5 Top Hydraulic Components for Efficient Operations in 2023: Boost Your Procurement Strategy

The demand for hydraulic components has been steadily increasing, driven by their critical role in enhancing the efficiency and reliability of various industrial operations. According to a recent report by MarketsandMarkets, the global hydraulic components market is projected to reach USD 61.7 billion by 2025, growing at a CAGR of 5.2% from 2020. This growth is largely attributed to the rising adoption of hydraulic systems across sectors such as construction, agriculture, and manufacturing, where precision and power are paramount. However, despite their advantages, businesses often face challenges related to maintenance, costs, and compatibility of hydraulic components. Addressing these issues is essential for optimizing procurement strategies and ensuring seamless operations. In this blog, we will highlight the top five hydraulic components for 2023 that not only meet industrial demands but also resolve common operational problems, guiding your procurement decisions effectively.

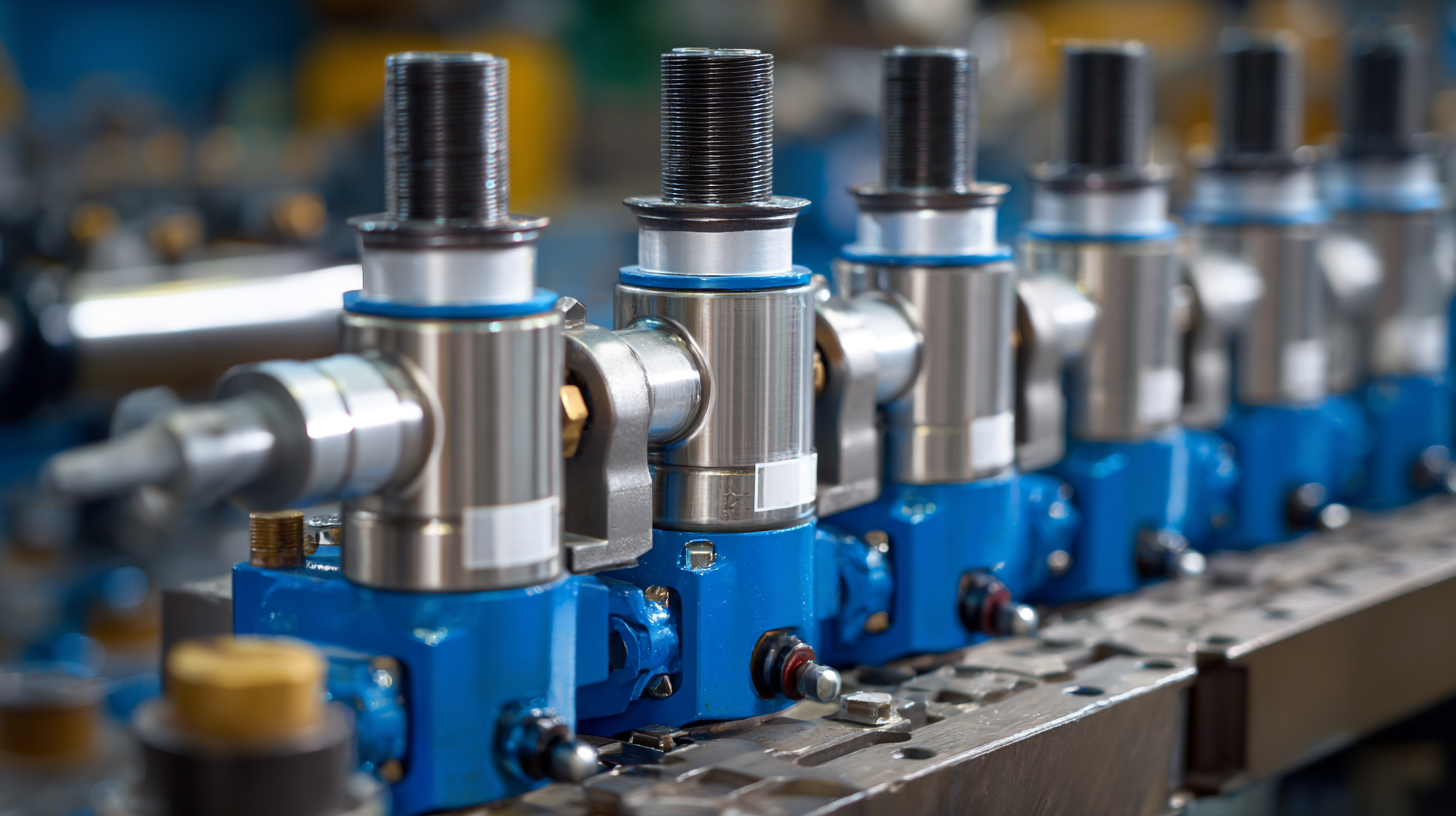

Key Hydraulic Components Essential for Modern Industrial Applications

In the fast-evolving landscape of industrial applications, the significance of key hydraulic components cannot be overstated. The global hydraulic cylinder market, which was valued at approximately USD 14.3 billion in 2021, is projected to experience robust growth, reaching an estimated USD 18.3 billion by 2027. This surge highlights the increasing reliance on hydraulic systems to enhance operational efficiency across various sectors, including construction, manufacturing, and agriculture.

Among the essential components for modern hydraulic systems, hydraulic cylinders, pumps, valves, and actuators stand out as pivotal to ensuring smooth and reliable operations. Hydraulic cylinders, for instance, play a crucial role in converting hydraulic energy into mechanical power, while hydraulic pumps are integral for maintaining system pressure and flow. Similarly, advanced valves enable precise control over fluid movement, thereby optimizing performance and responsiveness in industrial applications. As industries continue to prioritize automation and efficiency, understanding and investing in these hydraulic components will be crucial for procurement strategies in 2023 and beyond.

Understanding Hydraulic Component Certifications and Regulatory Standards

When selecting hydraulic components in 2023, understanding certifications and regulatory standards is critical for ensuring efficiency and safety in operations. Regulations vary by region, and staying updated on these guidelines is essential for compliance. Components must meet specific quality standards, such as ISO and SAE certifications, which guarantee reliability and performance. Familiarizing your procurement team with these certifications can prevent costly issues down the line.

Tip: When sourcing hydraulic components, always verify their certifications. Request documentation that proves compliance with industry standards to ensure that your chosen components will perform optimally and safely.

In addition to seeking certified products, it is beneficial to stay informed about any upcoming changes in regulations. This proactive approach allows you to adapt your procurement strategy swiftly and avoid disruptions in your supply chain. Engaging with suppliers who are knowledgeable about industry standards can also provide valuable insights into emerging trends that may impact your operations.

Tip: Attend industry seminars and workshops focused on hydraulic systems to gain a deeper understanding of regulations and network with experts in the field. This can enhance your procurement strategy by ensuring you are well-informed about the latest compliance requirements.

Best Practices for Sourcing Quality Hydraulic Parts Globally

In 2023, global procurement strategies for hydraulic components have become increasingly intricate, requiring a focus on quality and efficiency. According to a recent report by MarketsandMarkets, the hydraulic equipment market is projected to reach $65 billion by 2026, with a compound annual growth rate (CAGR) of 5.8%. This growth underscores the importance of sourcing high-quality hydraulic parts to sustain operational reliability and enhance machinery performance. As industries expand and require more advanced hydraulic systems, procurement teams must prioritize partnerships with reputable suppliers that adhere to stringent quality standards.

Best practices for sourcing hydraulic parts globally include conducting thorough supplier assessments, leveraging digital procurement platforms, and implementing strategic relationships. A study from Deloitte highlights that organizations with effective supply chain strategies can reduce procurement costs by up to 20%. Additionally, focusing on suppliers with certifications like ISO 9001 can further guarantee that the hydraulic components meet industry standards. Collaborating with global suppliers not only broadens the choice of quality parts but also helps mitigate risks associated with local market fluctuations, ensuring efficient operations across various sectors.

Top 5 Hydraulic Components for Efficient Operations in 2023

This chart represents the demand for the top 5 hydraulic components in 2023, showcasing their importance for efficient operations.

Leveraging Technology for Efficient Hydraulic Systems Procurement

In the rapidly evolving landscape of hydraulic systems, leveraging technology has become paramount for enhancing procurement strategies. The integration of advanced software solutions allows procurement teams to streamline their processes, ensuring that they can source high-quality hydraulic components efficiently. By utilizing digital tools, organizations can access comprehensive databases of suppliers, compare pricing in real time, and ensure compliance with industry standards. This not only reduces lead times but also enhances decision-making through data-driven insights.

In the rapidly evolving landscape of hydraulic systems, leveraging technology has become paramount for enhancing procurement strategies. The integration of advanced software solutions allows procurement teams to streamline their processes, ensuring that they can source high-quality hydraulic components efficiently. By utilizing digital tools, organizations can access comprehensive databases of suppliers, compare pricing in real time, and ensure compliance with industry standards. This not only reduces lead times but also enhances decision-making through data-driven insights.

Moreover, predictive analytics plays a crucial role in optimizing inventory management for hydraulic components. By analyzing historical data and market trends, companies can forecast demand more accurately, minimizing stockouts and excess inventory. Automation in procurement processes, from order placements to payment processing, can further boost operational efficiency. Adopting these technological advancements enables organizations to pivot swiftly in a competitive market, ensuring that their operations remain effective and cost-efficient. Embracing these innovations positions businesses to thrive as they redefine their procurement strategies for hydraulic systems in 2023 and beyond.

Cost-Effective Strategies for Maintaining Hydraulic Component Efficiency

In today's competitive landscape, maintaining the efficiency of hydraulic components is essential for operational success. Implementing cost-effective strategies can significantly enhance performance while minimizing expenditures. One key tip is to conduct regular inspections and maintenance checks. This proactive approach helps identify wear and tear before they lead to costly component failures. Additionally, adhering to a scheduled maintenance regimen can extend the life of equipment, ensuring that your hydraulic systems operate efficiently throughout their lifespan.

Another effective strategy is to invest in training for your operational staff. Knowledgeable employees can better understand the intricacies of hydraulic systems, leading to quicker troubleshooting and repairs. Providing them with ongoing education about new technologies and maintenance best practices fosters a culture of efficiency and accountability. This investment not only enhances performance but can also reduce downtime, ultimately benefiting your procurement strategy by aligning operational needs with the right components at the right time.

5 Top Hydraulic Components for Efficient Operations in 2023

| Component Name | Function | Efficiency Rating | Cost ($) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Hydraulic Pump | Converts mechanical energy to hydraulic energy | 85% | 500 | 6 |

| Hydraulic Cylinder | Converts hydraulic energy to mechanical energy | 90% | 400 | 12 |

| Hydraulic Filter | Removes contaminants from hydraulic fluid | 95% | 150 | 3 |

| Hydraulic Hose | Conveys hydraulic fluid | 80% | 100 | 24 |

| Hydraulic Accumulator | Stores energy in hydraulic systems | 88% | 300 | 18 |

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com