution of Fluid Power Hydraulics in Industrial Applications

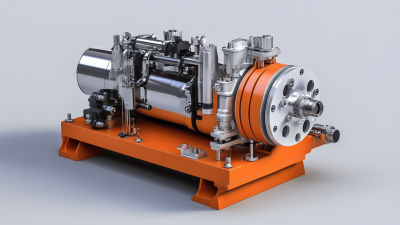

The evolution of fluid power hydraulics has significantly transformed industrial applications over the decades. Initially, hydraulic systems were primarily utilized for basic lifting tasks, but advancements in technology have led to their integration in complex manufacturing processes. Modern industries benefit from enhanced precision, reliability, and efficiency, allowing for faster production cycles and reduced operational costs. Innovations, such as smart hydraulic systems that incorporate IoT technology, enable real-time monitoring and predictive maintenance, further optimizing equipment utilization.

Tips for implementing hydraulic systems successfully include ensuring proper training for operators to maximize system capabilities—knowledge of hydraulics is crucial for troubleshooting and maintenance. Additionally, regular inspections and upgrades can prolong system lifespan and performance. Companies should also focus on selecting the right hydraulic components to match their specific application needs, as this can significantly impact efficiency and safety. The journey of fluid power hydraulics is ongoing, pushing the boundaries of what is achievable in modern industrial applications, paving the way for smarter, more sustainable production methods.

Understanding the Advantages of Fluid Power Systems Over Traditional Mechanisms

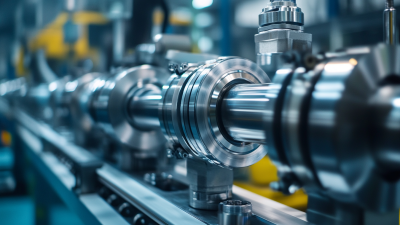

Fluid power systems have gained significant traction in modern industrial applications, primarily due to their distinct advantages over traditional mechanical mechanisms. One of the most notable benefits is their ability to provide smooth and precise control of force and motion. Unlike mechanical systems, which often rely on gears and levers that can introduce backlash and wear over time, fluid power systems utilize hydraulic fluids to transmit energy, resulting in more consistent performance and reduced maintenance needs.

Additionally, fluid power systems are capable of generating significant power in a compact form. This enables manufacturers to design equipment that is both powerful and space-efficient, a crucial factor in industries where floor space is at a premium. The versatility of fluid power technology also allows for straightforward scalability, accommodating varying operational demands without the need for extensive mechanical modifications. This adaptability not only enhances operational efficiency but also contributes to sustainability efforts by reducing energy consumption and waste in industrial processes.

Unlocking the Future: Innovative Applications of Fluid Power Hydraulics in Modern Industry

| Application Area | Advantages of Fluid Power | Comparison with Traditional Mechanisms | Typical Use Cases |

|---|---|---|---|

| Construction Machinery | High power-to-weight ratio | More compact systems than electric motor drives | Excavators, Loaders |

| Aerospace Systems | Reliable performance in extreme conditions | Fewer points of failure compared to mechanical systems | Landing gear systems, flight control surfaces |

| Manufacturing Automation | Precise control of force and motion | More intuitive adjustments versus mechanical gears | Robotic arms, material handling |

| Automotive Industry | Enhanced safety features through responsive systems | Faster response times compared to conventional brakes | Power steering, brake systems |

| Marine Applications | Ability to perform under water conditions | Minimized corrosion-related failures | Deck machinery, winches |

Analyzing Innovative Technologies Impacting Hydraulics in Modern Manufacturing

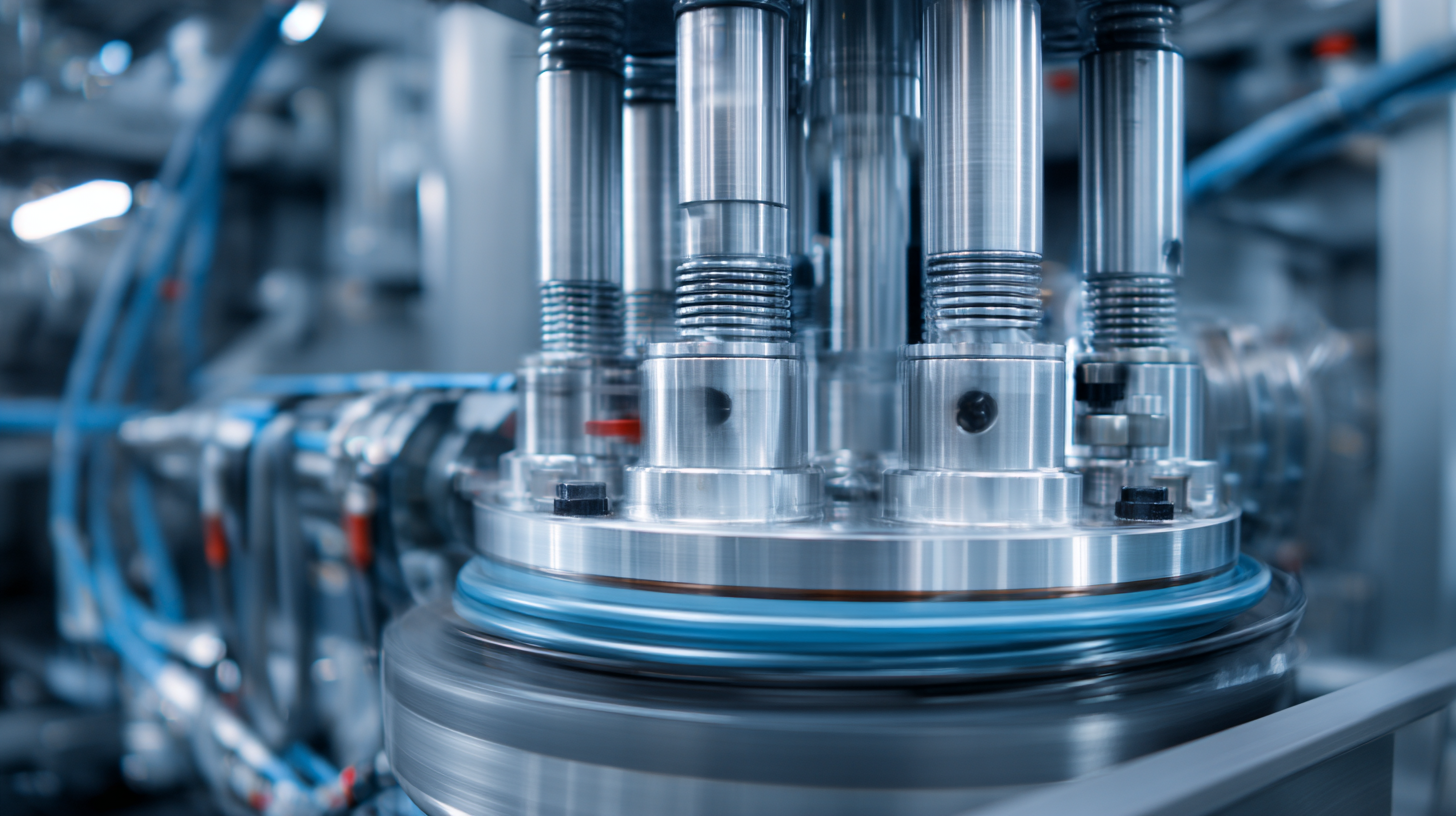

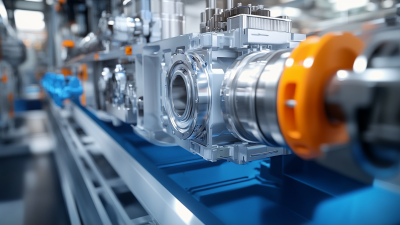

Fluid power hydraulics is experiencing a transformative phase in modern manufacturing, driven by innovative technologies that enhance efficiency and precision. Advanced sensors and control systems are at the forefront of this evolution, allowing for real-time monitoring and adjustments in hydraulic systems. These developments enable manufacturers to achieve higher levels of automation, leading to improvements in productivity and reduced operational costs. Moreover, the integration of the Internet of Things (IoT) into hydraulic applications has facilitated predictive maintenance, minimizing downtime and enhancing system reliability.

Additionally, the advent of smart materials and energy-efficient designs has further revolutionized the hydraulic landscape. These materials respond intelligently to changes in pressure and temperature, optimizing performance while conserving energy. This shift not only supports sustainable manufacturing practices but also meets the increasing demands for both high-performance machinery and ecological responsibility. The continued exploration of innovative applications in fluid power hydraulics promises to redefine operational standards in the industry, positioning manufacturers for future success.

Innovative Applications of Fluid Power Hydraulics in Modern Industry

This chart illustrates the growing applications of fluid power hydraulics across various segments of modern manufacturing, emphasizing their impact on efficiency and productivity.

Case Studies: Successful Implementations of Fluid Power in Various Industries

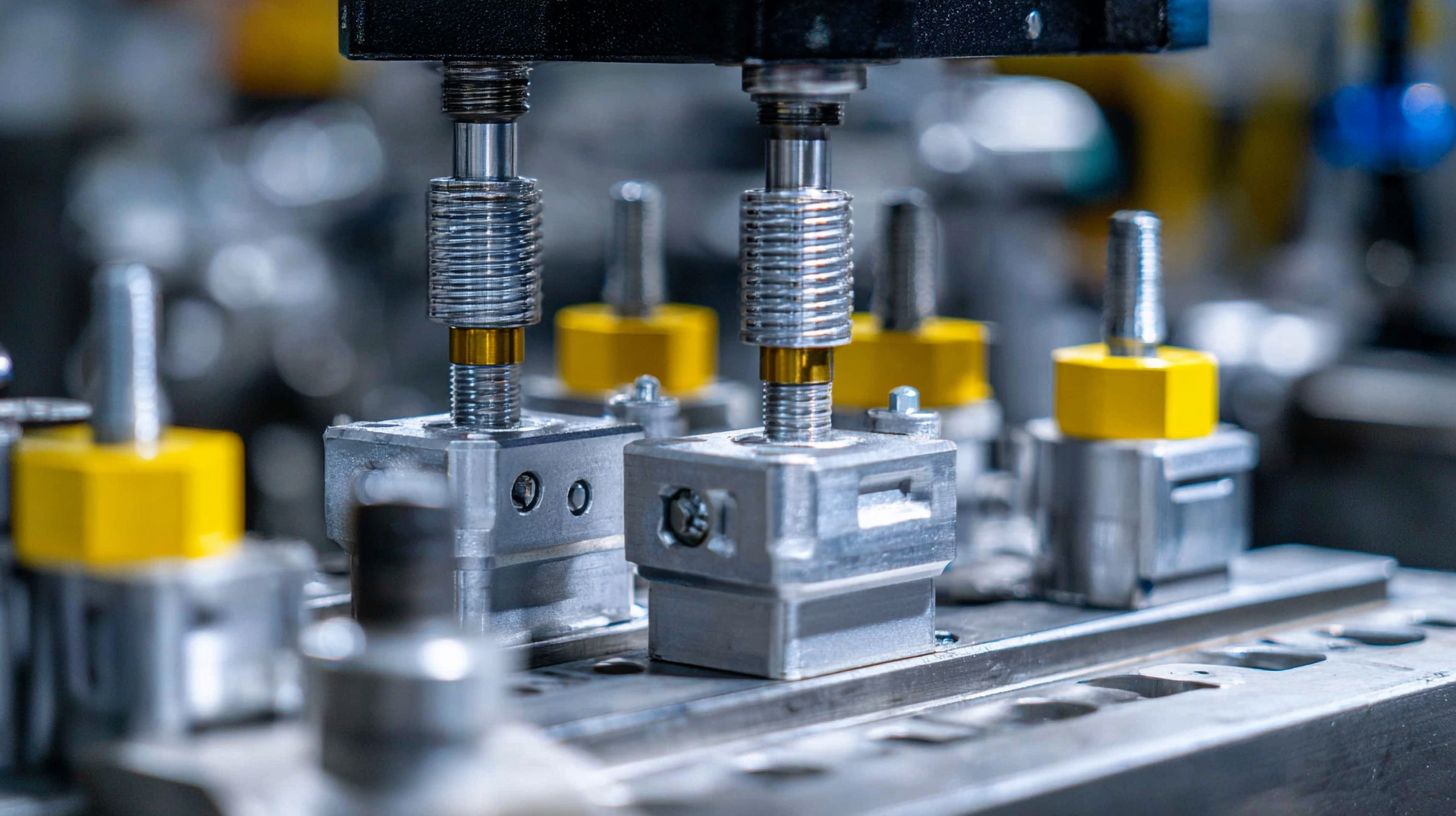

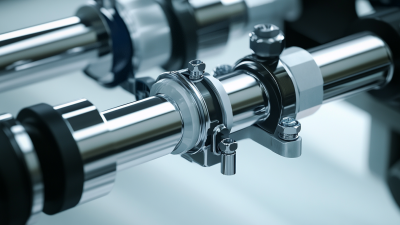

Fluid power hydraulics has become a cornerstone of innovation across diverse industries, demonstrating remarkable applications that enhance efficiency and productivity. One compelling case study is found in the automotive sector, where hydraulic systems are instrumental in assembly lines. For instance, a leading automobile manufacturer integrated advanced hydraulic presses for shaping vehicle components. This implementation not only accelerated production times but also improved the precision of the parts, minimizing waste and optimizing resource usage.

Fluid power hydraulics has become a cornerstone of innovation across diverse industries, demonstrating remarkable applications that enhance efficiency and productivity. One compelling case study is found in the automotive sector, where hydraulic systems are instrumental in assembly lines. For instance, a leading automobile manufacturer integrated advanced hydraulic presses for shaping vehicle components. This implementation not only accelerated production times but also improved the precision of the parts, minimizing waste and optimizing resource usage.

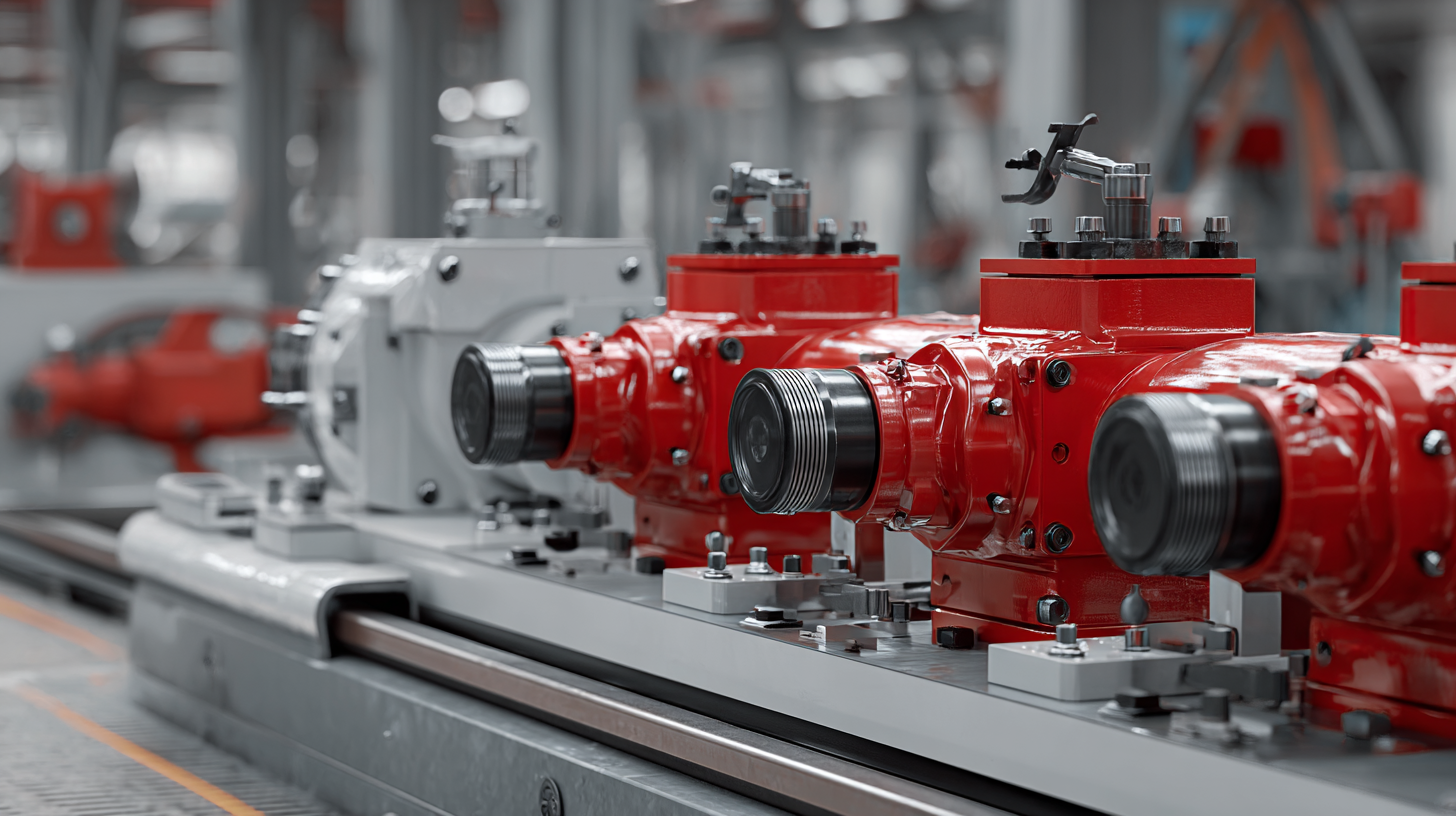

In the construction industry, fluid power is transforming the way heavy machinery operates. A notable example is the use of hydraulic excavators equipped with innovative control systems that allow for more ergonomic operation and finer movements. These advancements enable operators to perform tasks with higher accuracy and less physical strain, ultimately leading to enhanced safety on construction sites. Furthermore, such machinery can adapt to various tasks with speed, illustrating the versatility of hydraulic systems and their critical role in evolving industry standards.

Future Trends: The Role of Fluid Power in Sustainable Industrial Practices

The role of fluid power hydraulics in modern industry is evolving rapidly, especially in the context of sustainable practices. As industries increasingly adopt sustainable solutions, fluid power systems are proving to be integral. According to recent market analysis, the global Computer-Aided Engineering (CAE) market size is projected to reach $7072.3 million by 2025, with an anticipated growth rate reaching $12,993.7 million by 2033, reflecting a compound annual growth rate (CAGR) of 7.9%. This growth underscores the significance of innovative hydraulic applications that enhance operational efficiency while minimizing environmental impact.

Incorporating fluid power technology can lead to substantial energy savings and reduced emissions, aligning with global sustainability goals. Businesses can leverage innovations such as energy-efficient hydraulic circuits and advanced control systems to optimize their processes. Tips for organizations looking to adopt fluid power sustainably include regularly assessing hydraulic system efficiency, investing in training for employees about new technologies, and exploring the integration of renewable energy sources into fluid power systems.

As industries seek a competitive edge, the shift towards sustainable practices will likely bolster the adoption of advanced fluid power hydraulics. Focusing on innovative applications not only enhances operational capabilities but also positions companies favorably in the evolving landscape of responsible manufacturing.

Related Posts

-

Innovative Solutions for Best Fluid Power Applications in Global Markets

-

Essential Tips for Selecting Top Quality Fluid Power Hydraulics Suppliers: A Data-Driven Approach

-

Discover Effective Strategies for Sourcing Quality Hydraulic Solutions Manufacturers

-

Unlocking the Potential of Fluid Power Technologies for Global Supply Chain Efficiency

-

Fluid Power Hydraulics vs Pneumatics Key Insights for Global Buyers

-

Exploring Innovative Examples of Best Hydraulic Solutions for Your Business Needs

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com