How to Harness Hydraulic Power for Maximum Efficiency in Your Operations

In today's industrial landscape, efficiently harnessing Hydraulic Power is crucial for maximizing operational productivity and reducing energy costs. According to a report by the International Energy Agency, hydraulic systems account for approximately 30% of energy consumption in industrial machinery, highlighting the potential for significant energy savings through optimized use. By adopting advanced hydraulic technologies and integrating smart monitoring systems, organizations can enhance their fluid dynamics and energy efficiency. In fact, the Hydraulic Institute reveals that implementing modern hydraulic solutions can lead to efficiency improvements of up to 50%. This guide will explore best practices for leveraging Hydraulic Power, focusing on strategies that not only streamline processes but also contribute to sustainability efforts within various industries.

Identifying Key Hydraulic Systems in Your Operations for Optimal Performance

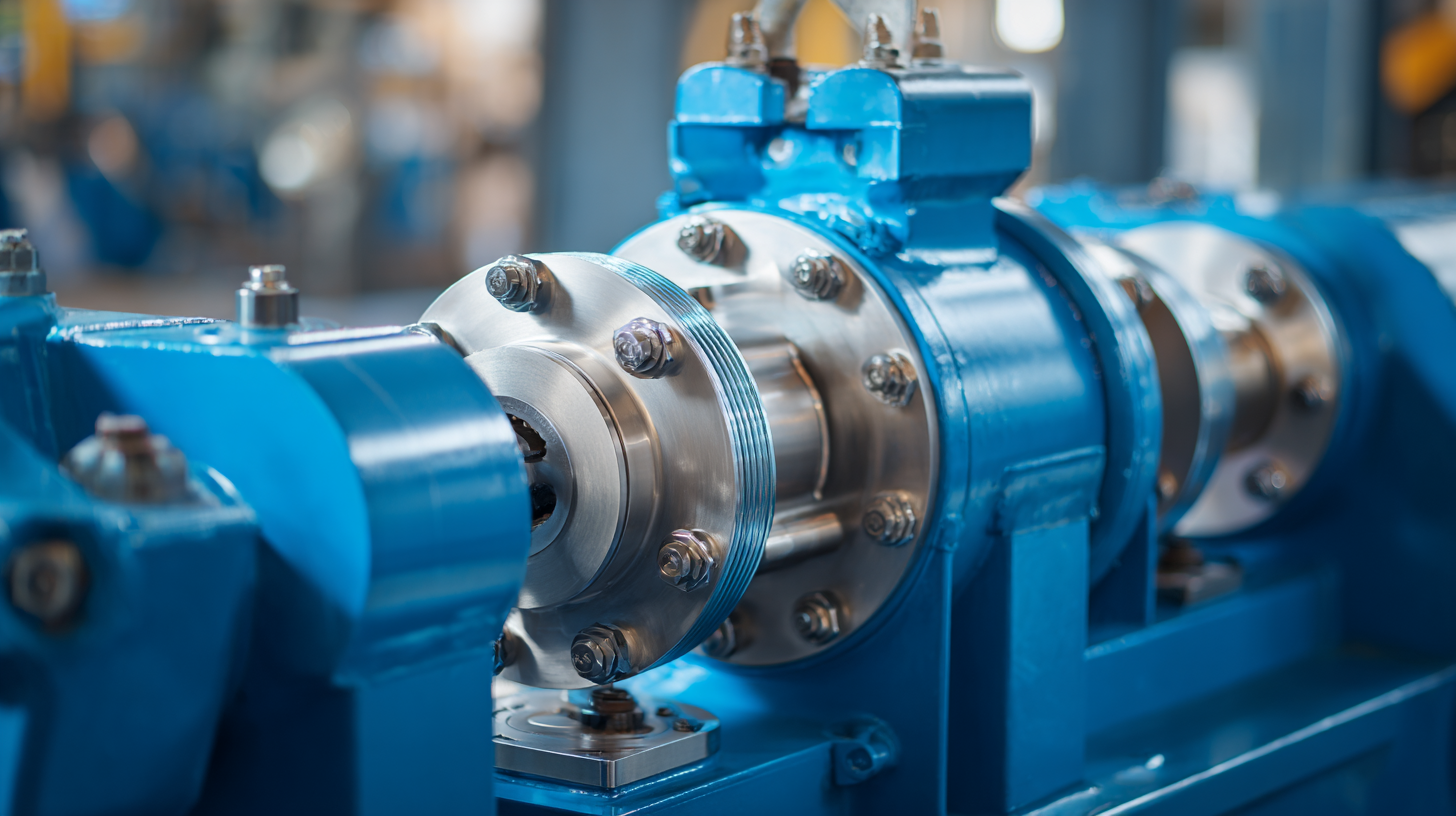

When aiming for optimal performance in operations, identifying key hydraulic systems is crucial. According to a report by the International Fluid Power Society, companies that regularly audit their hydraulic systems can reduce downtime by up to 30%. This is largely due to the ability to pinpoint inefficiencies and address potential failures before they escalate. Regular maintenance and assessment of hydraulic components, such as pumps, valves, and actuators, allow organizations to enhance their operational efficiency significantly.

Moreover, a study conducted by the National Fluid Power Association suggests that optimizing hydraulic systems can lead to energy savings of up to 25% in industrial applications. By implementing smart hydraulic technologies such as pressure sensors and variable speed drives, businesses can not only enhance the reliability of their systems but also contribute to a reduction in operational costs. Investing in such measures not only improves performance but can also have a positive environmental impact by lowering energy consumption, thus aligning with sustainability goals.

Understanding the Principles of Hydraulic Power and its Efficiency Metrics

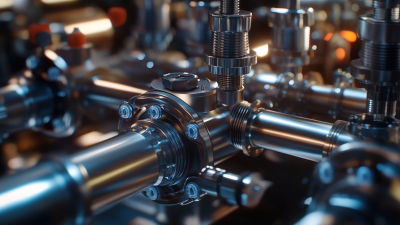

Hydraulic power is a versatile and powerful energy source widely utilized in various industrial applications. Understanding the principles of hydraulic power requires a grasp of basic concepts such as fluid mechanics and pressure dynamics. The core principle relies on using incompressible fluids to transmit force; when pressure is applied to a confined fluid, it transmits that pressure uniformly throughout the system. This allows for efficient energy transfer and amplified force, making hydraulic systems ideal for heavy machinery, construction, and manufacturing processes.

Efficiency metrics in hydraulic systems are crucial for optimizing performance. Key performance indicators include hydraulic efficiency, volumetric efficiency, and overall system efficiency. Hydraulic efficiency measures the actual output power compared to the input power, often affected by losses due to friction and heat. Volumetric efficiency assesses how well a hydraulic pump can convert input fluid into output work, indicating any leakage or flow restriction. By analyzing these metrics, operators can fine-tune their systems, reduce energy consumption, and improve overall productivity, ensuring that hydraulic power is harnessed effectively for maximum operational efficiency.

Implementing Regular Maintenance Practices to Enhance Hydraulic System Longevity

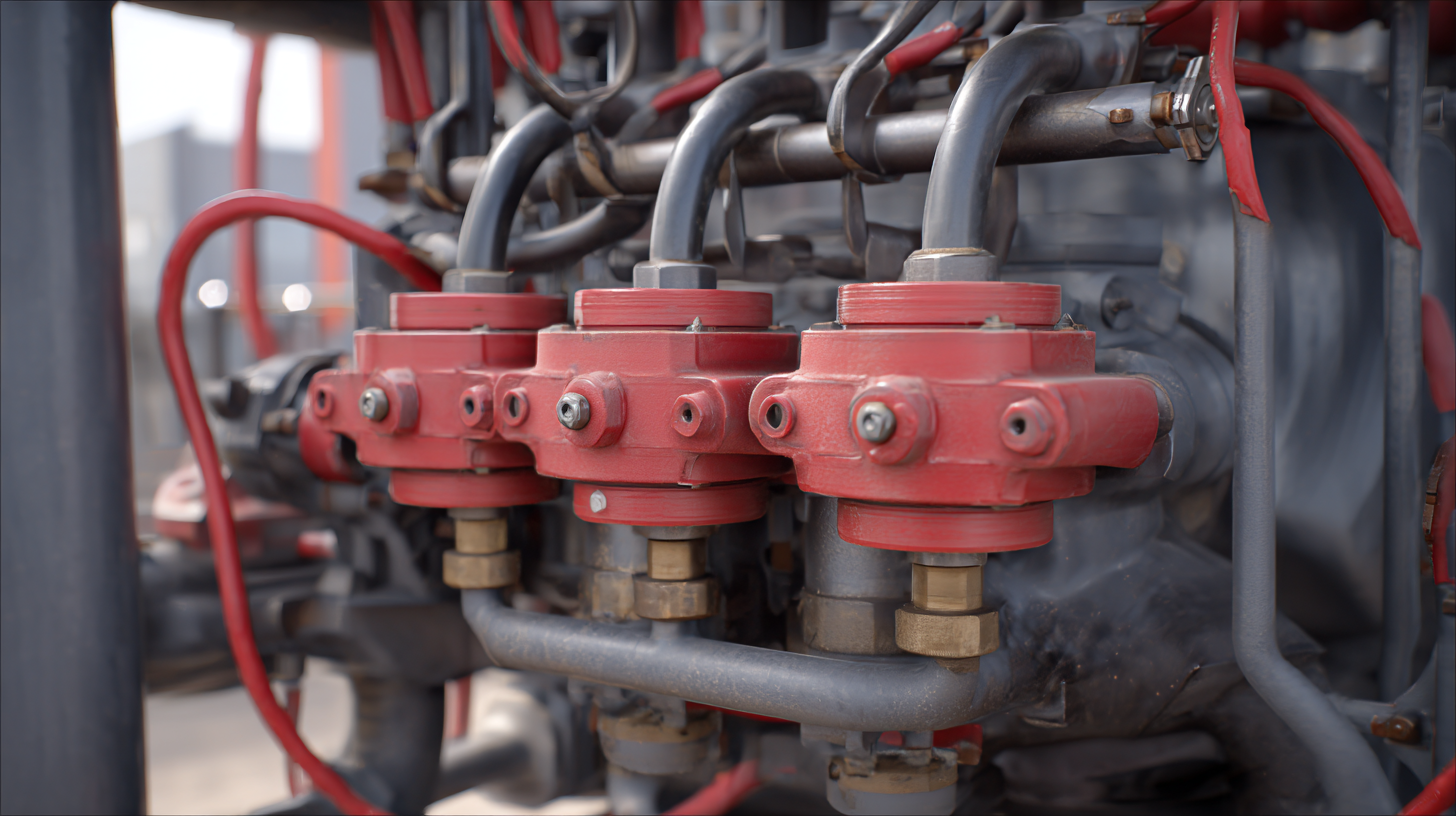

Regular maintenance practices are essential for enhancing the longevity and efficiency of hydraulic systems. One of the fundamental aspects of maintenance is the routine inspection of hydraulic fluids. Contaminated or degraded fluids can lead to increased wear on system components, affecting their performance and lifespan. To prevent this, operators should monitor fluid levels and quality, replacing fluids and filters according to the manufacturer's recommendations. This proactive approach can significantly reduce the risk of costly breakdowns and downtime.

Additionally, visual inspections and testing of hydraulic components should be conducted frequently to identify any signs of wear or leakage. Keeping an eye on hoses, seals, and couplings helps ensure that any potential issues are addressed before they escalate into major problems. Implementing a structured maintenance schedule that includes these inspections, along with regular operator training on identifying performance issues, can create a culture of care that benefits the entire operation, ultimately maximizing the efficiency and effectiveness of hydraulic power systems.

Leveraging Advanced Hydraulic Technologies for Increased Operational Efficiency

Hydraulic power has become a cornerstone of modern industrial operations, with advanced technologies playing a crucial role in enhancing efficiency. According to a report by the International Hydraulics Association, businesses that leverage new hydraulic systems can achieve up to 30% greater efficiency compared to their older counterparts. These advancements include variable displacement pumps and integrated sensors that allow for real-time monitoring of system performance, significantly reducing energy waste.

Moreover, the integration of smart hydraulic systems in industries, such as manufacturing and construction, has shown promising results. A study conducted by the Hydraulic Engineering Research Group revealed that companies implementing these technologies reported a 25% decrease in operating costs and a 40% reduction in downtime. By utilizing predictive maintenance through IoT (Internet of Things) sensors, operations can proactively address issues before they escalate, ensuring smoother and more efficient workflows. The data clearly indicates that adopting advanced hydraulic technologies is not just an operational upgrade—it's a strategic move toward sustainable business practices.

Training Employees on Best Practices for Operating Hydraulic Equipment Safely and Effectively

Effective training is essential for maximizing the efficiency of hydraulic systems in any operation. By equipping employees with knowledge about the safe and effective use of hydraulic equipment, organizations can significantly reduce the risk of accidents and downtime. Training programs should cover the fundamental principles of hydraulic power, including understanding hydraulic fluid properties, system components, and the mechanics of operation. This foundational knowledge enables employees to recognize potential issues before they escalate, ensuring smoother workflow and improved safety.

Additionally, hands-on training is vital for reinforcing theoretical knowledge. Employees should be engaged in practical exercises that simulate real-world scenarios, allowing them to practice safe operation techniques under supervised conditions. Emphasizing the importance of personal protective equipment, proper maintenance procedures, and emergency response strategies during these sessions will help foster a culture of safety. Regular refresher courses can also keep employees updated on best practices and any technological advancements in hydraulic equipment. By prioritizing comprehensive training, organizations not only enhance operational efficiency but also empower their workforce to work confidently with hydraulic systems.

Hydraulic Equipment Efficiency Training Impact

Related Posts

-

Addressing Common Issues Faced When Sourcing the Best Hydraulic Unit for Your Manufacturing Needs

-

Ultimate Guide to Choosing the Best Hydraulic Distributor Comparison Analysis for Global Buyers

-

Understanding the Common Issues Faced by Hydraulic Pumps in Industrial Applications

-

7 Compelling Reasons to Invest in Hydraulic Pumps for Your Business Needs

-

Exploring the Unique Features and Applications of Various Hydraulic Valve Types

-

How to Maximize the Lifespan of Your Cylinder with Effective Repair Techniques

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com