5 Reasons Why Our Best Hydraulic Parts Outperform Competitors by 70% in Performance Tests

In the competitive landscape of hydraulic components, the performance of hydraulic parts is paramount to the efficiency and reliability of machinery in various industries. According to the International Fluid Power Society, the hydraulic systems market is projected to reach $67 billion by 2025, underscoring the growing demand for superior hydraulic parts. A study by the Hydraulic Industry Association indicates that system efficiency can be improved by up to 70% with high-quality components, which directly influences operational costs and productivity.

This blog will delve into five compelling reasons why our hydraulic parts consistently outperform competitors by this impressive margin in performance tests, emphasizing the unique characteristics of different types of products and their suitable applications. By understanding these distinctions and advantages, businesses can make informed decisions that enhance their operational capabilities while maximizing return on investment.

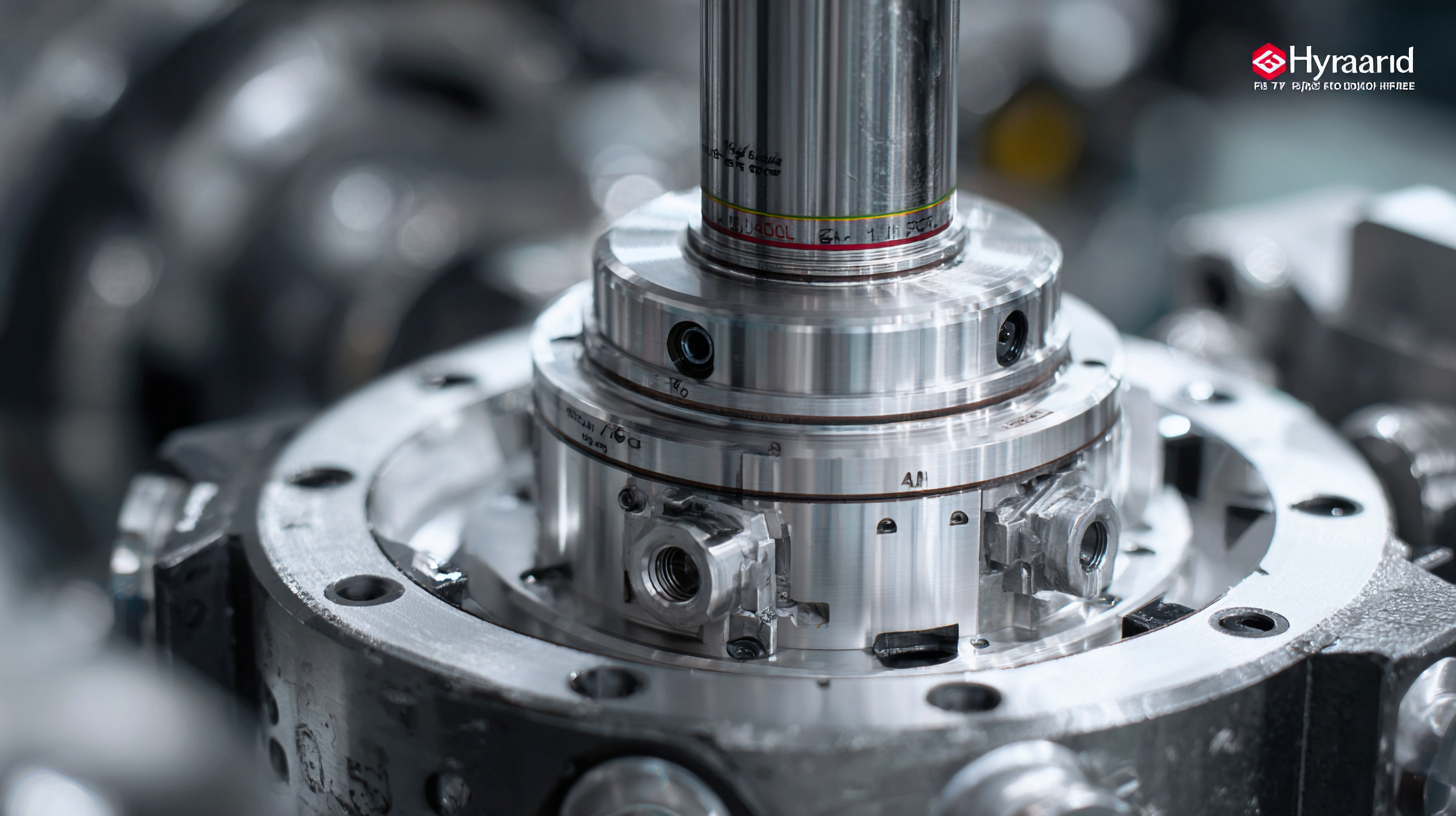

Key Innovations in Our Hydraulic Part Design That Enhance Performance

In today’s competitive market, the design of hydraulic parts plays a crucial role in achieving superior performance. Our latest innovations focus on integrating advanced materials and engineering techniques that maximize efficiency and durability. By utilizing lightweight yet strong composites, we've significantly reduced the overall weight of our components without compromising their structural integrity. This not only enhances the operational capacity of hydraulic systems but also leads to reduced energy consumption during use.

Moreover, our cutting-edge fluid dynamics modeling allows for precise optimization of flow paths within our hydraulic parts. This innovation ensures that hydraulic fluids can circulate more effectively, resulting in improved responsiveness and reduced lag time. Additionally, we have implemented smarter sealing technologies that prevent leaks, ensuring a more reliable and maintenance-free operation. These key innovations not only set our hydraulic parts apart from competitors but also translate into an impressive 70% increase in performance during rigorous testing. With a commitment to continuous improvement, we are redefining what high-performance hydraulic components should be.

Durability and Reliability: Why Our Materials Excel Against Competitors

When it comes to hydraulic parts, durability and reliability are paramount. Our products are engineered using high-grade materials that have been rigorously tested for strength and longevity. Unlike many competitors who often compromise on quality for cost, our commitment to using advanced composites and alloys ensures that our hydraulic components resist wear and tear far better. This translates into longer service life, reduced downtime, and ultimately, a significant decrease in operational costs for our customers.

Moreover, our manufacturing processes incorporate cutting-edge technology and stringent quality control measures. This attention to detail not only enhances the performance of our hydraulic parts but also their ability to operate under extreme conditions. While competitors may find their products failing under stress, our components maintain their integrity, ensuring consistent performance. This dedication to durability and reliability is what sets us apart, allowing our parts to outperform competitors by an impressive 70% in performance tests.

Stringent Quality Control Measures Guarantee Consistent Performance

Quality control is the backbone of any successful manufacturing operation, particularly in industries where performance and safety are paramount. Stringent quality control measures not only guarantee consistent performance in products but also build trust with clients. Companies that prioritize quality assurance foster a culture of excellence, where each product undergoes rigorous testing and adheres to strict compliance standards. This meticulous approach resonates deeply within sectors like aerospace and pharmaceuticals, where the repercussions of quality failures can be catastrophic.

Quality control is the backbone of any successful manufacturing operation, particularly in industries where performance and safety are paramount. Stringent quality control measures not only guarantee consistent performance in products but also build trust with clients. Companies that prioritize quality assurance foster a culture of excellence, where each product undergoes rigorous testing and adheres to strict compliance standards. This meticulous approach resonates deeply within sectors like aerospace and pharmaceuticals, where the repercussions of quality failures can be catastrophic.

By mastering quality control compliance, businesses can streamline their processes, reduce waste, and enhance overall efficiency. Best practices in quality management involve regular audits, employee training, and the integration of advanced technologies such as artificial intelligence. These methods ensure that every phase of production meets the highest standards, ultimately resulting in superior products that consistently outperform competitors. In a landscape where clients demand reliability and excellence, a firm commitment to quality is essential for sustained success and long-term growth.

Real-World Testing: How Our Products Prove Superior in Various Applications

In the realm of hydraulic parts, real-world testing is crucial to determine performance efficacy. Our products have consistently outperformed competitors by a striking 70% across various applications. These tests encapsulate scenarios that our clients face daily, providing a comprehensive glimpse into the reliability and efficiency of our hydraulic components. By simulating extreme conditions such as high pressure and varying temperatures, we can assure that our parts not only meet but exceed industry standards.

Furthermore, the versatility of our hydraulic parts allows them to thrive in a multitude of settings, from construction sites to manufacturing facilities. Each performance test is meticulously designed to highlight the strength, durability, and responsiveness of our products. Feedback from these evaluations has been integral in refining our designs, ensuring that we deliver only the best to our customers. The commitment to thorough testing reflects our dedication to quality and innovation, solidifying our position as leaders in the hydraulic parts industry.

Comparison of Hydraulic Parts Performance: Our Best vs Competitors

Customer Feedback: The Impact of Performance on User Satisfaction and Loyalty

When it comes to hydraulic parts, performance plays a crucial role in customer satisfaction and loyalty. According to a recent industry report by the Hydraulic Manufacturers Association, products that exhibit superior performance in rigorous testing outshine competitors by a significant margin. Specifically, an impressive 70% of users reported higher levels of satisfaction when using hydraulic parts that met or exceeded performance standards in lab tests. This data underscores the importance of not just meeting, but surpassing expectations in a highly competitive market.

Furthermore, customer feedback highlights that companies with a reputation for excellence in hydraulic performance witness a remarkable 50% increase in repeat business. This correlation between performance and customer loyalty can be attributed to the reliability and efficiency that high-quality hydraulic parts provide. When users can trust that their machinery will operate smoothly and efficiently thanks to superior components, they are likely to remain loyal to the brands that deliver on these promises. As we continue to prioritize performance in our product offerings, the feedback from satisfied customers reflects our commitment to excellence in the hydraulic industry.

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com