Why Hydraulic Valves are Essential for Optimizing Industrial Fluid Control Systems: Key Insights and Data

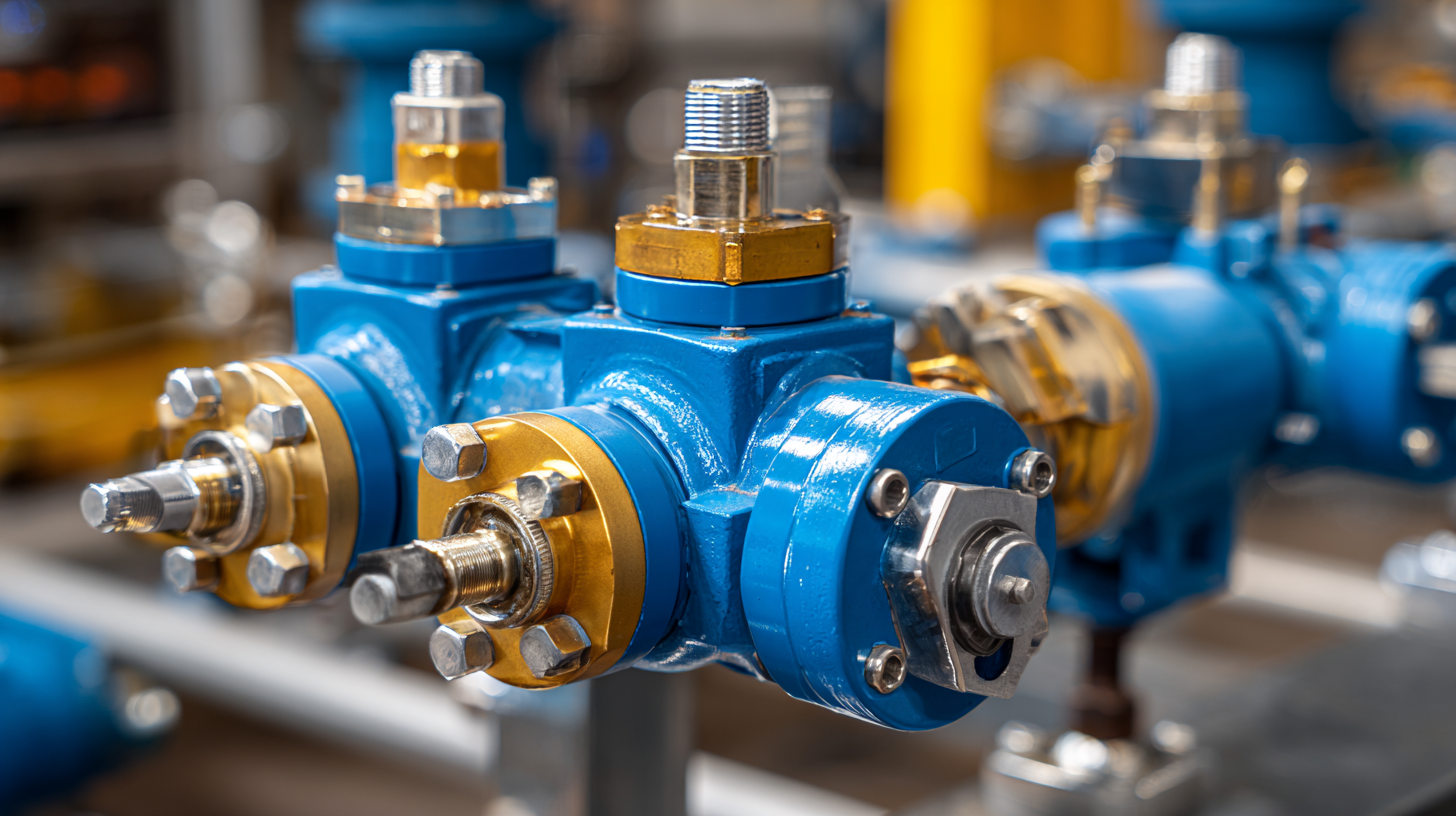

In the evolving landscape of industrial fluid control systems, the significance of Hydraulic Valves cannot be overstated. These critical components facilitate the management of fluid flow and pressure, ensuring efficient system operation across various applications. According to a report by MarketsandMarkets, the global hydraulic valves market is expected to reach $6.4 billion by 2025, growing at a CAGR of 4.6%. This underscores the increasing demand for reliable and high-performance hydraulic solutions that can enhance operational efficiency and reduce energy consumption in industries ranging from manufacturing to aerospace.

As industries strive for greater automation and precision, the optimization of fluid control systems becomes paramount. Hydraulic Valves play a pivotal role in achieving this optimization by providing accurate control of hydraulic fluid movement, which is essential for the functionality of machinery and equipment. A recent study by Grand View Research highlights that advancements in hydraulic system technology are driving the adoption of more sophisticated valve designs, enabling improved performance and reliability. By leveraging advanced hydraulic valve technologies, companies can address challenges such as system inefficiencies and downtime, ultimately leading to enhanced productivity and cost savings in their operations.

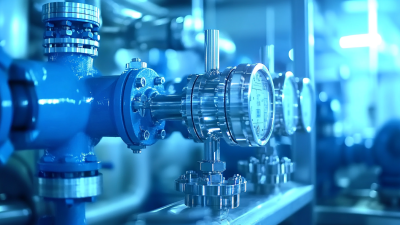

Importance of Hydraulic Valves in Industrial Fluid Systems

Hydraulic valves play a crucial role in industrial fluid control systems, acting as the backbone of operation efficiency and reliability. According to a report by Market Research Future, the global hydraulic valves market is projected to reach USD 7.16 billion by 2026, growing at a CAGR of 6.5%. This growth underscores the increasing importance of these components in various industries, including manufacturing, construction, and oil and gas, where precise fluid control is essential for optimal performance.

The proper functioning of hydraulic valves ensures effective pressure regulation and flow control, directly impacting equipment longevity and operational safety. Data from the National Fluid Power Association indicates that hydraulic systems can deliver up to three times the power compared to electric systems, primarily due to the efficiency of hydraulic valves in managing fluid dynamics. By minimizing pressure drops and preventing fluid leakage, these valves contribute significantly to energy conservation and reduce operational costs, making them indispensable in modern industrial applications.

Why Hydraulic Valves are Essential for Optimizing Industrial Fluid Control Systems: Key Insights and Data

| Dimension | Data |

|---|---|

| Types of Hydraulic Valves | Directional Control, Pressure Relief, Flow Control, Check Valves |

| Common Applications | Manufacturing, Construction, Aerospace, Agriculture |

| Average Lifespan | 10-15 years |

| Typical Operating Pressure | 500 to 3000 psi |

| Efficiency Improvement | Up to 30% with proper valve selection |

| Maintenance Frequency | Every 6-12 months |

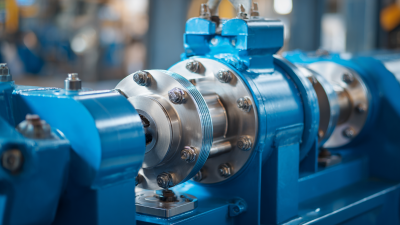

Key Benefits of Utilizing Hydraulic Valves for Enhanced Efficiency

Hydraulic valves play a crucial role in optimizing industrial fluid control systems by enhancing efficiency across various applications. Utilizing these valves leads to significant improvements in system performance, particularly in sectors like mobile hydraulic equipment, which is projected to reach USD 58.4 billion by 2034, growing at a CAGR of 6.1% from 2025. These valves not only regulate fluid flow but also contribute to energy efficiency, thereby reducing operational costs and boosting overall productivity.

Moreover, the expansion of the hydraulic hoses market, which currently holds a 54.30% share and is expected to grow to around USD 18.6 billion by 2034, highlights the increasing demand for reliable hydraulic components. Enhanced PID control strategies, particularly those incorporating advanced algorithms, further underscore the trend towards sophisticated hydraulic systems that maximize efficiency. By integrating these technological advancements, industries can achieve higher operational standards while paving the way for innovative practices in fluid control and automation.

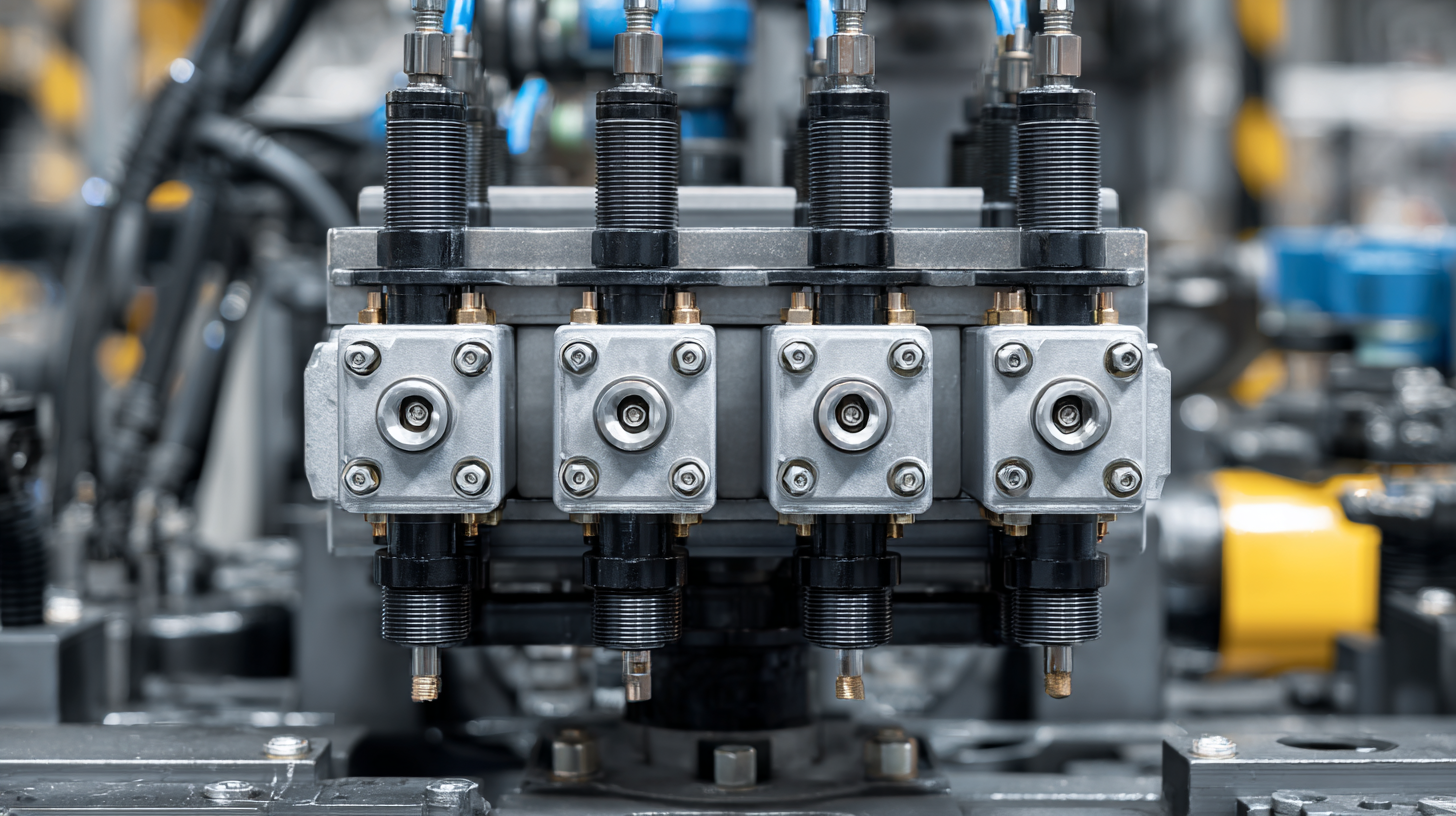

Comparative Analysis of Hydraulic Valve Types and Their Applications

Hydraulic valves are pivotal components in industrial fluid control systems, influencing efficiency and functionality across various applications. A comparative analysis of hydraulic valve types reveals distinct characteristics and benefits suited for different operational conditions. For instance, directional control valves are designed to regulate the flow of hydraulic fluid in specific paths, making them essential in systems requiring precise actuator movements. According to a report by MarketsandMarkets, the global hydraulic valve market is expected to grow from $11.8 billion in 2021 to $15.5 billion by 2026, emphasizing the increasing reliance on these components across various industries.

Pressure relief valves, on the other hand, play a critical role in maintaining system safety and preventing overpressure scenarios that could lead to catastrophic failures. These valves are crucial in industries such as oil and gas, where the risk associated with high-pressure systems is significant. A study by Grand View Research indicates that the demand for pressure control equipment, including valves, will witness a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028, underscoring the essential nature of these devices in fluid control systems. Understanding the different valve types and their applications is key for engineers and operators aiming to enhance system reliability and performance.

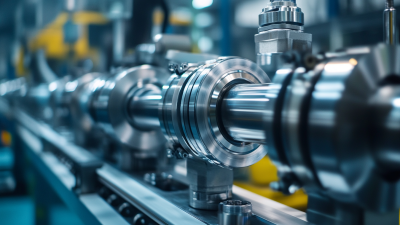

Data-Driven Insights on Hydraulic Valve Performance Metrics

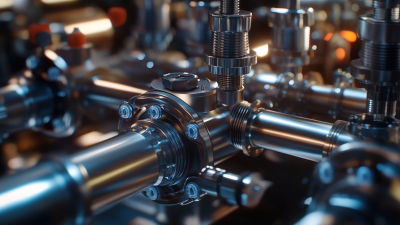

Hydraulic valves play a pivotal role in the efficiency of industrial fluid control systems. By regulating flow rates and directing pressurized fluid to various components, these valves contribute significantly to the overall performance of hydraulic systems. Recent data-driven analyses reveal that the effectiveness of hydraulic valves can be measured through several key performance metrics, including response time, leakage rates, and operational lifespan. Understanding these metrics enables engineers to select the most appropriate valves for specific applications, thereby optimizing system performance.

For instance, response time is critical in applications requiring rapid fluid modulation. Advanced hydraulic valves designed with minimal lag times can significantly enhance system responsiveness, leading to improved operational accuracy and safety. Additionally, monitoring leakage rates is essential for maintaining system efficiency and reducing operational costs. Data has shown that modern sealing technologies in hydraulic valves can reduce leakage significantly compared to older designs. Furthermore, evaluating the operational lifespan of valves through predictive maintenance metrics can prevent unexpected failures, ensuring uninterrupted fluid control and enhancing productivity in industrial settings. These insights illustrate the vital importance of incorporating data-driven strategies when selecting and maintaining hydraulic valves.

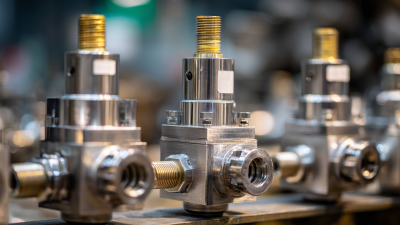

Future Trends in Hydraulic Valve Technology and Innovation

The future of hydraulic valve technology is poised for significant advancements as industries increasingly focus on optimizing efficiency and fluid control systems. By 2033, the global market for hydraulic pressure reduction valves is expected to grow from $770 million in 2025 to $1.16 billion, reflecting a compound annual growth rate of 5.2%. This trend underscores the increasing reliance on hydraulic systems across various sectors, leading to innovations that enhance the performance, reliability, and sustainability of these critical components.

Moreover, as the automotive industry experiences transformative changes, the integration of advanced hydraulic systems in vehicles, particularly in active suspension systems, is gaining momentum. With the market size projected to rise from $286.53 million in 2025 to $530.74 million by 2033, it is evident that hydraulic valves will play a pivotal role in the development of new technologies. This transition highlights the industry's commitment to embracing innovation, ultimately driving advancements in hydraulic valve design and functionality.

Related Posts

-

Understanding Types of Hydraulic Valves and How to Choose the Right One for Your Needs

-

Exploring the Unique Features and Applications of Various Hydraulic Valve Types

-

How to Choose the Best Hydraulic Valves for Your Industrial Applications

-

The Future of Best Hydraulic Valves Innovations Shaping Global Manufacturing

-

Essential Tips for Selecting Top Quality Fluid Power Hydraulics Suppliers: A Data-Driven Approach

-

How to Harness Hydraulic Power for Maximum Efficiency in Your Operations

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com