Essential Tips for Selecting Top Quality Fluid Power Hydraulics Suppliers: A Data-Driven Approach

In the rapidly evolving field of Fluid Power Hydraulics, selecting the right supplier is critical for ensuring optimal performance and reliability in hydraulic systems. According to a recent study by the International Fluid Power Society, the global market for fluid power systems is projected to reach $58 billion by 2025, highlighting the increasing demand for quality components and services. As industries continue to integrate advanced technologies and automation, the need for top-quality hydraulics suppliers becomes paramount. A data-driven approach not only assists in identifying suppliers with the best track records but also ensures alignment with industry standards and performance metrics. By leveraging comprehensive supplier assessments, buyers can significantly reduce the risk of equipment failure and enhance operational efficiency, ultimately driving long-term success in hydraulic applications.

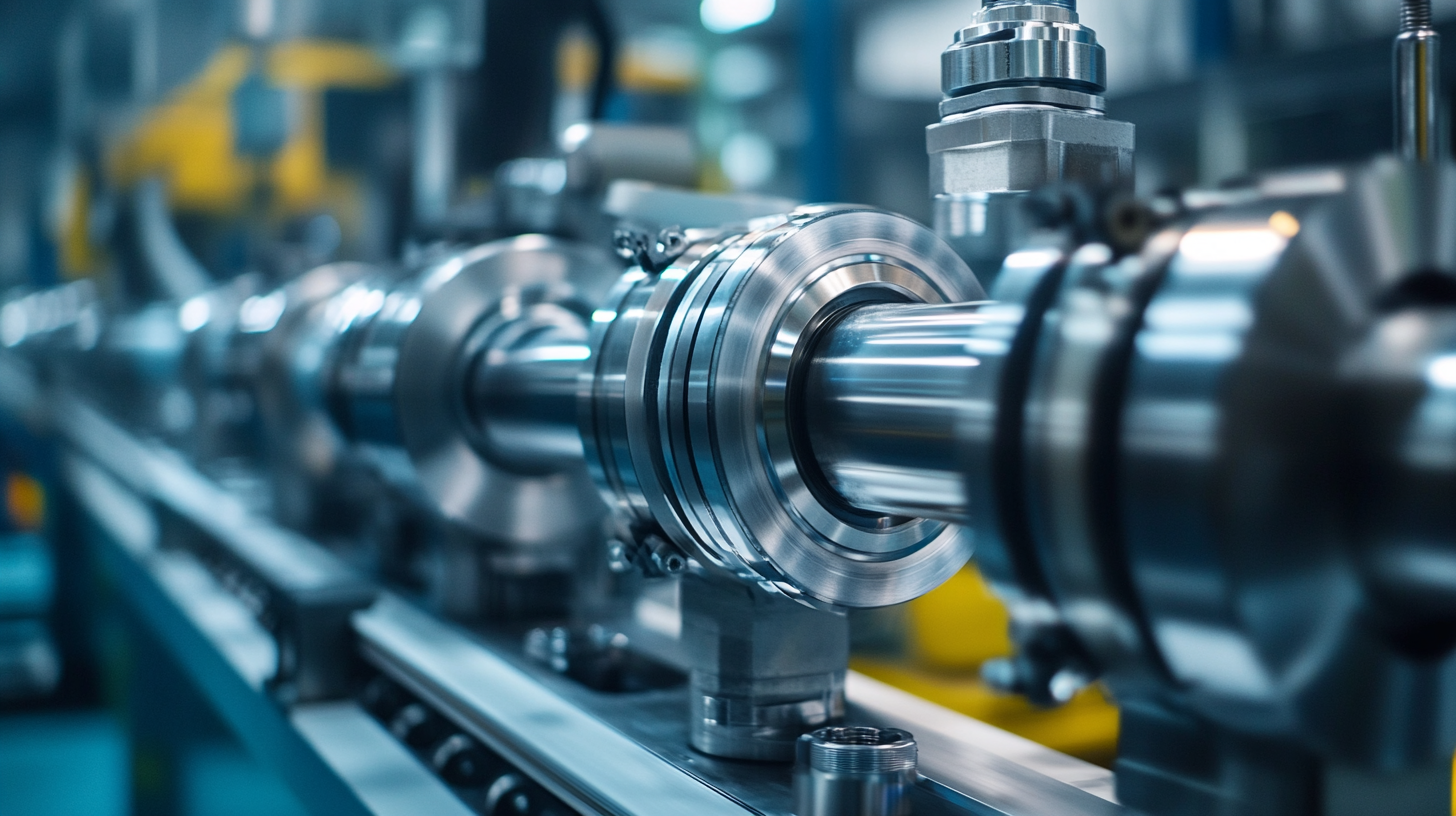

Understanding the Importance of Fluid Power Hydraulics in Industry

Fluid power hydraulics play a crucial role in various industries, significantly contributing to the efficiency and productivity of operations. As technology evolves, the applications of hydraulic systems expand beyond traditional realms, impacting sectors such as food production, construction, and mobile machinery. The growing complexity of these systems necessitates a deeper understanding of their maintenance and operational importance, ensuring optimal performance and safety across all applications.

With advancements in automation and electrification, the fluid power industry is adapting to meet the diverse needs of modern engineering roles. Although there is a high demand for skilled engineers in this field, challenges remain in filling these crucial positions. A focus on preventative and predictive maintenance is vital not only to extend the lifespan of hydraulic systems but also to mitigate potential risks associated with system failures. As the industry prepares for future developments, staying informed about these trends will enable organizations to harness the full potential of hydraulic technology effectively.

Quality Assessment of Fluid Power Hydraulics Suppliers

This bar chart represents the quality scores of various fluid power hydraulics suppliers based on key assessment criteria. High-quality suppliers are essential for ensuring efficiency and reliability in industrial applications.

Key Criteria for Assessing the Quality of Hydraulics Suppliers

When selecting a top-quality fluid power hydraulics supplier, it is essential to assess various key criteria that ensure the supplier meets high standards of performance and reliability. One of the most crucial factors to consider is the supplier's experience and expertise in the industry. A supplier with a long-standing history and proven track record can provide valuable insights and reliability, similar to how established manufacturers draw on decades of experience in vehicle production to offer exceptional quality.

Another important criterion is the supplier’s commitment to continuous improvement and adherence to stringent quality standards. This may involve embracing advanced manufacturing techniques and quality control processes to ensure that their hydraulics components are not only innovative but also reliable and durable. Suppliers that invest in quality assurance demonstrate their dedication to empowering users through superior product performance, which is pivotal in maintaining competitive advantage in the ever-evolving market.

Additionally, evaluating customer support and service is vital. A responsive supplier that provides comprehensive support can significantly influence a company’s operational efficiency. By focusing on these criteria, businesses can make informed decisions that lead to partnerships with suppliers who not only meet the immediate needs but also contribute positively to long-term success.

Essential Tips for Selecting Top Quality Fluid Power Hydraulics Suppliers

Leveraging Data Analytics for Supplier Performance Evaluation

In today's competitive landscape, the importance of leveraging data analytics for supplier performance evaluation in the fluid power hydraulics sector cannot be overstated. According to a report by MarketsandMarkets, the global hydraulic equipment market is projected to reach $66.7 billion by 2025, with a significant portion of this growth driven by advancements in data analytics and technology integration. Companies must adopt a data-driven approach to assess potential suppliers effectively, ensuring they meet quality standards and can contribute positively to the supply chain.

The use of key performance indicators (KPIs) is crucial in this evaluation process. Metrics such as on-time delivery rates, defect rates, and overall equipment effectiveness (OEE) provide a measurable framework for assessing supplier reliability. A study from the Institute for Supply Management revealed that organizations utilizing data analytics to evaluate supplier performance improved their procurement efficiency by up to 20%. By analyzing these metrics over time, companies can identify trends, anticipate potential issues, and make informed decisions about supplier selection.

Furthermore, incorporating predictive analytics into the supplier evaluation process enables businesses to forecast supplier capabilities and risks. A report by Gartner highlighted that organizations employing predictive analytics in their supply chain operations saw a 25% increase in their ability to manage risks effectively. This approach not only aids in supplier selection but also fosters long-term partnerships and sustainable growth in the fluid power hydraulics industry.

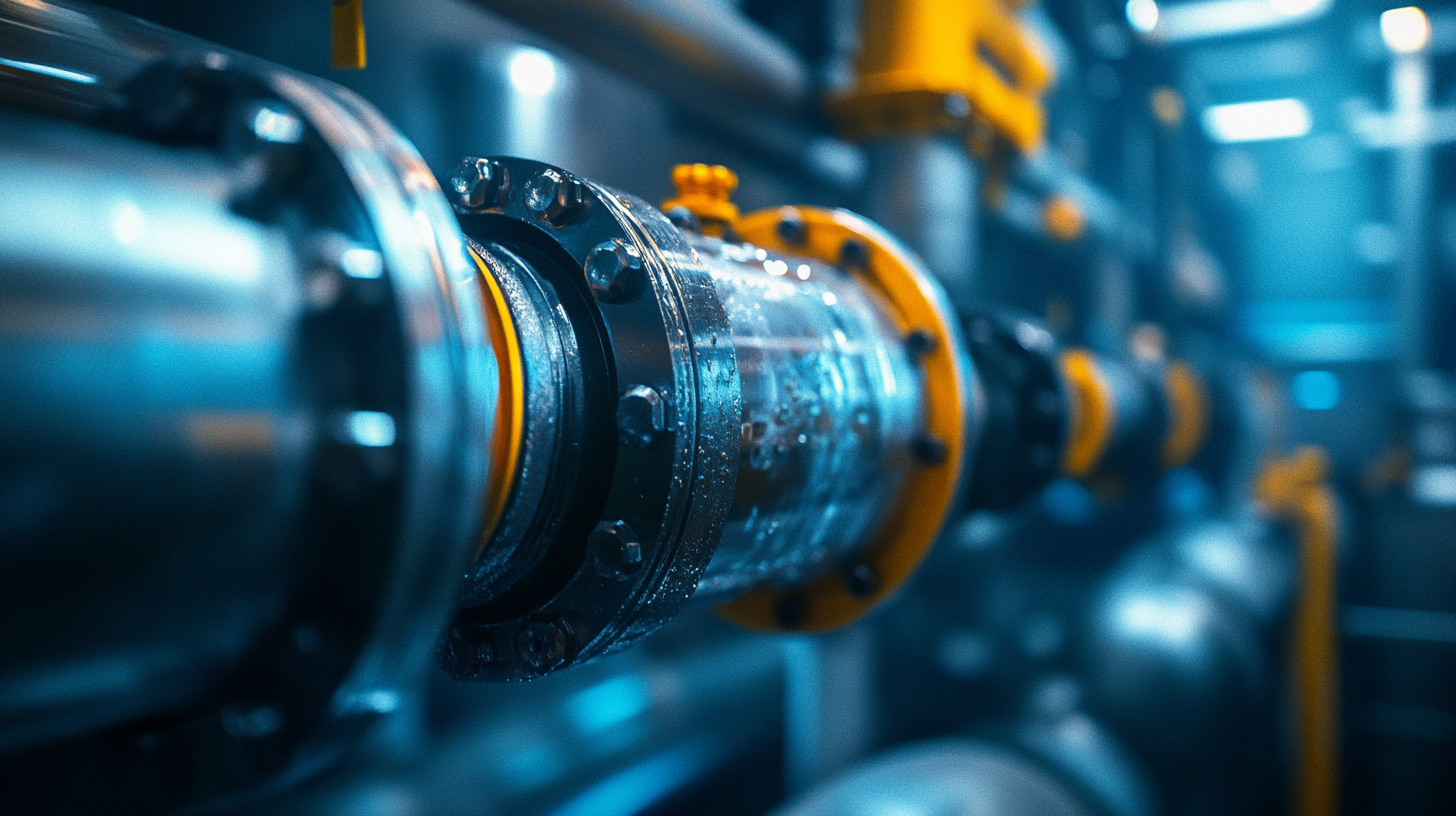

Building Long-Term Relationships with Reliable Hydraulics Suppliers

When selecting a hydraulics supplier, building a long-term relationship is paramount. According to a report by the Fluid Power Society, companies that foster strong partnerships with their hydraulic suppliers experience up to a 30% reduction in downtime, as reliable suppliers are more committed to urgent response and service. This commitment ensures that critical components are available when needed, minimizing disruptions in production processes.

Moreover, a study published in the Journal of Fluid Power found that companies engaging in strategic supplier relationships see up to a 20% improvement in operational efficiency. Long-term suppliers not only understand the specific needs of their customers but also are more inclined to share innovations and insights that can lead to enhanced system performance. It underscores the importance of collaboration and communication in achieving mutual goals, further solidifying the supplier-customer bond.

Investing in a reliable hydraulics supplier also means leveraging their expertise for continuous improvement. Data from a recent market analysis indicates that organizations that work closely with suppliers on product development and customization can achieve significant cost savings—estimated at 15% or more—by optimizing their hydraulic systems for specific applications. Thus, selecting the right supplier is not just a transactional decision but a strategic one that can lead to substantial long-term benefits.

Essential Tips for Selecting Top Quality Fluid Power Hydraulics Suppliers

| Supplier Name | Experience (Years) | Certification | Customer Ratings (out of 5) | Response Time (Hours) | Delivery Timeliness (%) |

|---|---|---|---|---|---|

| Hydraulic Solutions Inc. | 15 | ISO 9001 | 4.8 | 2 | 95 |

| Power Fluid Dynamics | 10 | ASME | 4.5 | 3 | 90 |

| FluidPower Innovations | 8 | ISO 13485 | 4.9 | 1 | 98 |

| Universal Hydraulics Co. | 12 | SABER | 4.3 | 4 | 85 |

Industry Trends Impacting the Fluid Power Hydraulics Market

The fluid power hydraulics market has been experiencing a turbulent period, particularly highlighted by the recent decline in hydraulic and pneumatic shipments reported in February 2025. According to the latest data from the National Fluid Power Association, shipments fell both month-over-month and year-over-year, indicating a significant slowdown in market activity. This downturn follows a brief uptick in shipments observed in October 2024, where, despite rising figures, overall trends continued a downward trajectory compared to the preceding year.

However, industry experts remain optimistic about specific segments within the market. The mobile hydraulics sector is projected to rebound, with forecasts from Interact Analysis indicating a return to growth trends in 2025 after a challenging year in 2024. This discrepancy between general shipment trends and the optimistic outlook for mobile hydraulics highlights the importance of discerning niche markets that may thrive even amidst broader economic challenges.

As businesses navigate these shifting dynamics, selecting top-quality fluid power hydraulics suppliers will be crucial. Data-driven approaches grounded in current industry trends can provide valuable insights, allowing organizations to make informed decisions in this rapidly changing landscape.

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com