Understanding Hydraulic Pistons: The Key to Efficient Energy Systems Explained

Hydraulic pistons are pivotal components in the realm of energy systems, playing a crucial role in maximizing efficiency across various applications, from manufacturing to renewable energy sectors. The global hydraulic equipment market is projected to reach $50 billion by 2025, with hydraulic systems, powered by hydraulic pistons, accounting for a significant share due to their unparalleled reliability and efficiency (Mordor Intelligence, 2022). As industries increasingly prioritize sustainability and productivity, understanding the mechanics of hydraulic pistons becomes essential. These devices not only enhance performance but also contribute to energy conservation by optimizing fluid power systems, which can improve overall energy efficiency by up to 30% (International Energy Agency, 2021). Consequently, grasping the principles behind hydraulic pistons empowers engineers and businesses to innovate and implement more effective energy solutions, ensuring a sustainable future in an ever-competitive market.

Understanding the Basics of Hydraulic Pistons and Their Role in Energy Systems

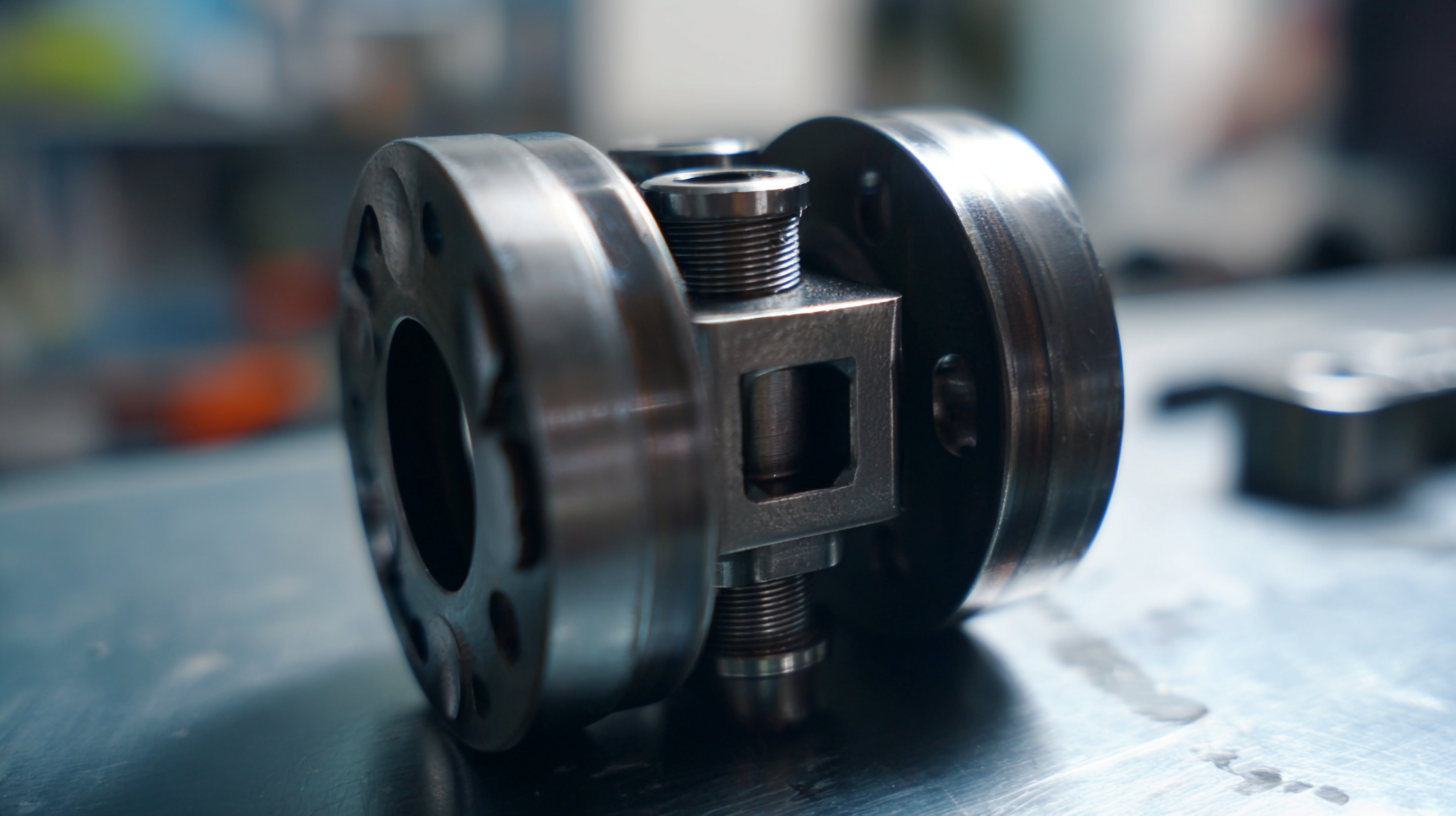

Hydraulic pistons are critical components in various energy systems, serving to convert fluid power into mechanical work. They operate on the principle of hydraulic pressure, which allows them to generate significant force with relatively minimal energy consumption. According to a report by the International Energy Agency (IEA), the use of hydraulic systems can enhance the efficiency of energy transmission by up to 30%, particularly in industrial applications where precision is essential.

These pistons play a vital role in applications ranging from construction machinery to renewable energy systems, such as hydraulic turbines. For instance, a study published in the Journal of Hydraulic Engineering reveals that hydraulic turbines can achieve efficiency rates of over 85% when integrated with well-designed hydraulic piston systems. This not only maximizes energy extraction but also minimizes operational costs, making hydraulic technology an attractive option in the fight against rising energy demands and the need for sustainable solutions. Through continuous advancements in materials and engineering practices, the future of hydraulic pistons looks promising, offering even greater efficiencies and wider applications across various sectors.

Understanding Hydraulic Pistons in Energy Systems

This bar chart illustrates key characteristics of hydraulic pistons, including their diameter, stroke length, operating pressure, force output, and efficiency levels. Understanding these metrics is crucial for enhancing the design and performance of energy systems that utilize hydraulic technology.

Exploring the Efficiency Benefits of Hydraulic Pistons in Modern Machinery

The efficiency benefits of hydraulic pistons have become increasingly significant in modern machinery, especially as industries strive to enhance productivity and operational reliability. According to recent trends, the hydraulic cylinder market is expected to witness robust growth, driven by the demand for reliable motion control solutions that support these efficiency enhancements. The integration of advanced hydraulic systems can result in improved performance characteristics and heightened operational efficiency, particularly in agricultural and construction equipment.

Recent advancements in hydraulic fluid formulations and technologies are poised to further boost the capabilities of hydraulic pistons. For instance, innovations aimed at achieving precise finishes in cylinder bores are essential for ensuring the optimal operation of hydraulic cylinders. This demand for precision is mirrored in the market where companies are replacing legacy machinery with advanced models to increase production efficiency and reduce lead times. Furthermore, the rise of electro-hydraulics is transforming the landscape, providing enhanced functionality for off-highway vehicles and supporting the future of energy-efficient machinery in diverse applications. These developments underscore the critical role hydraulic pistons play in facilitating efficient energy systems across various sectors.

Key Performance Metrics: Assessing the Energy Output of Hydraulic Pistons

Hydraulic pistons play a crucial role in modern energy systems, providing a mechanism for converting hydraulic energy into mechanical output. To assess the effectiveness of these systems, it's essential to consider key performance metrics such as force output, efficiency, and response time. A well-calibrated hydraulic piston can yield significant energy output, maximizing productivity in various applications, from manufacturing processes to renewable energy systems.

When evaluating the energy output of hydraulic pistons, consider the following tips: First, ensure proper maintenance of the hydraulic fluid and components to maintain optimum performance. Regular inspections can prevent leaks and wear, ensuring that your system operates efficiently. Secondly, calibrate the system to achieve the best possible pressure settings, as incorrect pressure can lead to suboptimal performance and energy wastage. Lastly, monitor the temperature of the hydraulic fluid, as excessive heat can degrade performance and reduce the lifespan of the components.

By focusing on these key performance metrics and tips, users can make informed decisions that enhance the efficiency of their hydraulic piston systems. Understanding these factors not only improves energy output but also contributes to the sustainability of energy systems overall.

Industry Standards and Innovations in Hydraulic Cylinder Technology

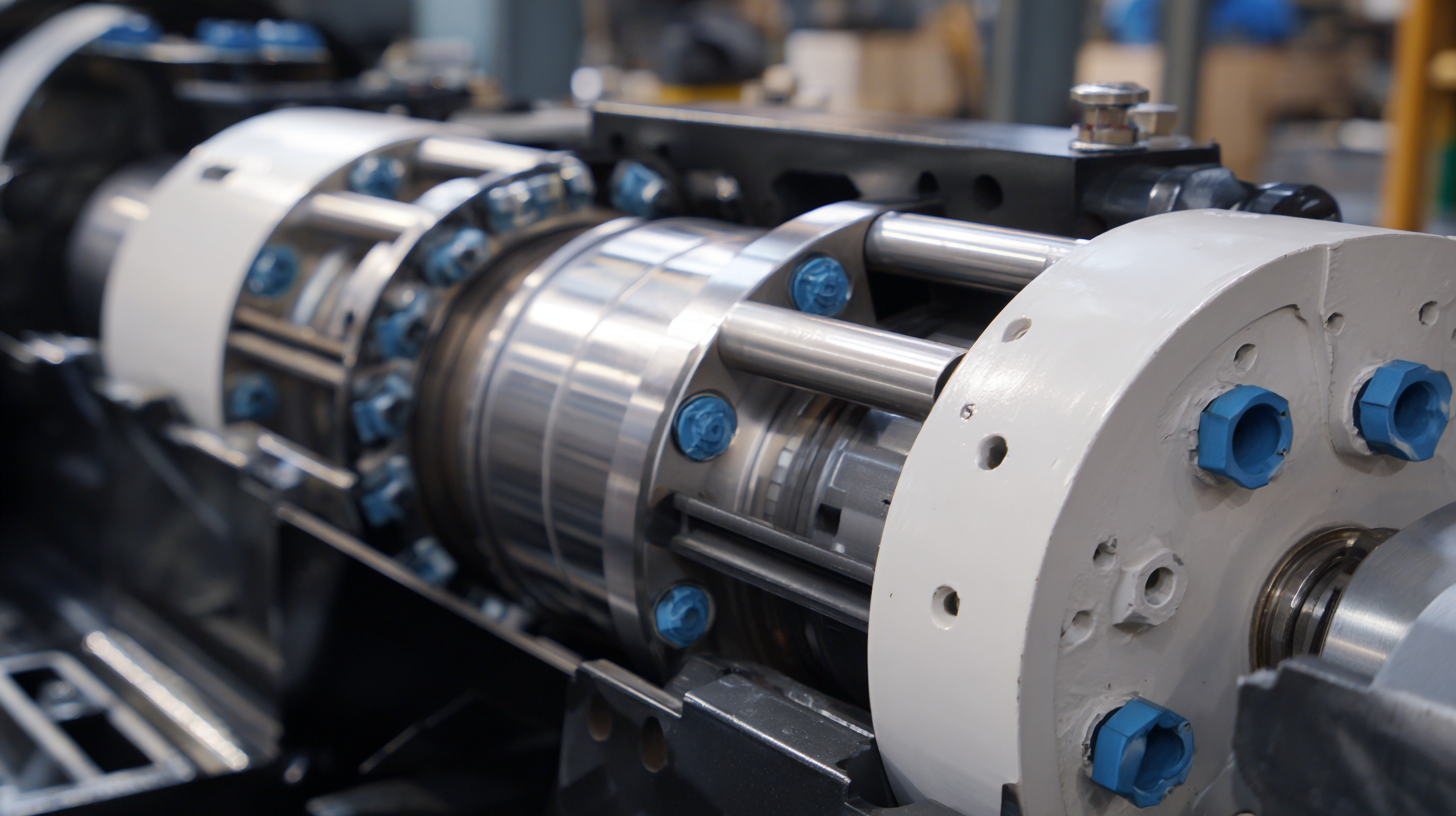

In the realm of hydraulic technology, understanding industry standards and innovations in hydraulic cylinder design is crucial for enhancing efficiency and performance in energy systems. According to the "Hydraulic Cylinder Market Size, Share & Trends Analysis Report" by Grand View Research, the global hydraulic cylinder market was valued at approximately $11.0 billion in 2022 and is projected to grow at a CAGR of 4.5% from 2023 to 2030. This growth can be attributed to advancements in materials and technology, enabling the production of lighter, more durable, and efficient cylinders.

One notable innovation is the integration of smart technology in hydraulic systems. These advancements allow for real-time monitoring and predictive maintenance, minimizing downtime and optimizing performance. Companies are increasingly adopting standards set by ISO 6020, which defines the dimensional and performance requirements for hydraulic cylinders. This adherence to industry standards ensures compatibility and reliability, critical factors as industries push for more sustainable energy solutions.

**Tip:** When considering hydraulic cylinder options, always evaluate the materials used in construction. High-strength alloys not only enhance durability but also improve the overall efficiency of hydraulic systems, contributing to long-term cost savings. Additionally, opting for cylinders that comply with recognized industry standards can significantly mitigate operational risks and enhance safety in application environments.

Understanding Hydraulic Pistons: The Key to Efficient Energy Systems Explained - Industry Standards and Innovations in Hydraulic Cylinder Technology

| Dimension | Standard Measurement | Material Used | Innovative Features | Application Areas |

|---|---|---|---|---|

| Bore Diameter | 50 mm - 300 mm | Steel, Aluminum | Anti-wear Coatings | Construction, Manufacturing |

| Stroke Length | 100 mm - 1000 mm | Carbon Steel | Cushioning Systems | Automotive, Aerospace |

| Pressure Rating | 10 MPa - 35 MPa | Stainless Steel | Load Sensing Technology | Agriculture, Mining |

| Weight | 5 kg - 500 kg | Alloy Composites | Compact Design | Marine, Oil & Gas |

| Cycle Time | 0.1 s - 3 s | Titanium Alloys | Smart Sensors Integration | Robotics, Packaging |

Real-World Applications: Hydraulic Pistons in Renewable Energy Systems

Hydraulic pistons play a crucial role in the efficiency of renewable energy systems, particularly in hydraulic power generation and bioenergy applications. According to a report by the International Renewable Energy Agency (IRENA), hydraulic systems can convert as much as 90% of the input energy into mechanical power, significantly higher than traditional mechanical systems. This efficiency is paramount in renewable energy, where maximizing output while minimizing waste is essential for sustainable energy solutions.

Real-world applications of hydraulic pistons can be observed in various renewable technologies. For instance, in tidal energy systems, hydraulic pistons are employed in the conversion of ocean and river currents into usable electricity. These systems harness the kinetic energy of water, with studies showing potential energy outputs ranging from 2 to 5 MW per installation, depending on the technology used. Additionally, in biomass energy production, hydraulic pistons manage the compression and transport of biofuels, streamlining processes and reducing energy consumption by up to 30%. The integration of hydraulic systems in these applications not only enhances efficiency but also supports the goal of reducing greenhouse gas emissions in the energy sector.

Related Posts

-

Essential Checklist for Choosing the Best Hydraulic Parts for Your Industrial Needs

-

Comprehensive Handbook to Mastering Hydraulic Equipment Repair for Global Buyers

-

Unlocking Global Supply Chains How to Identify Top Suppliers for Best Hydraulic Parts

-

Exploring Innovative Examples of Best Hydraulic Solutions for Your Business Needs

-

Maximizing ROI: The Hidden Benefits of Pump Repair Services for Global Buyers

-

5 Reasons Why Our Best Hydraulic Parts Outperform Competitors by 70% in Performance Tests

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com