Fluid Power Hydraulics vs Pneumatics Key Insights for Global Buyers

In the rapidly evolving world of industrial automation, understanding the nuances of Fluid Power Hydraulics versus Pneumatics is crucial for global buyers looking to optimize their operations. As industries increasingly adopt advanced technologies to enhance productivity, the choice between these two power transmission methods can significantly impact efficiency, cost-effectiveness, and overall performance. Fluid Power Hydraulics, known for its ability to generate high force and precise control, presents distinct advantages in heavy-duty applications, while Pneumatics offers superiority in lighter tasks with its simplicity and faster response times.

Moreover, the decision-making process for global buyers involves a comprehensive evaluation of operational needs, application environments, and long-term maintenance considerations. By delving into the key insights surrounding both Fluid Power Hydraulics and Pneumatics, decision-makers can make informed choices that not only meet current demands but also align with future technological advancements. This blog aims to clarify the critical differences and applications of both systems, providing valuable guidance for those navigating this complex landscape.

Comparative Analysis of Fluid Power Systems: Hydraulics vs Pneumatics

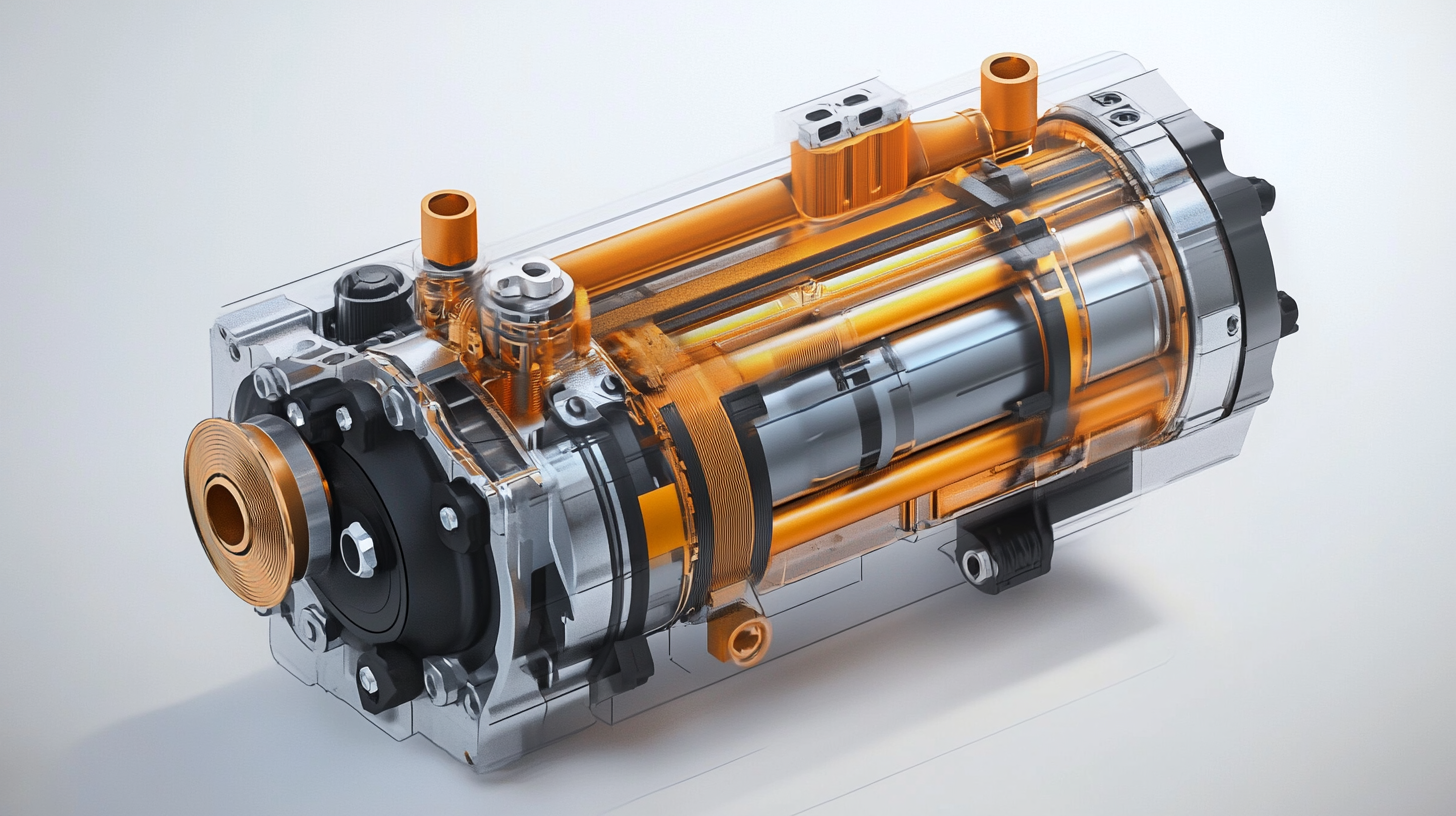

Fluid power systems play a critical role in various industrial applications, facilitating the transfer of energy through liquids or gases. Within this realm, hydraulics and pneumatics stand out as the two primary technologies. Each system has distinct advantages and limitations, making them suitable for different uses. Hydraulics, which utilize incompressible fluids, are renowned for their ability to generate high force in confined spaces. This makes them ideal for tasks requiring precision and power, such as in heavy machinery and automotive applications. The fluid’s incompressibility ensures consistent force delivery, granting operators added control in demanding environments. On the other hand, pneumatics operates on compressed gases, typically air, offering unique benefits such as lighter weight components and faster operation. These systems excel in applications requiring quick movements, such as packaging and assembly lines. However, the compressibility of gases can lead to energy loss, making pneumatics less suited for high-pressure tasks compared to hydraulics. Additionally, the maintenance of pneumatic systems might be slightly less complex since they often involve fewer parts and operate at lower pressures, reducing the likelihood of leaks, which are a common concern in hydraulic systems. Ultimately, the choice between hydraulics and pneumatics largely depends on the specific requirements of the application. Factors such as force, speed, precision, and operational environment should guide decision-makers in selecting the most efficient fluid power system that meets their operational needs. Understanding the fundamental differences between these technologies can help global buyers make informed purchasing decisions and optimize their production processes.

Key Applications of Hydraulics in Various Industries

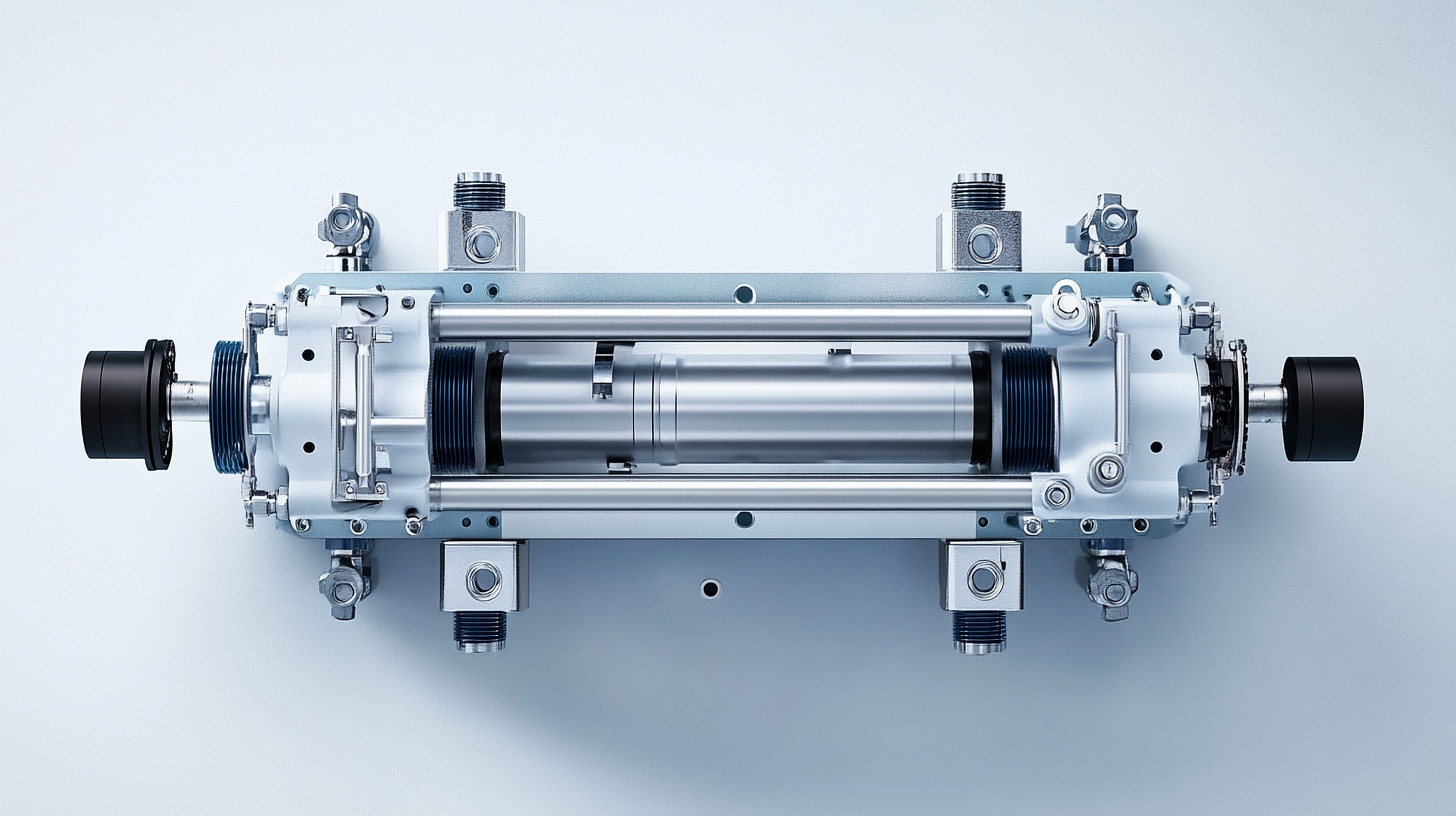

Fluid power systems, particularly hydraulics and pneumatics, play a pivotal role in a variety of industries, enabling efficiency and power in operations. Hydraulics is especially favored in applications requiring high force and precision, making it ideal for sectors such as construction and manufacturing. According to a recent report by ResearchAndMarkets, the global hydraulic machinery market is projected to reach approximately $70 billion by 2026, fueled by the increasing demand in sectors like agriculture, where hydraulic systems are vital for operating machinery such as tractors and plows.

In the aerospace industry, hydraulic systems are critical for flight control systems. A report from MarketsandMarkets highlights that the aerospace hydraulic systems market is expected to grow from $5.56 billion in 2021 to $8.12 billion by 2026, illustrating the essential role of hydraulics in enhancing aircraft performance and safety. This growth is attributed to the demand for lightweight, high-performance components that efficiently handle the forces experienced during flight.

Moreover, the automotive industry extensively utilizes hydraulic systems for braking and steering mechanisms, ensuring safety and performance. Statistics indicate that over 90% of vehicles on the road today utilize hydraulic braking systems, according to a study by the International Journal of Automotive Technology. As manufacturers continue to focus on innovation and sustainability, the integration of advanced hydraulic technologies will drive further improvements in vehicle efficiency and safety standards.

Advantages and Limitations of Pneumatic Systems

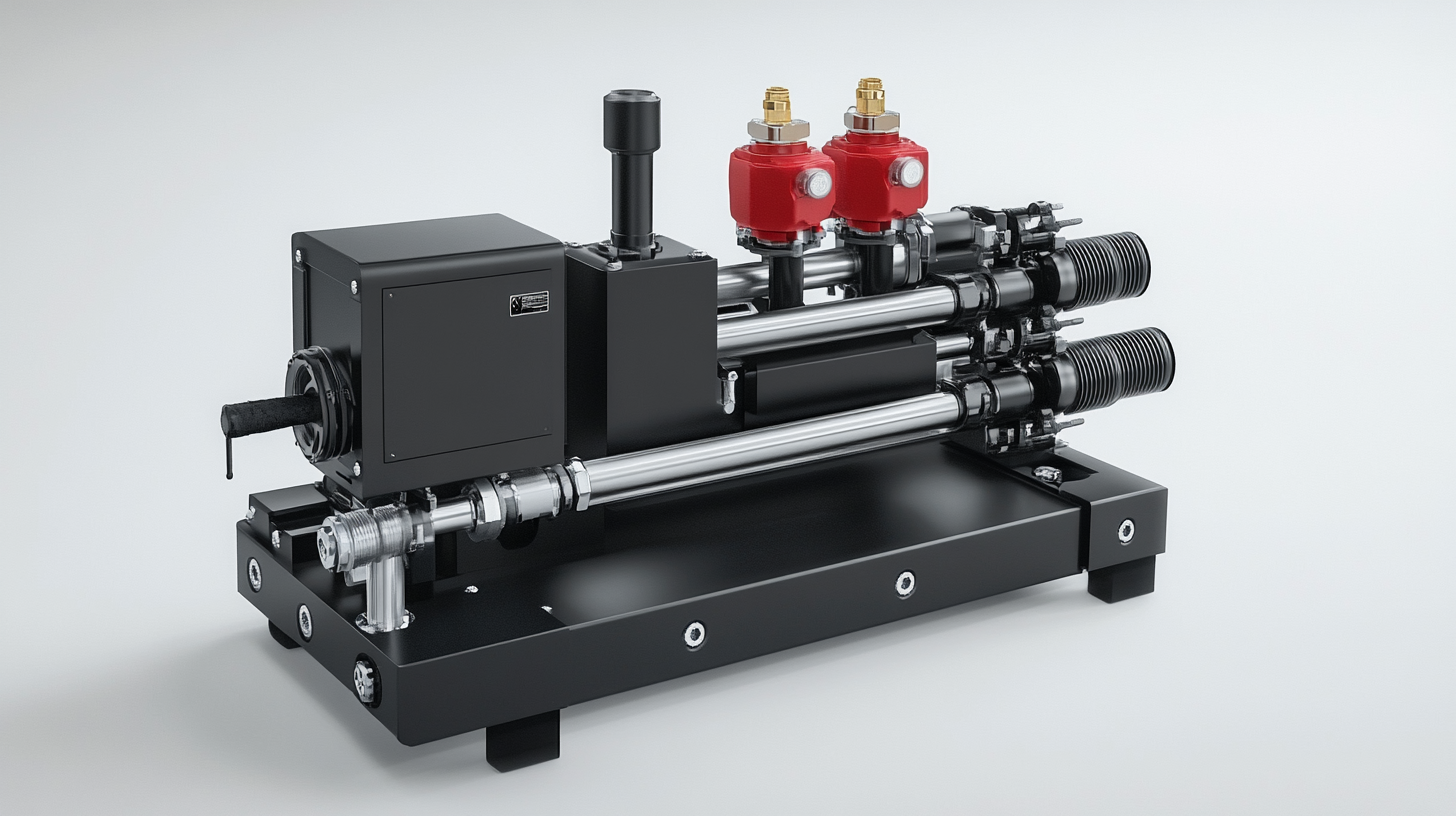

Pneumatic systems have gained significant attention in various industries due to their unique advantages and limitations. One of the primary benefits of pneumatics is their ability to provide rapid actuation. Pneumatic actuators can move quickly, making them ideal for applications where speed is critical, such as in assembly lines and robotic systems. Their lightweight and compact nature also contributes to their efficiency, allowing for the design of more flexible and versatile machinery.

However, despite these advantages, pneumatic systems come with inherent limitations. One such drawback is their reliance on compressed air, which can lead to energy inefficiencies. The production and maintenance of compressed air systems require considerable energy input, which can be a disadvantage in energy-sensitive environments. Additionally, pneumatic systems are generally less precise than their hydraulic counterparts. The compressibility of air can result in less accurate control, particularly in applications that require fine movements or high forces.

Moreover, the performance of pneumatic systems can be affected by environmental factors, such as temperature and humidity. Changes in these conditions can alter the density of the air, impacting the effectiveness of the system. As industries continue to innovate and refine pneumatic technology, understanding these advantages and limitations is crucial for global buyers looking to implement pneumatic solutions in their operations.

Cost Considerations for Global Buyers in Fluid Power Solutions

When considering fluid power solutions, buyers must navigate the cost implications of hydraulics and pneumatics. Each system offers distinct advantages and drawbacks, significantly impacting the overall budget and operational efficiency. Hydraulics provide high power density and controllable force, making them suitable for heavy-duty applications. However, they often come with higher maintenance costs and initial investment. On the other hand, pneumatic systems cost less upfront and are simpler to maintain, making them attractive for applications requiring lighter loads and quick motion.

Recent developments in the market indicate a heightened competition among distributors, highlighting the importance of selecting partners who can provide not just quality products but also value-added services. For instance, one distributor recently received notable recognition for excellence, underscoring the need for buyers to consider the reputation and reliability of their suppliers. This focus on partnership can lead to more competitive pricing, improved service options, and better access to innovative technologies.

As global buyers evaluate their fluid power needs, it's paramount to weigh initial costs alongside long-term operational efficiencies. Investing in the right technology, tailored to specific application requirements, can ultimately lead to better returns and sustained competitive advantages in their respective industries.

Future Trends in Fluid Power Technology: What to Expect

The fluid power industry is poised for significant transformation as we look towards the future. With increasing interest in data and connectivity, the industry is experiencing a shift that integrates advanced technologies into the traditional realms of hydraulics and pneumatics. These developments are not only enhancing operational efficiency but are also paving the way for smarter and more sustainable machines. The growing importance of data analysis and connectivity solutions is driving innovation, allowing for better monitoring and control of fluid systems, ultimately leading to increased performance.

As we prepare for events like PACK EXPO 2024, the latest fluid power and electromechanical motion control technologies will take center stage. Exhibitors are expected to showcase cutting-edge solutions that cater to the evolving demands of packaging and processing machinery. This convergence of fluid power and modern technologies reflects a broader trend within the industry, highlighting advancements in sensor technology and automation that enhance system capabilities.

Despite the rise of electric alternatives, there remains a positive sentiment for hydraulics and pneumatics. As the market adapts to potential economic slowdowns, the demand for hydraulic valves and mobile hydraulics is projected to grow, underscoring the resilience of the fluid power sector. Integrating those technologies with electric systems will be critical in meeting the increasing efficiency and performance needs, ensuring that the fluid power industry continues to thrive amidst competition from electrification initiatives.

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com