How to Maximize the Lifespan of Your Cylinder with Effective Repair Techniques

In the ever-evolving world of machinery and equipment, the longevity of cylinders is crucial for maintaining operational efficiency and reducing costs. As critical components in various applications, cylinders are subject to wear and tear, making effective Cylinder Repair techniques essential for maximizing their lifespan. This blog will delve into innovative repair solutions that not only restore functionality but also enhance the durability of cylinders. By understanding the underlying causes of wear and implementing proactive repair strategies, you can significantly extend the life of your cylinders, ultimately driving productivity and ensuring smooth operations. Join us as we explore practical tips and expert insights that will empower you to tackle cylinder repair challenges head-on and achieve lasting results.

Best Practices for Regular Maintenance to Extend Cylinder Life

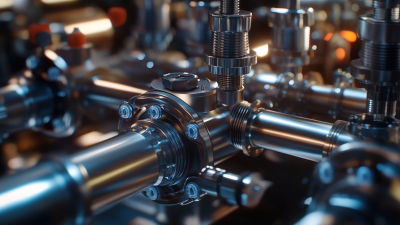

Regular maintenance is crucial for ensuring the longevity of your cylinders. One of the best practices is to perform regular inspections to identify wear and tear early. Check for any signs of leakage or corrosion, as these can lead to bigger issues down the line. Keeping the cylinder clean is equally important. Accumulated dirt and debris can cause malfunctions, so a routine cleaning schedule, using appropriate solvents that won’t harm the cylinder material, should be established.

Additionally, proper lubrication is a key component of cylinder maintenance. Ensure that lubricants are used as specified by the manufacturer to reduce friction and prevent overheating. It’s also vital to monitor operating conditions. Keeping cylinders within recommended pressure and temperature ranges minimizes stress and extends their lifespan. Furthermore, training operators on the correct handling and usage of cylinders can significantly reduce the risk of accidents and premature wear. By adhering to these best practices, you can effectively extend the service life of your cylinders and maintain optimal performance.

Identifying Common Cylinder Wear and Damage Issues

Cylinder wear and damage are critical issues that can significantly affect engine performance and longevity. According to industry reports, up to 30% of engine failures are attributable to cylinder-related problems, such as wear from insufficient lubrication, misalignment, and overheating. One common sign of cylinder wear is the presence of smoke; specifically, blue smoke often indicates oil burning, which can be a result of worn piston rings or cylinder walls.

Effective repair techniques can be employed to address these issues before they escalate. Techniques such as honing the cylinder walls to restore a proper surface finish, or using advanced sealants, can help improve oil retention and reduce blow-by. Furthermore, implementing regular inspections can mitigate risks. It has been observed that proactive maintenance practices can extend the lifespan of cylinders by up to 25%. Understanding the common wear patterns—like scoring, scratching, or pitting—allows technicians to diagnose problems early, thereby preventing costly engine failures that can stem from neglected cylinder maintenance.

Step-by-Step Guide to Effective Cylinder Repair Techniques

To maximize the lifespan of your cylinder, it is crucial to employ effective repair techniques. Proper maintenance not only extends the life of the cylinder but also enhances its performance. Begin by thoroughly inspecting the cylinder for any signs of wear or damage, such as cracks or corrosion. Catching these issues early can save you time and money in the long run.

One essential tip is to clean the cylinder regularly. Use a suitable cleaning agent to remove any build-up and contaminants that may affect its functionality. Following this, ensure you check the seals and gaskets for integrity. Replacing worn-out components can significantly prevent leaks and enhance the cylinder’s durability.

Additionally, consider implementing pressure testing as part of your repair routine. This process allows you to identify any weaknesses in the cylinder’s structure before they become serious problems. Utilizing precision instruments for measurement can help in making informed adjustments and repairs to maintain optimal performance. By following these effective cylinder repair techniques, you can ensure your cylinder remains in good working condition for years to come.

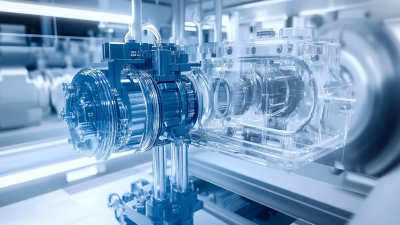

Choosing the Right Tools and Materials for Cylinder Restoration

When it comes to cylinder restoration, selecting the right tools and materials can significantly impact the longevity and efficiency of your repairs. High-quality tools are essential for precise extraction and insertion processes. Consider using specialty wrenches and torque tools that match the specifications of your cylinder. This will help you avoid damaging components during the repair and ensure a secure reassembly.

In addition to tools, the materials you choose are equally important. Opt for OEM (Original Equipment Manufacturer) parts and seals, as they are specifically designed for compatibility and durability. When it comes to the restoration of the cylinder surface, using appropriate sealants and lubricants can enhance performance and longevity. Choose products that resist wear and corrosion, as these factors often lead to premature failure.

Tip 1: Regularly inspect your tools for wear and replace them as necessary to maintain high efficiency in your repair work.

Tip 2: Always adhere to manufacturer guidelines when selecting materials, as deviations can lead to complications or failures. By focusing on quality and compatibility, your cylinder can enjoy an extended lifespan.

Tips for Preventing Future Damage and Enhancing Performance

To enhance the performance and lifespan of your cylinder, it's essential to implement effective preventive strategies. Regular maintenance plays a vital role in preventing future damage. Start by conducting routine inspections to check for any signs of wear or leaks. Addressing minor issues before they escalate can save you time and money in the long run. Keeping your cylinder clean and free from contaminants will also help maintain its efficiency. Consider using suitable lubricants and cleaning agents that are compatible with your cylinder's materials.

In addition to maintenance, the way you operate the cylinder can significantly impact its longevity. Always follow the manufacturer’s guidelines regarding load limits and operational practices. Avoid overloading or pushing the cylinder beyond its intended capacity. This will not only prevent unnecessary stress on the components but also enhance overall performance. Implementing these practices will ensure that your cylinder operates smoothly, providing reliable service for years to come.

How to Maximize the Lifespan of Your Cylinder with Effective Repair Techniques - Tips for Preventing Future Damage and Enhancing Performance

| Repair Technique | Benefits | Potential Risks | Recommended Frequency |

|---|---|---|---|

| Regular Inspection | Early detection of issues | Neglecting minor repairs can escalate | Monthly |

| Lubrication | Reduces friction, enhances performance | Over-lubrication can cause buildup | Every 500 hours of operation |

| Sealing Replacement | Prevents leaks and pressure loss | Incorrect installation can lead to issues | Annual |

| Cleaning | Improves efficiency, prevents corrosion | Inadequate cleaning can damage components | Every 250 hours of operation |

| Pressure Testing | Ensures structural integrity | Risk of failure if not conducted properly | Bi-annual |

Related Posts

-

Highlighting Cylinder Repair Innovations at the 137th Canton Fair in Guangzhou

-

Ultimate Guide to Choosing the Best Cylinder Repair Solutions for Your Needs

-

Innovative Approaches for Optimal Hydraulic System Efficiency

-

2025 Industry Tech Trends: How Best High Pressure Hoses Are Revolutionizing Efficiency and Safety

-

Exploring the Unique Features and Applications of Various Hydraulic Valve Types

-

Comprehensive Handbook to Mastering Hydraulic Equipment Repair for Global Buyers

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com