What is a Slitter Cutter Machine and How Does It Work?

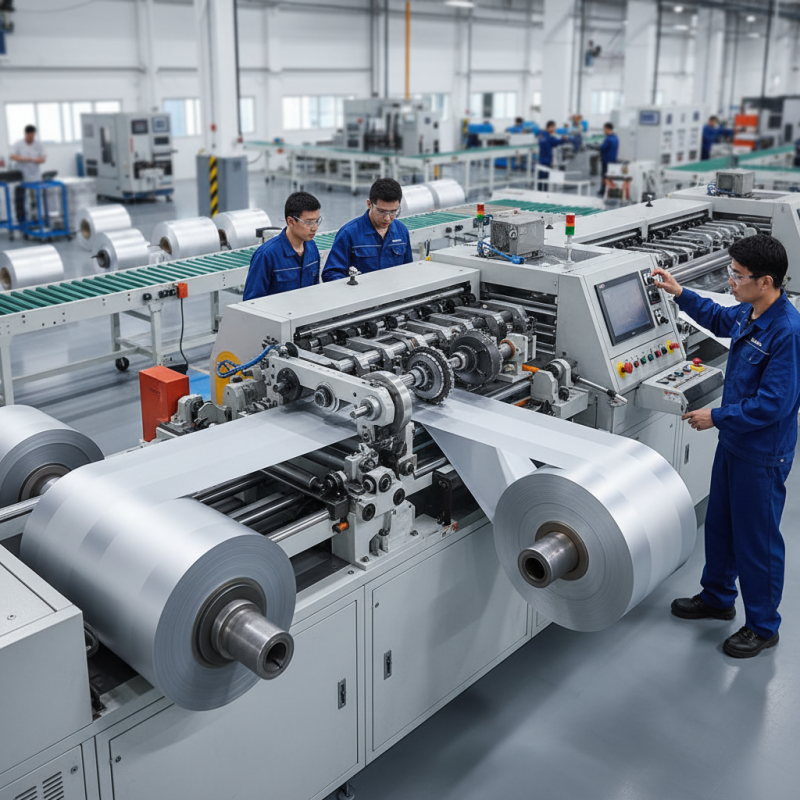

In the fast-paced manufacturing world, the Slitter Cutter Machine plays a vital role. This machine is designed to cut large rolls of material into narrower strips. Whether it's paper, plastic, or metal, the slitter cutter ensures precision and efficiency in production lines.

John Smith, an industry expert, once stated, "The Slitter Cutter Machine is essential for optimizing material use." His insight highlights the importance of this machine in reducing waste. Manufacturers strive for perfection, but challenges remain. Operators may face issues like improper blade alignment or inconsistent tension, which can lead to wasted material.

The intricacies of the Slitter Cutter Machine require knowledge and experience. Understanding how it works is crucial for improving output quality. Many professionals still seek ways to refine their techniques. The balance of efficiency and quality is an ongoing pursuit in this industry. As technology advances, the future of slitting processes will continue to evolve.

Understanding the Basics of Slitter Cutter Machines

Slitter cutter machines are essential in various manufacturing processes. They are primarily used to cut large rolls of material into narrower strips. These machines can handle different materials, including paper, plastic, and metal. Understanding their mechanics is crucial for optimizing production and ensuring quality.

The basic operation of a slitter cutter machine involves feeding a roll of material into the machine. Sharp blades slice the material into desired widths. Adjustments can be made to accommodate different thicknesses and materials. Often, improper setup can lead to uneven cuts or waste. Regular maintenance is critical to avoid these issues.

Operators must be attentive during the cutting process. Even minor distractions can result in defects. Visual inspection of the cuts ensures quality control. Additionally, training is vital for effective operation. Learning about the machine's features can improve efficiency. However, not all operators grasp these concepts quickly, leading to mistakes. Continued education in this area reflects the importance of mastering the basics.

Slitter Cutter Machine Production Efficiency

This chart showcases the production efficiency of slitter cutter machines over a six-month period. The data indicates a consistent improvement in efficiency, peaking in June.

Historical Development of Slitter Cutter Technology

The slitter cutter machine has an interesting history. Its roots can be traced back to the early 20th century. Initially, it was used in the paper industry. The need for precision and efficiency drove innovations. Manufacturers sought ways to cut materials into various widths, paving the way for new designs.

By the 1950s, slitter technology evolved significantly. Factories began adopting automated models. These devices improved production speed and reduced waste. However, early machines had limitations. They often struggled with thicker materials and uneven cuts. This highlighted a need for further upgrades.

As industries grew, so did the demands for advanced slitting techniques. New materials emerged, challenging existing designs. Engineers faced obstacles in meeting these demands. Continuous improvements have led to the development of specialized machines. Today’s slitter cutters are more versatile and efficient. Yet, challenges remain, prompting ongoing innovation in the field.

What is a Slitter Cutter Machine and How Does It Work? - Historical Development of Slitter Cutter Technology

| Dimension | Details |

|---|---|

| Machine Type | Slitter Cutter Machine |

| Main Function | Cutting and slitting materials |

| Common Materials | Paper, film, plastic, metal |

| Cutting Mechanism | Rotary blades or knives |

| Historical Origin | Early 20th century advancements in material processing |

| Industry Applications | Printing, packaging, textiles, automotive |

| Modern Features | Automated controls, variable speed settings, precision cutting |

| Maintenance Tips | Regular cleaning, blade sharpening, lubrication |

Components and Functionality of a Slitter Cutter Machine

A slitter cutter machine is essential in various industries for slicing materials like paper, plastic, and metal. Key components include rotary knives, shafts, and tension control systems. The rotary knives are sharpened blades that accurately cut materials to desired widths. They are the heart of the machine. Shafts hold the knives in place, ensuring stability during operation. Tension control mechanisms maintain the right tension on the web materials. This balance helps to avoid curling or tearing.

In recent reports, the global slitter machine market has shown a significant growth trend. For instance, the market is expected to reach a valuation of approximately $200 million by 2025. This growth highlights the increasing demand for efficient cutting solutions in manufacturing. Despite advancements, challenges exist. Blade wear and misalignment can lead to production waste. It's a critical area for continuous improvement. Calibration and periodic maintenance are essential. Ensuring proper alignment can prevent costly delays.

Automation features in modern slitting machines are becoming standard. They enhance precision and speed, which helps meet market demands. However, operators must be well-trained. Misunderstandings in using technology can lead to errors. This reality prompts the industry to focus on training programs. Incorporating better operational practices can improve efficiency.

Applications of Slitter Cutter Machines in Various Industries

Slitter cutter machines play a crucial role in various industries. They are primarily used to cut large rolls of material into smaller, more manageable sizes. This process is essential for creating strips of paper, film, metal, or textiles. In the packaging industry, slitter cutter machines help produce packaging materials efficiently. They ensure that materials are the right size for different products, enhancing production flow.

In the textile industry, slitting machines cut fabric into desired widths. This is vital for clothing manufacturers who need specific sizes for their garments. The precision of slitter cutter machines ensures minimal waste. However, poor maintenance can lead to inconsistent cuts. Regular checks on blade sharpness can significantly improve performance.

Moreover, the use of slitter cutter machines in the automotive sector is noteworthy. They help in cutting materials like rubber and plastic for components. In this case, any error in cutting can impact the final product. It's essential to calibrate the machines properly. With the right adjustments, manufacturers can avoid costly mistakes while improving efficiency. These machines are indispensable yet often require careful handling.

Performance Metrics and Efficiency of Slitter Cutter Operations

The performance metrics of slitter cutter machines are critical to various industries. Efficiency is key, as it directly impacts production costs. According to a recent industry report, slitting operations can achieve speeds of up to 600 meters per minute. However, this efficiency can be compromised by material quality and machine maintenance.

Availability is another important metric. Many companies report downtime issues due to improper calibration or wear and tear. Studies suggest that faulty blades lead to a 15% reduction in productivity. Additionally, machine setup time plays a significant role. Reducing setup time by just 10% can enhance overall efficiency by 5% to 10%. In contrast, not addressing these challenges can result in increased operational costs.

Monitoring machine performance continuously is essential. It can help identify areas of improvement. Regular audits of slitting operations are necessary, but often overlooked. There is a tendency to focus on immediate outputs rather than long-term integrity. Ignoring minor inefficiencies can lead to significant losses over time. Integrating real-time data analytics can provide insights but is frequently underutilized.

Article Source:

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com